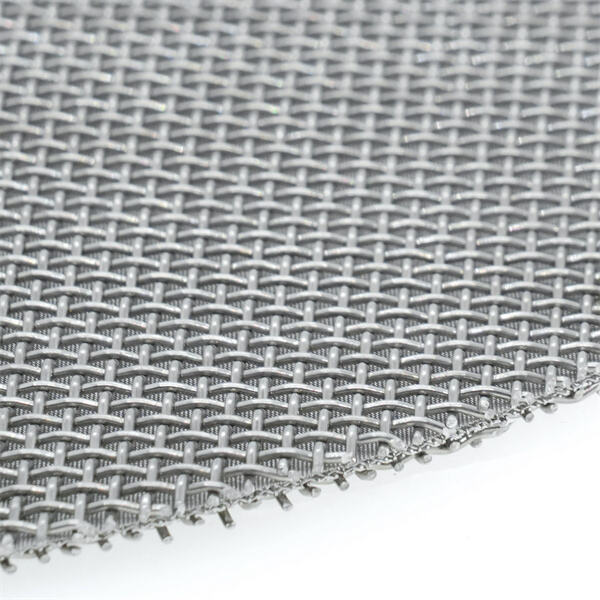

الشبكة السلكية المنسوجة هي نوع من المادة يتكون من أسلاك رفيعة متداخلة معًا. هذا يشكل شبكة قوية ومُلائمة يمكن تطبيقها بعدة طرق. بناءً على ما تتطلبه كل وظيفة، يمكن صنع الشبكة السلكية المنسوجة بأحجام وأشكال مختلفة. نظرًا لأن الشبكة السلكية المنسوجة تقوم بهذا الدور بشكل جيد، يستخدمها الناس كمرشح عندما يحتاجون إلى مثل هذه المادة. كما يمكنها منع الجزيئات غير المرغوب فيها من العبور والسماح للمواد النظيفة بالعبور بسهولة.

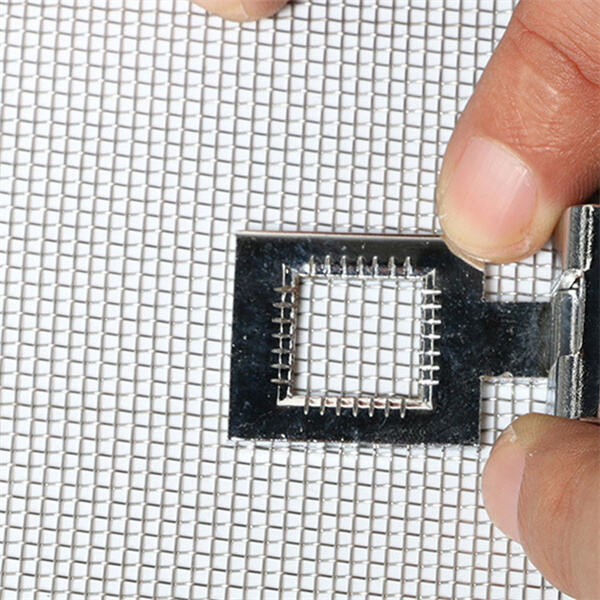

هناك العديد من المزايا الرئيسية لـ شبكة سلكية منسوجة هي التي تجعلها مناسبة لتطبيقات مختلفة. هذا مفيد بشكل خاص لأن الجزيئات الدقيقة بحجم مختلف يمكن أن تعلق داخل الفلاتر. حجم الفتحات في الشبكة، أو حجم الشبكة نفسها، يحدد حجم الجزيئات التي يمكنها المرور. هذا يسمح لنا باصطياد جزيئات معينة، لذلك يمكن صنع فلاتر الشبكة المنسوجة بالحجم المناسب لاصطيادها حسب الحاجة.

لدى هذه الفلاتر ميزة رائعة أخرى وهي قوتها ومتانتها. يتم تصنيع فلتر الشبكة المعدنية المنسوجة من مواد قوية يمكنها تحمل الضغوط والدرجات الحرارية العالية دون التشقق. هذه الخاصية تجعلها مثالية للبيئات القاسية، مثل المصانع أو البيئات التي تعمل مع السوائل الساخنة، حيث لا تزال قادرة على العمل بدون تلف.

اختيار شبكة سلكية منسوجة مقاومة للصدأ أنسب نوع لتطبيقك قد يشكل تحديًا في بعض الأحيان. تحتاج إلى التفكير في حجم الجزيئات التي تريد التخلص منها. ستحتاج أيضًا إلى التفكير في ضغط الفلتر ودرجة حرارته، لأن هذه الأمور يمكن أن تؤثر على النوع الذي ستحصل عليه. قد يعتمد النوع المناسب لك من فلتر الشبكة المعدنية المنسوجة أيضًا على الخصائص الكيميائية للمواد التي تحتاج إلى تصفيتها.

يمكنك تحسين كفاءة فلاتر الشباك السلكية المنسوجة عن طريق تخصيصها وفقًا لمتطلباتك الدقيقة. من خلال اختيار شكل وحجم مختلف للفلتر، فإنك تتأكد من أنه يعمل بشكل جيد للعملية المحددة التي تريد تنفيذها. تعديل هذا الفلتر يمنعه من عرقلة المواد النظيفة عن طريق تسهيل حركتها من خلاله مع الحفاظ في الوقت نفسه على الجزيئات التي ترغب في عزلها.

يمكن تصنيعها من مجموعة متنوعة من المعادن، بما في ذلك الفولاذ المقاوم للصدأ والنحاس والبرونز. هذه المرونة تجعلها مفيدة في العديد من الصناعات مثل السيارات، والطيران، ومعالجة الأغذية. فهي تساعد في صناعة السيارات عن طريق المساعدة في الحفاظ على نظافة المحركات، وفي مجال معالجة الأغذية، تضمن سلامة الغذاء ومنع التلوث.

فلاتر الشبكة السلكية المنسوجة من شوانغتشنغ قوية ودائمة لأنها مصنوعة من مواد عالية الجودة. كما يمكن تكييفها لتلبية الاحتياجات الخاصة لحالات الاستخدام المختلفة. بغض النظر عن نوع الفلتر المناسب لتطبيقك - سواءً كان ترشيح الهواء، أو ترشيح المياه أو ترشيح المواد الكيميائية، فإن شوانغتشنغ لديها الحل المناسب تمامًا.

يتوفر فريق ماهر من خدمة ما بعد البيع لتقديم الدعم الفني الكامل وخدمة العملاء. يمكن القيام بذلك من خلال خدمة عملاء الشركة، أو خدمة العملاء عبر الإنترنت ووسائل التواصل الاجتماعي. ستحافظ الشركة على التواصل المستمر مع العملاء بعد عملية البيع للحصول على آرائهم حول استخدامهم الحالي للフィلترات والتوقعات المستقبلية. عن طريق جمع ملاحظات العملاء والمشكلات التي تظهر في قسم خدمة ما بعد البيع، يمكن للشركة الاستجابة بسرعة وتقديم حلول فورية. وفي الوقت نفسه، يتم إرسال هذه الملاحظات إلى قسم التصميم أو الإنتاج لتعزيز تحسين المنتجات والخدمات بشكل مستمر. يقوم الفريق المتخصص بتحليل جذور المشكلة وتقديم الحلول لجعلها أقل احتمالاً للتكرار. عندما يكون هناك تناغم بين الاثنين، يمكننا تقديم تجربة استثنائية لعملائنا في خدمة ما بعد البيع. هذا يعزز رضا العملاء ويساعد في نمو المؤسسة.

شركة Yangzhou Xuancheng Filter Screen Co., Ltd. هي شركة تصنيع موثوقة لفلتر المُضغّات، وقد خصصت جهودها لسنوات عديدة لتطوير وابتكار فلاتر بلاستيكية بالاستناد إلى عملية التشكيل بالإخراج، ولديها تراكم تقني عميق ومعرفة واسعة في الصناعة. يتم استخدام هذه الفلاتر بشكل واسع في إعادة تدوير حبيبات البلاستيك، وإنتاج الأفلام والألواح وغيرها من المنتجات، بالإضافة إلى ترشيح صناعات مثل غزل الألياف الكيميائية. تتضمن منتجاتها فلاتر، شبكات حدودية، شبكات مقاومة تم لحامها بالنقاط، أحزمة شبكة فولاذية غير قابلة للصدأ ذات تعزيز أوتوماتيكي، وأحزمة ناقلة، وشبكات إزالة الضباب السلكية وما إلى ذلك. توفر الشركة مجموعة واسعة من المنتجات لتلبية احتياجات العملاء المختلفين. قدّمت الشركة خدماتها لأكثر من 500 شركة معروفة في مجالات الإنتاج البلاستيكي والنفطي والميتاليورجي حول العالم، ولديها تغطية سوقية واسعة وتأثير قوي على صورة العلامة التجارية. تتمتع الشركة بقوة تقنية كبيرة، ودرجة عالية من التخصص، ومعدات إنتاج كاملة وعملية اختبار واسعة. كما حصلت الشركة على شهادة ISO9001:2015 لضمان استقرار وموثوقية منتجاتها.

يُصنع مرشح المُخرِج من فولاذ عالي الجودة ويتميز بمسام صغيرة جدًا لتصفية المواد. هذا يسمح له بإزالة الشوائب وتحسين جودة ونقاء البوليمر. تم تصميم المرشح بحيث يضمن تدفق المادة بشكل ثابت، مما يوفر كفاءة تصفية مستقرة أثناء مرور المادة عبر هذا المرشح، مما يقلل من انسداده ويزيد من كفاءة الإنتاج. يتمتع المرشح المعدني بمقاومة عالية للتآكل والحرارة العالية. بناءً على المتطلبات الخاصة للعميل ومعلمات المُخرِج، يمكن إنشاء حلول مرشح مخصصة لضمان التوافق الكامل مع المعدات الموجودة والحصول على أفضل النتائج في الترشيح. يعمل نظام تصفية عالي الأداء على تقليل الوقت الضائع بسبب الانقطاعات الناجمة عن انسداد الشوائب وزيادة الإنتاجية.

تتضمن الخدمات المخصصة اختيار أبعاد مادة الفلتر، وحجم وشكل المسامات، بالإضافة إلى عناصر أخرى. كما يمكنها توفير فلاتر مخصصة وفقًا لاحتياجات العملاء ومواصفات المُذيب. من خلال الخدمات المخصصة، يمكن تعديل بنية المرشح وكذلك المادة، وكفاءة الترشيح والمعلمات الأخرى، مما يساهم في تحسين كفاءته في الترشيح وزيادة عمر المرشح. يتم تصميم العملية وفقًا لاحتياجات العميل، مما يتجنب الهدر الزائد لتقليل تكلفة العملاء. اختر المواد ذات الخصائص المناسبة التي تلبي متطلبات العميل مع الأخذ بعين الاعتبار الحاجة إلى مقاومة الحرارة، ومقاومة الاحتكاك وما إلى ذلك. بناءً على إعداد الاستخدام وظروف التركيب، قم بتصميم هيكل مرشح معقول، مثل أنواع الألواح، أو الأنواع الملتفة أو الأسطوانية، على سبيل المثال.

جميع الحقوق محفوظة © شركة يانغتشو شوانشينغ لصناعة الشاشات المرشحة المحدودة - سياسة الخصوصية