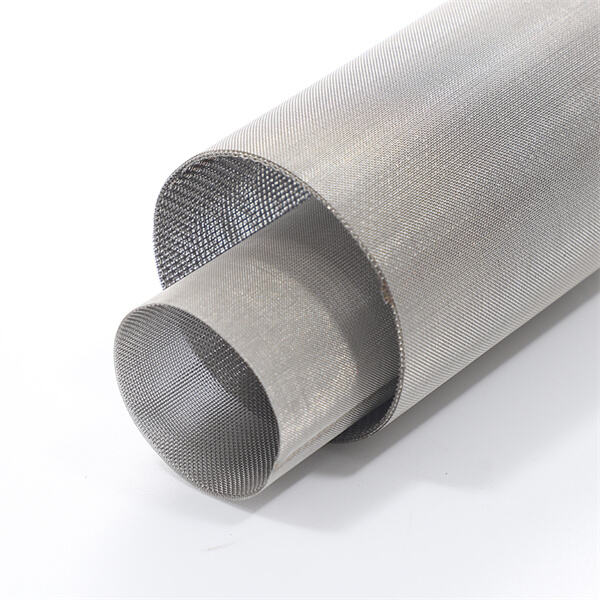

Stainless steel wire mesh tubes are indeed termed as special filters because of effectiveness in so many different circumstances. This is constructed with durable stainless steel so means these are strong and it will not be destroyed soon or rust. This makes them ideal for liquid/gas filtration in a wide range of industries such as food, medicine, mining and agriculture. Advantages: Xuancheng is one of best company to produce these s with good quality and very satisfactions.

Stainless steel wire mesh tube produced by Xuancheng is used for liquid and gas filtration in various industries. The tubes are made to filter out dirt and other unhealthy contaminants so that the end user has a clean, safe supply. This implies several sizes and forms, which make them suitable for a range of utilities and surroundings. Better yet, these tubes are simple to clean and last long before you need a replacement. This saves businesses money as they will not have to purchase new filters all the time.

Stainless Steel Wire Mesh Tube is a Filter Structure to Remove Dirt Particles, Solids and Impurities. They are lightweight and made of durable stainless steel wire mesh. There tubes can be found slipping through industries like food processing, car production and cleaning wastewater. Moreover these tubes are available in different sizes and shapes which makes them perfect for a variety of jobs. They manufacture stainless steel wire mesh tubes which are durable and reliable, hence complying with high-quality criteria.

Stainless steel demister pad manufacturer is one of the most significant tools that can be used in a variety of niches, especially when it comes to Xuancheng stainless steel wire mesh tubes. These can bear a lot of wear and tear given hot weather conditions, so are idle for work-related to industry. They are also quick and easy to install, require little maintenance once they installed. This has been a good way for businesses to offer services really cheap, the next time you get kicked out of your home because it was too late payment notice from being in foreclosure becaue and start saving money quickly. Whether you are in food processing, chemical production or mining, we have a stainless steel wire mesh tube for your requirements.

Stainless steel wire mesh tubes in Xuancheng can be used as effective tools for filtering different substancesin many industries. Then work efficiently to eliminate all kinds of dirt and unwanted particles from liquids or gases so the final product is clean. The tubes are built to last because they rarely need maintenance, or changing out for another tube which in turn saves cost of businesses as they do not have to replace them often. Xuancheng stainless steel wire mesh tube produced by the new network, you can rest assured that your filtration process is always reliable and effective.

The extruder is made of high-quality metal and features a small pores for the filter, which can effectively remove impurities from the melt of polymer as well as improve the quality and purity of the final product. The structure of the filter has been designed to ensure that the material flow remains stable in filtration as it passes through it, thus reducing the possibility of clogging and enhancing production continuity. Metal filters are invulnerable to corrosion, wear and high temperatures. According to the different needs of the customer and the specifications of the extruder specific filter solutions are available to ensure an ideal match with existing equipment and provide the most effective filtering effect. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and also increases the efficiency.

A skilled team of after-sales service is available to provide full technical and customer service. This can be done via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to get their feedback on their current usage of filters and future expectations. By collecting customer feedback and issues that arise in the service after sales department, it can respond rapidly and give timely treatment or respond. At the same time the feedback is passed back to the design department or production department to promote the constant improvement of products and services. The expert team analyzes the root of the problem and provides solutions to make it less likely to occur repeating. When the two are in harmony, can we provide customers with an exceptional after-sales customer experience. This improves customer satisfaction and helps the growth of the enterprise.

Yangzhou Xuancheng Filter Screen Co., Ltd., a manufacturer of extruder screens, has been dedicated to the design and manufacture of plastic extrusion filter for a long time. They have built up an extensive amount of technical know-how and have gained experience in this business. They are extensively used in the manufacture of granulations that are modified with plastic, recycling granulations, extrusions made of films and sheets and many more along with filters for spinning chemical fibers. There is a variety of products available, such as filters, edging meshes, spot-welded meshes stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators etc. with a full range that can meet the various requirements of our customers. The company has supplied more than 500 of the most prestigious plastic, petrochemical, and metallurgical firms around the world. The company's name is widely acknowledged and is able to cover a variety of markets. The company has strong technical force, an extremely high degree of particularization, complete production equipment and an extensive testing process. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy