Mild Steel Woven Wire MeshBy:Xuancheng It is an innovative kind of metal wire with a lot of features and advantages. So, if you want to know why this wire mesh is the best for your use then hang on. This would provide an example of everything in simple.

Mild Steel Woven Wire Mesh is a metal wire type element which use shape of grid to make a solid structure.mesh/mesh. This wiring method is not only effective but also makes the mesh very tough. It is made out of a specific type of steel, which provides it with its tensile strength and durability. As we mentioned previously, the mesh can be entirely different in size and shape thus allowing it to have a big variety of uses. Whether you need a fragment fine enough for an arts and crafts project, or pane sharp enough to build something with.

Strength: The best thing about the Mild Steel Woven Wire Mesh is that it is very strong. For more cable support missions which require strength, this is a good news. It is, for instance used when constructing walls and floors to make things more solid. Its use extends to making cages for animals, ensuring that they are kept safe and secure.

Best thing about Mild Steel Woven Wire Mesh is that it cost not more. In fact, it is one of the cheaper metal wire mesh products on offer in Melbourne. But that's not to say it is a cheap alternative by any measure. For some applications, Mild Steel Woven Wire Mesh is still going to be one of the best options available — count on it every time.

There are many metal wire mesh in all shapes imaginable, but most people want to go with stainless filter screenes. Because that one is sturdy and has longevity. It is also rust-resistant that makes it ideal for outdoor use. Metal can deteriorate over time with rusting and become less useful, but not when you’re talking about Mild Steel Woven Wire Mesh.

Mild Steel Woven Wire Mesh is also one of the most versatile meshes. You can use it for many works and in various areas like construction, gardening or even art projects. Mild Steel Woven Wire Mesh is an excellent option for just about every application, whether you are using it to fabricate something strong or if your purpose could be considered light artwork.

Air Systems: It can be installed in air systems used to purify the air by trapping dust and dirt, thus making it more breathable for those in your home or business.

Yangzhou Xuancheng Filter Screen Co., Ltd., a manufacturer of extruder screens, has been dedicated to the design and manufacture of plastic extrusion filter for a long time. They have built up an extensive amount of technical know-how and have gained experience in this business. They are extensively used in the manufacture of granulations that are modified with plastic, recycling granulations, extrusions made of films and sheets and many more along with filters for spinning chemical fibers. There is a variety of products available, such as filters, edging meshes, spot-welded meshes stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators etc. with a full range that can meet the various requirements of our customers. The company has supplied more than 500 of the most prestigious plastic, petrochemical, and metallurgical firms around the world. The company's name is widely acknowledged and is able to cover a variety of markets. The company has strong technical force, an extremely high degree of particularization, complete production equipment and an extensive testing process. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

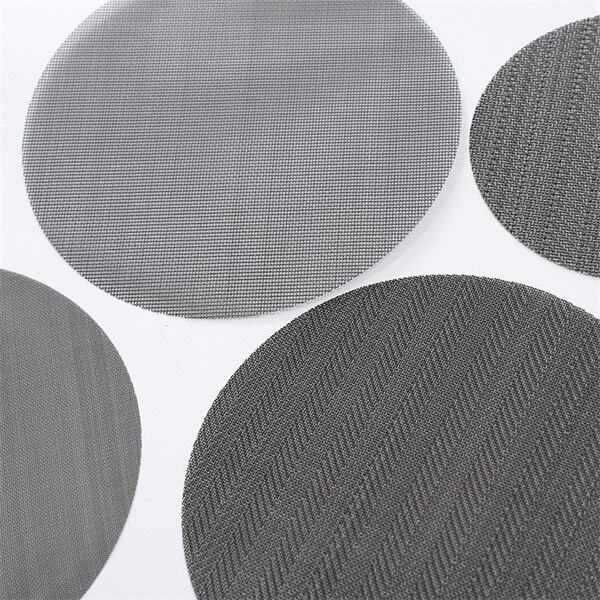

The extruder filter is made of high-quality metal and features a very fine size of the filter pore, which effectively removes impurities from the polymer melt and enhance the purity and quality of the polymer. The filter's structure is designed to maintain a high efficiency in filtration while the material moves through it, reducing the possibility of clogging. This improves production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. As per the specific requirements of clients and the exact specifications of the extruder specific filter solutions are available to ensure a perfect match with existing equipment and provide the most effective filtration effect. Filtration efficiency that is efficient reduces the amount of time that is lost due to the clogging of impure materials and improves productivity.

A professional team of after-sales services is available to provide full technical and customer service. This can be accomplished via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to understand their use of the filters currently and their future plans. In gathering feedback from customers as well as problems encountered the after-sales team can respond quickly and give timely treatment or provide a prompt response. In the meantime it is fed back to the design department or production team to aid in the constant improvement of products and services. The experienced team investigates the cause of the problem and provides key solutions to decrease the recurrence of the same problem. Only when they are in sync, can we give customers an outstanding after-sales service experience, which in turn strengthens customer loyalty and promotes the long-term development of the company.

The customized service consists of choice of the size of the filter's pore along with the shape, material and other aspects and will provide customized filters that meet the specific requirements of each customer and the particular specifications of the extruder. Customized services enable the optimization of parameters for filtering like structure, material, filtration precision and many more. This improves the filter's filtration efficiency and life. The production process is conducted in accordance with the needs of the customers, while avoiding unnecessary waste in order to save customers money. According to the specific needs and application scenarios of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance as well as wear resistance, high temperature resistance, etc. Select materials with the same properties, for example galvanized iron, stainless steel and more. Make sure the filter you design is appropriate for the installation and usage conditions of your client.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy