The point is machines allow us to save so much time and effort doing everything. We employ them to carry out tasks that would be laborious or time consuming for us to execute ourselves. However, every now and then tiny particles can be detrimental to the machines in operation. Machine functionality – these small particles have the capability of disrupting how a machine functions and eventually harming it. Here are where filters come into play! These tiny particles will then be caught by the filters, similar to small screens which makes machines work well and have a longer life. Filters can be used to ensure that no disturbance due to the blocking happens and systems keep on functioning without flaws.

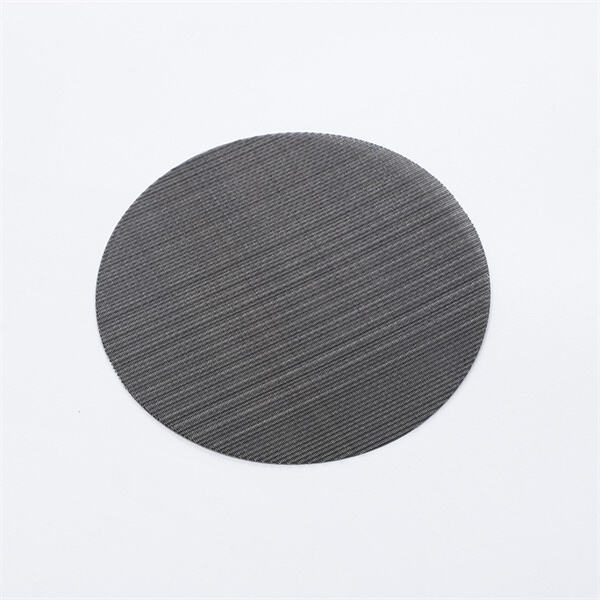

Well, Mesh Filter Mild Steel is manufactured from a steel that generally known as mild steel. The metal can support a great deal of weight (even many times the human body mass!) hence why it is used in so many different places. The filter consists of minuscule metal wires intertwined to form a knitted mesh. This mesh features many small holes that will trap foreign particulates, yet not restrict air or liquid flow in a significant way. As it is constructed from steel, Mild Steel Filter Mesh ranks high on the durability list and can be operated relentlessly for a prolonged period — which means you could rely upon these filter meshes even when filters need to bear plenty of load & wear being exposed.

Mild Steel Filter Mesh is good, and one of the key features for it can work under hot conditions. So, even if it goes insanely hot your filter would still be doing an amazing job. And it is also very easy to clean! The extra dust particles can be shaken off or washed with water, meaning it is easy to maintain. Mild Steel filter mesh is also available in variety of shapes and sizes This makes it a multi-purpose language and can be adapted to several use cases making it an undeniable choice for different sectors!!

Factories are the place where different types of materials produced by machine that cause damage if not controlled. Things like dust, dirt and other little particles can form a blockage. Filters made up of Mild Steel Filter Mesh prove to be ideal under this case as these save machines from such foul particles. These particles of dirt and other debris cause machines to work less efficiently, creating the need for repairs or replacements more often. This does not only safe money in terms of repair but it also keeps the production running well. Stainless steel, mild and fine metal mesh can resist corrosion. It is very dependable and powerful, which is why a great many industries including auto manufacturing, aviation etc. rely on it to make their products.

Mild Steel Filter Mesh: It is provided as a filter and used for dust, trash particles to removal of liquids. These filters can be applied in a wide array of machines to keep them protected, thus assisting these devices run smoothly for years. There are many categories of Mild Steel Filter Mesh in Xuancheng to suit the needs of different jobs and industries. There are solutions that will best fit your need, so whether you require a filter for a small machine or large industrial system is not an issue.

Filter made from Mild Steel Filter Mesh are used in numerous industries for multiple applications. Car engines, mining and oil production processes, heavy machinery — the same place where we get gas for our homes – all rely on reliable large hardware use in addition to construction machines. These filters also have other uses, for example in air conditioning systems where they take out all the dust and allergens from the air; this is necessary to a healthy environment. They also appear in large machines such as bulldozers and excavators to filter oils and fluids that are necessary for the machine's proper operation. These filters are also used in water treatment plants to make the water healthy while extracting other dangerous components from it.

The filter in the extruder is constructed of top-quality metal, and it has tiny pores for filtering. This permits it to eliminate impurities and improve the purity and quality of the polymer. The structure of the filter is designed to ensure that the material flow remains stable in filtration throughout its passage, reducing clogging and improving production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. Filter products that are custom-designed can be found to meet the requirements of different customers, and to match the equipment. A high-performance filtration system reduces the amount of delays caused by clogging of impurities and boosts the productivity.

The customized service consists of choice of the size of the filter's pore along with the shape, material and other aspects and will provide customized filters that meet the specific requirements of each customer and the particular specifications of the extruder. Customized services enable the optimization of parameters for filtering like structure, material, filtration precision and many more. This improves the filter's filtration efficiency and life. The production process is conducted in accordance with the needs of the customers, while avoiding unnecessary waste in order to save customers money. According to the specific needs and application scenarios of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance as well as wear resistance, high temperature resistance, etc. Select materials with the same properties, for example galvanized iron, stainless steel and more. Make sure the filter you design is appropriate for the installation and usage conditions of your client.

A skilled team of after-sales services is on hand to provide complete technical and service support. This can be done by calling the company's number, online customer service and social media. When the products are purchased, regular communication with the buyer is conducted to gain an understanding of the usage of their filters, as well as the future requirements and expectations. The after-sales team can address customer concerns and feedback quickly by collecting the details. Additionally, feedback from customers is also passed back to the product design and production departments in order to improve the quality of products and services. The experienced team examines the root of the problem and provides key solutions to decrease the frequency of this issue. Only when the two complement each other can we give customers an exceptional after-sales customer experience. This enhances customer loyalty and aids in the long-term growth of the enterprise.

Yangzhou Xuancheng Filter Screen Co., Ltd., one of the producers of extruder screening has been devoted to the development and production of plastic extrusion filters for a number of years. They have amassed the most extensive technical knowledge and have gained experience in this business. They are extensively used in the industries of plastic granulations modified by granulations recycling granulations, extrusions made of sheets and films, and many others along with the filtration of chemical fibers. There is a broad range of products that include filters, edging meshes, spot-welded meshes stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators and so on. offering a variety to meet the varied needs of the customers. It has provided services to more than 500 prominent plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great branding influence. The company has a high technical power, a high degree of specialization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy