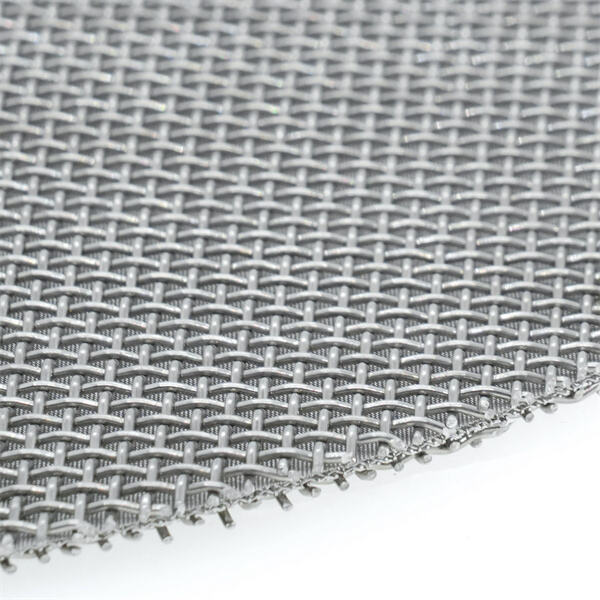

Woven wire mesh is a type of material that consists of thin wires that are interlocked together. This bears a robust, adaptable, network that can be applied in a number of ways. According to what each job requires, woven wire mesh can be made in different sizes and shapes. Since woven wire mesh does this role well, people use it as filter when they require such material. It can also prevent unwanted particles from passing through and allow clean substances to easily pass through.

There are many key advantages of woven wire meshs that make them suitable for various applications. This is particularly useful because fine particles of differing sizes can get caught within the filters. The size of the openings in the mesh, or the size of the mesh itself, determines what size of particles can pass through. This allows us to catch specific particles, so woven wire mesh filters can be made to just the right size to catch them for the job.

These filters have another great advantage which is their strength and durability. Woven wire mesh filter is constructed from robust materials that can withstand high pressures and temperatures without cracking. This feature makes them ideal for tough environments, like factories or environments working with hot liquids, where still, they can operate without damage.

Selecting a stainless woven wire mesh best suited for your application may prove a challenge at times. You need to consider what size of particles you want to eliminate. You’ll also need to think about filter pressure and temperature, as these can affect what kind of filter you get. The type of woven wire mesh filter that is right for you may also depend on the chemical properties of the things you need to filter.

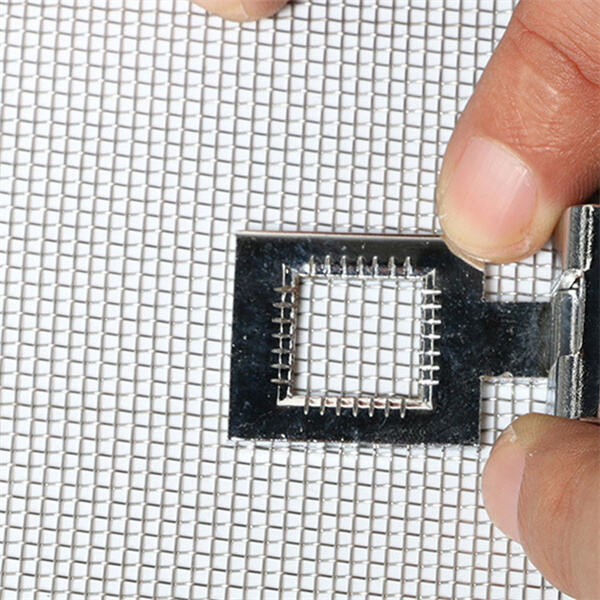

You may enhance the efficiency of woven wire mesh filters by customizing them to your precise requirements. By selecting a different shape and size of the filter, you make sure that it works well for the particular task you want it to perform. Tailoring this filter prevents it from obstructing clean compounds by facilitating their movement through it whilst still retaining the particulates that you wish to isolate

They can be made from various metals, including stainless steel, brass and copper This versatility allows them to be beneficial in numerous industries such as automotive, aerospace, and food processing. They help in the automotive industry by helping to keep engines clean, and in food processing areas, they keep food safe and uncontaminated.

Xuancheng woven wire mesh filters are sturdy and durable as they are made of high-quality materials. They can also be adapted to the specific needs of diverse use cases. No matter which kind of a filter is ideal for your application — air filtration, water filtration or chemical filtration, Xuancheng has the solution with the perfect fit.

A skilled team of after-sales service is available to provide full technical and customer service. This can be done via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to get their feedback on their current usage of filters and future expectations. By collecting customer feedback and issues that arise in the service after sales department, it can respond rapidly and give timely treatment or respond. At the same time the feedback is passed back to the design department or production department to promote the constant improvement of products and services. The expert team analyzes the root of the problem and provides solutions to make it less likely to occur repeating. When the two are in harmony, can we provide customers with an exceptional after-sales customer experience. This improves customer satisfaction and helps the growth of the enterprise.

Yangzhou Xuancheng Filter Screen Co., Ltd. is a reputable manufacturer of extruder filter, which has been dedicated for many years to the creation and development of extrusion-based plastic filters and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other products, as well as the filtering of chemical fiber spinning and other industries. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt, wire mesh mist eliminator, etc. With a wide assortment to meet the demands of various clients. The company has offered services to more than 500 famous plastic, petrochemical and metallurgical production companies across the globe, and has a broad market coverage and strong impact on brand image. The company has a strong technological force, high degree of specialization, complete production equipment and an extensive testing process. The company has been accredited with ISO9001:2015 to ensure the stability and reliability of its product.

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy