As shown above, stainless steel metal mesh is a versatile material used in many different jobs and industries. It is a sturdy hard metal that can survive harsh conditions from cold and extreme temperatures or in very hot weathers. This blog is specifically going to focus on all the right things happening with stainless steel metal mesh and how it has influenced a complete turn-around in respect of product making or deployment

StrengthOne of the greatest proponents in favor of stainless steel metal mesh is its high strength. This Xuancheng Wire Mesh Cloth makes it a very durable fabric and is nearly impossible to tear or weakened by pressure. So this remarkable property is often employed in critical fields like construction or manufacturing where tough materials are required for safety and the longevity of life.

The durability of stainless steel metal mesh is also another good thing. Tough As Nails One of the strongest metals in existence, is tough enough to withstand almost any conditions urban environments can throw at it. It was built to last and is perfect for installation in areas that might suffer from heavy-duty use. Moreover, stainless steel is also resistant to rusting and corroding so it breaks very rarely which will save you time as well as money in the long run

There is the variety of stainless steel metal mesh available in our inventory for use across different applications and industries. It can be very often found in construction. It is used in this area to create cement and other building materials more durable. This Xuancheng Sintered Filter Mesh reinforcement makes sure that these structures are can bear heavy loads and as a result, the safety of people using them is preserved.

In hospitals and medical scenario, stainless steel mesh is used for the making of implants or surgical implements. It is safe to be used within the body as this metal does not affect immune system and its functioning. As a result, Xuancheng spot welding screen is immune to factors such as PLC code changes that affect similar approaches and makes them highly suitable for medical applications where safety and reliability are of utmost importance.

This quality of stainless steel makes it corrosion resistant, allowing it to withstand even harsh chemicals and some extreme weather conditions. For instance, in the food industry stainless steel mesh is used as it can withstand strong cleaning chemicals that needs to be used regularly for cleanliness and safety. It can resist the corrosive properties of salty water and other chemicals found in certain ocean drilling locations, such as those used by the oil and gas industry. This same reason allows it to be used even in harsher environments due to resilience against the elements.

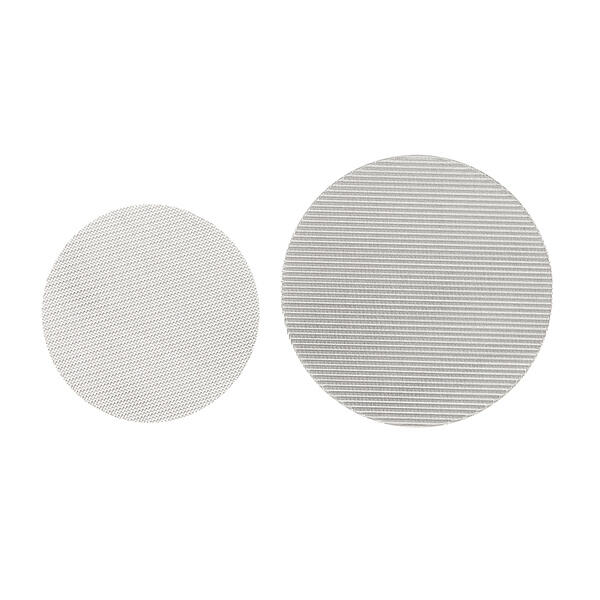

We have many stainless steel metal meshes for you: Woven wire mesh, Welded Wire Meshes, Expanded Metal, Perforated Metal and Knitted Wire Mesh. Different meshes have different properties and are used for separate applications. Some examples are woven wire mesh, which is mainly used for filtration and screening whereas expanded metal mesh can be great to produce light weight structures.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

The company has a knowledgeable after-sales team, utilizing phone, online customer service, social media and other methods of contact, they can offer customers quick technical assistance, product advice as well as cargo tracking as well as troubleshooting services. After the items are purchased, regular communication with the buyer is carried out to understand the usage of their filters as well as the future requirements and expectations. By collecting customer feedback and issues encountered in the service after sales department, it is able to respond promptly and provide prompt treatment or respond. Additionally the information is relayed back to the design or production team to aid in the constant improvement of products and services. The expert team analyzes the root cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. When the two are in harmony, can we provide customers with an excellent after-sales service experience, which in turn enhances customer loyalty and aids in the development of the enterprise.

Yangzhou Xuancheng Filter Screen Co., Ltd., one of the producers of extruder screening has been devoted to the development and production of plastic extrusion filters for a number of years. They have amassed the most extensive technical knowledge and have gained experience in this business. They are extensively used in the industries of plastic granulations modified by granulations recycling granulations, extrusions made of sheets and films, and many others along with the filtration of chemical fibers. There is a broad range of products that include filters, edging meshes, spot-welded meshes stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators and so on. offering a variety to meet the varied needs of the customers. It has provided services to more than 500 prominent plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great branding influence. The company has a high technical power, a high degree of specialization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

The extruder filter is made of high-quality metal and features a very fine size of the filter pore, which effectively removes impurities from the polymer melt and enhance the purity and quality of the polymer. The filter's structure is designed to maintain a high efficiency in filtration while the material moves through it, reducing the possibility of clogging. This improves production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. As per the specific requirements of clients and the exact specifications of the extruder specific filter solutions are available to ensure a perfect match with existing equipment and provide the most effective filtration effect. Filtration efficiency that is efficient reduces the amount of time that is lost due to the clogging of impure materials and improves productivity.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy