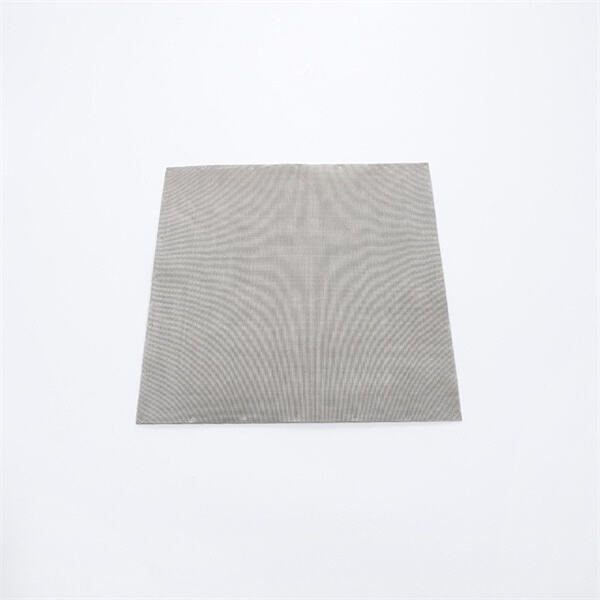

Stainless steel wire mesh filters are useful in a variety of applications and industries. These are used in farming, chemical plays and handling of oils. This Xuancheng ss wire mesh filter consist of multiple wires attached to each other having tiny gaps for passage of liquids or gases. The holes can be made bigger or smaller, depending on whatever the filter is being use for. It enables dozens of filters for different use cases.

Why people would love stainless filter screens is because they are very versatile. They are very versatile! For example, liquids can be filtered to eliminate impurities, substances of different types can be separated out and machines that process them are also protected from dust and dirt. Just as you're familiar with the strainer in your kitchen, holding back pieces from contaminating your soup or pasta. However, they can also function as a straining mechanism that separates materials of various sizes. They are especially helpful in guarding machines from potential harm.

Filtering is also crucial, as being efficient matters. On the other hand, Stainless steel wire mesh filters are designed to trap as many materials moisture during the filtering process. The wires are placed inside in a special manner that it allow easy passage of liquid or gas. This configuration causes the liquid or gas to travel through several layers of wire mesh, effectively capturing particles.

This is why multiple layers of wire mesh are so great with this type of filter- they do a much better job catching those tiny particles that would slip by. So, water and gases flow through Xuancheng fine stainless steel mesh screen rapidly making the latter effective solution for removal of dirt, pollutants, etc from liquids & gases. If you think about it, just clean liquids and gases are a very important thing for many processes and industries.

Stainless Steel Wire Mesh Filter: Many jobs and even business also which cannot recalculate the maintenance cost, result in choosing an extremely durable option such as a stainless steel wire mesh filter. These stainless steel filters are also much more durable and robust than other forms of filter-- they are not as delicate, nor do they often wear out. They resist rusting as well, so they will not corrode when caught in moisture. They also are impervious to harsh chemicals and high temperatures so will not break down.

Stainless steel filters are also very user-friendly and therefore easy to clean. If need be you can fully disassemble for a more aggressive clean but the steel mesh can easily just be wiped down with soap and water or light cleaner. They are highly versatile with very minimal maintenance and can be used many times over if handled well. This not only saves money, but it also keeps waste to a minimum.

Stainless steel filters is that have high durability, which is why stainless steel filters are widely used for water cleaning. They will not swell, distort or corrode despite of the potent chemicals and elevated water temperatures that can be present in a water treatment plant. Xuancheng stainless steel woven cloth last a lot and can be used multiple times over as they do not need to be changed as regularly other filters. Thus, they are suitable for commercial use where those specific filters may be an ideal selection.

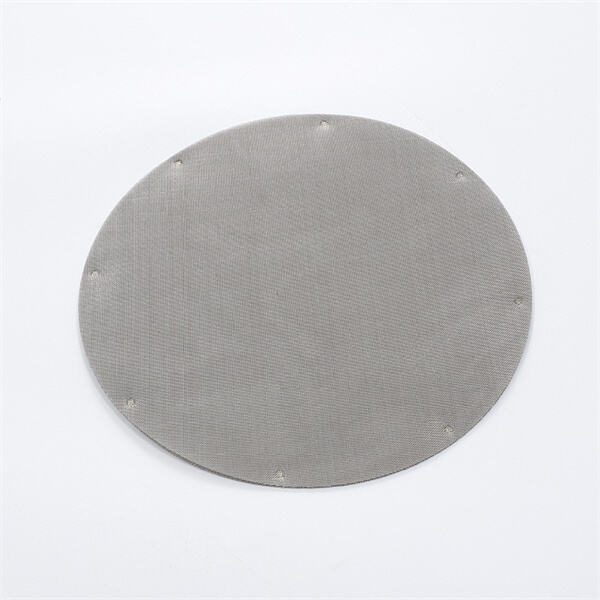

The extruder filter is made of high-quality metal and features a very fine size of the filter pore, which effectively removes impurities from the polymer melt and enhance the purity and quality of the polymer. The filter's structure is designed to maintain a high efficiency in filtration while the material moves through it, reducing the possibility of clogging. This improves production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. As per the specific requirements of clients and the exact specifications of the extruder specific filter solutions are available to ensure a perfect match with existing equipment and provide the most effective filtration effect. Filtration efficiency that is efficient reduces the amount of time that is lost due to the clogging of impure materials and improves productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters, which has long been committed to the production and development of extrusion filter made from plastic and has a vast amount of technical knowledge as well as industry knowledge. The products are widely used in the fields of plastic modified granulations recycling granulations, extrusions made of films and sheets and many other applications, as well as the filtration of chemical fibers. They include filters, edging mesh, spot welded mesh, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor belt, mist eliminator wire mesh, and so on. With a wide range to meet the needs of a variety of customers. It has provided services for more than 500 known plastic, petrochemical, and metallurgical production companies across the world, offering a wide markets and an impressive influence on the brand. The company has strong technical force, high degree of particularization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

The customized service includes the selection of filter pore size along with the shape, material as well as other elements and is able to provide custom filter products according to the different needs of customers and the specific specifications of the extruder. With the help of customized services, structure as well as the material, filtration efficiency and other aspects of the filter are able to be improved, so as to improve the efficiency of filtration and extend its the life of the filter. The process is designed according to the actual needs of the client, thus avoiding the waste that is unnecessary, and aiming to save customers money. In accordance with the specific requirements and applications of customers, taking into consideration the specific demands such as corrosion resistance and high temperature resistance wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron and more. Based on the use of the customer's surroundings and conditions for installation make sure you design a functional filtering structure, like types of plates, wound types or cylindrical type, for example.

The company has a professional after-sales team, utilizing the telephone, online customer support along with social media and other contact methods, can efficiently provide customers with technical support, product consultation as well as cargo tracking and troubleshooting, among other services. The company will contact customers regularly after the sale to find out their current usage of filters and to anticipate their needs for the future. By collecting customer feedback and problems encountered in the service after sales department, it is able to respond quickly and offer a prompt respond. Furthermore, feedback is also passed back to product design and production departments to enhance products and services. The team of experts thoroughly investigates the cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. Both complement each other and only then can we offer our customers a high-quality customer service. This improves customer loyalty and assist the company to expand.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy