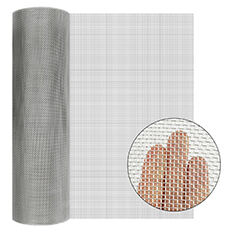

Woven Wire Mesh may not seem like everything exciting at first, but once you take a closer look to it than there is an enormous deal going on. Hence today we are going to pull wide-open the paradigm of woven wire mesh. This Filter Discs material is called so, because it comprises a rigid frame-mesh grid manufactured by interweaving wires. These wires could be made up of any components used to wrap around steel, aluminum or brass. In addition to wire mesh panels, Xuancheng also has a wide selection of woven wire meshes with high quality that are used widely.

The most critical role of woven wire mesh fences is its transparency. It obstructs the view, not like regular wooden or stone walls. Good because you can have the ability to understand what results on the opposing of one's fence which assists maintain a wrist over trespassers. On the other hand, their transparency allows for better air circulation and sunlight. Most of all they are useful on farms where animals need fresh air and sunlight to be healthy and happy.

While cladding is the most-common type of application you might use woven wire mesh for, fencing provides another easy example. It is very versatile. Such as Window Screen: Bird Cage or even mesh bags for clothes washing. The Filter Screen Pack and is excellent for strength, as well when you use it in gardening/landscaping projects. This serves two purposes- makes the plants healthy and big, and also make your garden more vibrant.

Manufacturers ( from factories and in general industries) use Xuancheng woven wire mesh all the time. For filters and sieve screens: It doesn't because it can be customized to only that which is required. This could be filtering small particulate from liquids for instance, or utilizing it in the separation of disparate materials. One other common aspect of woven wire mesh is in the creation of conveyor belts and many different types of equipment designed for moving goods. It is exceptionally longs lasting and inexpensive which makes it suitable for these types of industrial applications.

Woven wire mesh of Xuancheng is being used for architectural purposes in some recent years. Usually those are used in the ceilings and walls, but also as partitioning solutions. One of the reasons for its use is to capture light into the rooms and other protected areas. It can improve the condition of a room by making it feel more spacious and inviting. This ss wire mesh, moreover is a rather beautiful and modern architectural resolution to many building solutions. Even outside of buildings, the product can be used to help create a new fashionable facade in darkness. Cool roofs do reduce energy costs for keeping buildings cooler.

Customized services involve the selection of filter material, pore size and shape in addition to other aspects. They can also provide personalized filters to meet customer specifications and requirements for extruders. With the help of customized services, structure, material, filtration accuracy and other parameters of the filter can be improved in order to increase its efficiency at filtration and prolong its service life. The process is designed according to the specific requirements of the customer, and avoids unnecessary waste, so as to save customers money. Choose the materials with most suitable properties for the requirements and needs of the client, taking into account the needs for heat resistance, corrosion resistance, wear resistance etc. Choose a filtering structure that is appropriate for the location and usage conditions of your client.

The company is equipped with a skilled after-sales team, utilizing the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical support, consultation on products and tracking cargo along with troubleshooting services. The company will communicate with customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the details. In addition, the feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The team of experts thoroughly investigates the cause of the issue, and then provides basic solutions to minimize the chance of repeating the same issue. Both complement each other and it is only then that we can offer our customers a high-quality after-sales experience. This in turn will strengthen customer loyalty and aid in helping the business increase its growth.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

The filter in the extruder is made of premium metal with very fine pores. This helps to eliminate contaminants and enhance the quality and purity of the polymer. The structure of the filter is designed to ensure a high efficiency in filtration while the material is flowing through it, thus reducing the possibility of the likelihood of clogging. This increases the efficiency of production. The metal filter is highly resistant to resistance to corrosion, wear and high temperatures. Customized filter products are available to satisfy the requirements of different clients, and also to fit with the equipment. A high-performance filtration system decreases the time lost to interruptions caused by the accumulation of impurities and boosts the productivity.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy