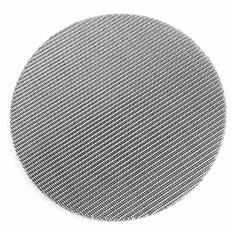

Have you ever heard of how dirty water looks can transform itself into clear, clean water? The answer is filtration of course. Another special process is to clean water by doing Filtration. This Xuancheng Filter Screen Pack process provides people with clean, safe water that is they can drink, bathe with, swim in and use for a lot of other things. An effective but one type of important filter is manufactured using stainless steel mesh. This is one type of filter that completely satisfies all your filtering requirements

The fact is that stainless steel filters come with so many great advantages to make them a perfect choice fifty you. First of all its extremely tough. They are able to work under harsh conditions, therefore can be used for a long time and require almost zero maintenance. A stainless steel material will not rust, his is another great thing about this. This attribute is what makes it an excellent choice for filters that have to last and not break down over time.

Unquestionably, one of the features to be highlighted in stainless steel filters is its durability. They can withstand extreme heat, heavy pressure and even harsh chemicals on these filters. This strength also ensures that stainless steel filters will remain in working order for many years before you start to notice any wear or tear. That trait is especially vital for both households(since households would need pure water in every way possible) and businesses, so that they may provide clean water (say like restaurants where sometimes the water would be directly used to cook food).

The Stainless steel filters are best for water justification. The Xuancheng PRODUCT can filter out pollutants from the water such as dirt, sand, among others. This process make water potable and fit for every use like drinking, washing, swimming etc. The water becomes clearer, cleaner and healthier for all those that use these filters. Stainless steel filters Stainless steel water filters can also help in removing harmful chemical such as chlorine and fluoride in the water. It then removes impurities using a carbon filter and other filters to clean the water, which can make it safer for those who have sensitive skin to shower or wash their hair and even brush their teeth.

The choice of a proper stainless steel filter for your application is based on some critical aspects. Mesh SizeOne big factor is the mesh size. This window screen is depending on the mesh, how small particles and dirt will this screen be able to filter from the air. If the net is smallest, the Finest filtration Particles it catches but it may required cleaning more often. A smaller mesh size catches smaller particles, while the opposite is true for a larger mesh size. Also important is the shape of the mesh since different shapes may be better at actually trapping dirt and other debris. Type of Stainless Steel- Which grade of stainless steel is used to make the filter can play a role in strength, susceptibility to rust and price

They are also one of the earth friendliest options with stainless steel filters. Reusable and Recyclable (helps reduce waste) Xuancheng Automatic Stainless Steel Screen Belt prevent you from having to throw away paper filters which are not biodegradable and ultimately contribute to landfill. It is thus a green option for both residential as well as commercial set-ups. Stainless steel filters are also cost-effective in the long run, since you will not need to replace them as frequently as other filter materials.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the production and development of plastic extrusion filters, and has extensive technical expertise and industrial experience. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of films, sheets and other industries in addition to the filtering of chemical fiber spinning as well as other fields. The products comprise filter mesh, edging mesh, spot-welded mesh, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt wire mesh mist eliminator and more. They offer a comprehensive assortment to meet the demands of a variety of customers. The company has provided services to more than 500 famous plastic, petrochemical, and metallurgical firms around the world. Its name is well recognized and covers a wide range of markets. The company has a high technical force, high degree of specificization, complete production equipment and a complete test method. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

The company is equipped with a skilled after-sales service department, which is accessible via phone, online customer service or social media, as well as other communication methods, can quickly provide customers with technical support, consultation on products as well as cargo tracking along with troubleshooting services. After the goods are sold, regular and in-depth communication with the client is made to know the use they are currently making of their filters, as well as the needs of the future and their expectations. In gathering feedback from customers as well as issues encountered in the service after sales department, it can respond rapidly and give timely treatment or respond. Moreover, the feedback is also fed back to production and design departments to enhance the quality of products and services. The expert team examines the root of the problem and provides basic solutions to minimize the chance of repeating the same problem. The two complement one another and only then can we provide our customers with the highest quality customer service. This, in turn, can increase customer satisfaction and allow the business to expand.

The extruder filter is constructed of high-quality metal material and has a precise filter pore size, which can effectively remove impurities in the polymer melt and increase the quality and purity of the product. The structure of the filter is designed to ensure a constant efficiency of filtration as the material moves through it, thus reducing the possibility of the chance of clogging. This helps to ensure that the production process is continuous. The metal filter is highly resistant to resistance to corrosion, wear as well as high temperatures. In accordance with the diverse requirements of the customers as well as the particular specifications of the extruder filters that are custom-designed can be designed to guarantee the perfect fit with existing equipment, and to provide the highest filtration effect. A high-performance filtering system can reduce the time lost to downtime caused by impurities clogging and also increases the efficiency.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy