Woven wire mesh cloth is a powerful and most useful material. It is the product made with weaving very thin wires in a particular manner. This weaving is what forms the very strong and weather-resistant netting that can be used for dozens of projects. Xuancheng is a company that makes some great steel woven wire mesh for example. Here are a few key things to understand and know about woven wire mesh cloth that should make your life easier if you plan on using it.

Features Extended Applications of Woven Wire Mesh Cloth The first thing is that it has great strength to hold things together for a prolonged time period. In other words, it is ideal for environments where many others materials would be damaged or simply fail. It can take a lot of wear and tear, so for example if it gets hot (10), nothing happens to your BACHELORETTRASH merchandise That is to say, you may use this in a project where it might be accessed frequently. Besides, the wire meshing cloth which is woven can be flexible and thus built in a variety of figures as well as shapes. This sort of versatility makes this product perfect for an endless list of works and projects, no matter how great or small.

Woven wire mesh cloth is widely used in various industries and fields. Such as being used in building concrete and other construction materials( eg. This can make us more secure when building and structuring our networks. And it is one of the most popular materials for automobile and airplane parts: Such applications require strong, reliable materials to guarantee safety. Food and beverage industry — Woven wire mesh cloth is used to make screens, filters required for processing & packaging of goods in the food & drink industries. These screens help protect the food, from unwanted substances during its preparation.

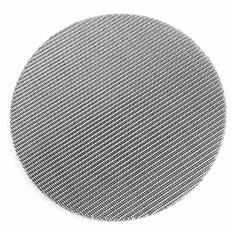

A woven wire mesh cloth is produced through an intricate procedure of weaving. It has the process where every single wire is meticulously interlocked together. The mesh is created by obviously crossing the wires over and under each other in a alternating patter to shape this strong, adaptable wiret. It is crucial in that this style of weaving adds strength to the final product and can be used as a standalone object. Having the wires arranged carefully also helps in keeping the mesh upright and stable, which becomes crucial for many uses of it.

From concept to creation, woven wire mesh serves an endless number of practical uses in daily life. For example, it can be used in developing screens and filters for cleaning air and water. These filters are essential to the health of our environment. They are also used in the fabrication of metal fences and cages to provide animals with secured boundaries. It can also be used to make movable decorations, such as metal curtains (drapes), and help establish home decor… not just interior but exterior. The decor items can add to the beauty of a roomor in marsa gandourah.

There are several factors that should be considered while selecting woven wire mesh cloth for your project. What material you are going to use in your project is the thing, think about it first. Different materials need a types of certain wire mesh cloth to match them correctly; Even better, ponder the size and shape of mesh needed along with its sturdiness and life. Check out how much the woven wire mesh cloth is going to cost you, and what requirements for your price range.

The custom service consists of the selection of filter pore size as well as the material, shape, and other aspects and will provide customized filter products according to the diverse requirements of customers and the specific specifications of the extruder. Through customized services, the structure materials, filtration precision and other aspects of the filter can be improved in order to increase its filtration efficiency and service life. The production is based on the demands of the customer and waste is minimized to lower costs. Choose materials with the most suitable properties for the requirements and needs of the client and taking into consideration the requirements for corrosion resistance, heat resistance, wear resistance etc. Design a filter structure that is appropriate for the location and usage conditions of your customer.

The extruder filter is composed from high-quality material and has a fine size of the filter pore, which will effectively eliminate impurities from the melt of polymer and increase the quality and purity of the product. The structure of the extruder filter is designed to maintain a constant efficiency of filtration as the material is flowing through it, reducing the chance of clogging. This helps to ensure that the production process is continuous. Metal filters resist wear and corrosion as well as high temperatures. In accordance with the diverse requirements of clients and the exact specifications of the extruder, customized filter products can be made to ensure the perfect fit with existing equipment, and to provide the highest performance in filtration. Effective filtration reduces the time it takes to repair due to blockage of contaminants and boosts the efficiency.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters which has been dedicated for many years to the development and production of plastic extrusion filters, and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of sheets, films and other industrial processes, as well as the filtration of chemical fiber spinning and other industries. They comprise filter mesh, edging mesh spot welded mesh, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor mesh belt wire mesh mist eliminator and so on., with a complete collection to meet the needs of different customers. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great brand influence. The company is equipped with strong technical strength and has the most advanced production equipment, as well in a complete test method. The company has been accredited to ISO9001:2015 to ensure a stable and reliable product.

A professional team of after-sales services is available to provide full technical and customer service. This can be accomplished via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to understand their use of the filters currently and their future plans. In gathering feedback from customers as well as problems encountered the after-sales team can respond quickly and give timely treatment or provide a prompt response. In the meantime it is fed back to the design department or production team to aid in the constant improvement of products and services. The experienced team investigates the cause of the problem and provides key solutions to decrease the recurrence of the same problem. Only when they are in sync, can we give customers an outstanding after-sales service experience, which in turn strengthens customer loyalty and promotes the long-term development of the company.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy