Are you interested in something a little tougher and more functional? If yes, then you must know about Xuancheng's plain weave wire mesh! In this guide, you’ll read everything you need to know about the properties and benefits of this wonderful material and a little help on how to utilize it best. You will see why this is such a unique material and how it can be applied in many different ways.

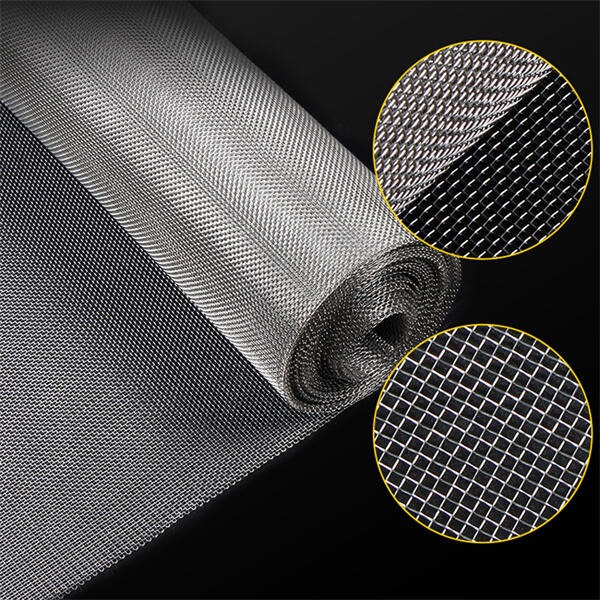

The plain weave stainless steel wire mesh is a coil-worthy piece that comes from the woven metal strands. It means it is woven together with thin layers of metal, so it is very strong. It is good enough to withstand extremely high heat with extreme weather patterns, making it an excellent choice for many applications. You know, if you need something that can take the heat, or if you need something that can remain sturdy in the harshest of conditions — this wire mesh is the way to go.

The unique properties of plain weave stainless steel wire mesh make it suitable for many types of applications. First, it doesn’t rust so it can remain looking pretty good and working well even when it gets wet. Nor does it corrode, which means it won’t Get damaged by chemicals. Which makes it an intelligent selection for areas where it may be in contact with drinking water or robust materials. Another great thing about this mesh is it's very malleable which means you can achieve various shapes. Metal mesh that can be used to create window screens or nets to prevent insects from entering their homes It is also used to strengthen buildings or as a filter in factories to purify liquids and air.

Another paralel feature of plain weave stainless steel wire mesh is material intensity. Designed to be durable, is capable of withstanding high heat without deteriorating. That is really beneficial in hot conditions like kitchens or factories that contain amazing climes. As well, it is a great product for places where it is wet or humid, because it does not rust or corrode easily. So, you can use it in moisture-ridden areas without the fear of damage. It is also chemical resistant, so if you spill something on it, it is easy to wipe up. All of these amazing characteristics combine to make it a versatile material that has a broad range of applications, from construction to food manufacturing.

Different industries use plain weave stainless steel wire mesh, and it has a diverse application. It is often used for structural purposes, for instance in the construction of buildings, which is extremely important for safety. It is also used in creating electronic components in which it serves as an insulator or a base for the parts. It is also used in the food industry to filter food and liquids to keep them free and safe to consume. And finally, in medicine it is used to give support to tissues and organs during surgery on the operating table, so that the doctors can do their work in a more efficient manner.

Stainless Steel Wire Mesh Safety Tips You Should Know Be sure to always wear gloves and safety goggles when handling this to avoid injuries. If you want to use a metal mesh for your project, measuring and cutting it to the right size and shape is also extremely important! This approach makes it possible to control that everything is tied well. Finally, utilize correct tools to assemble the material as pliers or snips to avoid damage while working.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the production and development of plastic extrusion filters, and has extensive technical expertise and industrial experience. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of films, sheets and other industries in addition to the filtering of chemical fiber spinning as well as other fields. The products comprise filter mesh, edging mesh, spot-welded mesh, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt wire mesh mist eliminator and more. They offer a comprehensive assortment to meet the demands of a variety of customers. The company has provided services to more than 500 famous plastic, petrochemical, and metallurgical firms around the world. Its name is well recognized and covers a wide range of markets. The company has a high technical force, high degree of specificization, complete production equipment and a complete test method. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

A skilled team of after-sales services is on hand to provide complete technical and service support. This can be done by calling the company's number, online customer service and social media. When the products are purchased, regular communication with the buyer is conducted to gain an understanding of the usage of their filters, as well as the future requirements and expectations. The after-sales team can address customer concerns and feedback quickly by collecting the details. Additionally, feedback from customers is also passed back to the product design and production departments in order to improve the quality of products and services. The experienced team examines the root of the problem and provides key solutions to decrease the frequency of this issue. Only when the two complement each other can we give customers an exceptional after-sales customer experience. This enhances customer loyalty and aids in the long-term growth of the enterprise.

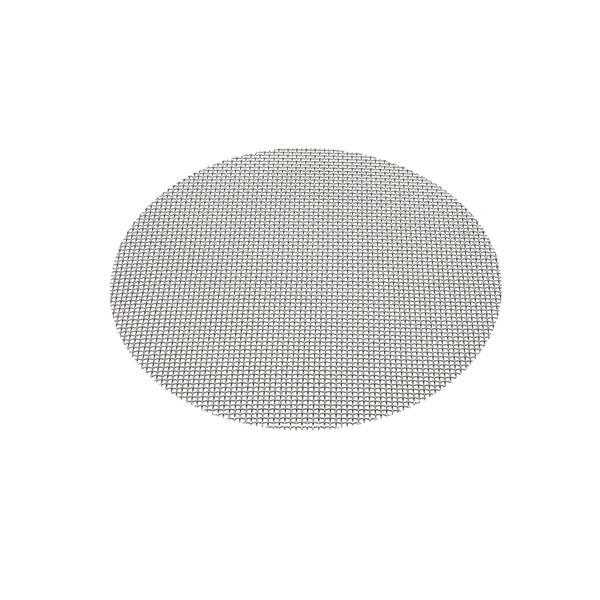

The extruder filter is constructed of high-quality metal material and has a precise filter pore size, which can effectively remove impurities in the polymer melt and increase the quality and purity of the product. The structure of the filter is designed to ensure a constant efficiency of filtration as the material moves through it, thus reducing the possibility of the chance of clogging. This helps to ensure that the production process is continuous. The metal filter is highly resistant to resistance to corrosion, wear as well as high temperatures. In accordance with the diverse requirements of the customers as well as the particular specifications of the extruder filters that are custom-designed can be designed to guarantee the perfect fit with existing equipment, and to provide the highest filtration effect. A high-performance filtering system can reduce the time lost to downtime caused by impurities clogging and also increases the efficiency.

The customized service includes the choice of filter pore size materials, shapes, and other factors as well as the ability to create custom filters that meet the specific requirements of each customer and the specifications of the extruder. By utilizing customized services, the structure and material, the filtration accuracy and other aspects of the filter can be optimized so as to enhance its filtration efficiency and service life. The process is designed according to the specific requirements of the customers, while avoiding unnecessary waste in order to save customers money. Based on the particular requirements and requirements of the customers, considering the special demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Select materials with the same properties, for example stainless steel, galvanized iron and more. Create a filter design that is appropriate for the installation and usage conditions of your client.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy