هل كنت تعلم عن شبكة مرشح الكربون هذا جهاز فريد يحافظ على الهواء والماء الذي تستخدمه نقيًا، ويقضي على الأشياء الضارة المسؤولة عن مشاكل صحية لديك. وهذا مهم لأن هذه الشاشات تساعد في ضمان جودة هواءنا ومياهنا. تابع القراءة لمعرفة كيفية عملها، والفائدة التي تقدمها، وكيف يمكنك الحصول عليها في منزلك للاستمتاع بهواء وماء أنقى.

تُصَدِّر شاشات фильتر الكربون المواد الكيميائية الضارة، والطين، وغيرها من الملوثات في الهواء والماء. تحقق ذلك باستخدام كتل كربونية صغيرة ملفوفة بثقوب دقيقة. يقول: إن هذه الثقوب صغيرة ولكنها قوية. عندما يتدفق الهواء أو الماء عبر الكتل الكربونية، تتراكم المواد القذرة داخل الكربون، مما يمنعها من الخروج مع الهواء أو الماء النظيف. بهذه الطريقة، ستتمكن من التنفس بسهولة أكبر وشرب ماء أكثر أمانًا.

إذا كنت تقدر الهواء النقي والماء في منزلك، فهناك العديد من الفوائد لاستخدام شاشات مرشح الكربون. أولاً، إنها تزيل المواد الضارة من الهواء التي قد تجعلك مريضًا. على سبيل المثال، يمكنها حل مشاكل مثل الربو أو الحساسية، والتي قد تُثار بسبب الغبار، الدخان، أو الملوثات الجوية الأخرى. الأكسجين هو مورد حيوي ويمكن تنقيته باستخدام شاشة مرشح الكربون، مما يتيح لك التنفس هواء أنقى والشعور بالتجدد يوميًا.

ثانيًا، يمكن لشاشات مرشح الكربون تصفية وتحسين جودة مياه الشرب لديك. يمكنها تقليل المواد الكيميائية والملوثات الضارة، مما يضمن أن تكون مياهك آمنة وصحية. توفر مرشحات الكربون ماء نقيًا وواضحًا كالبلور وذو طعم رائع. لذلك، هذا مهم بشكل خاص للأسر، لأننا جميعًا بحاجة إلى شرب كمية كافية من الماء يوميًا.

بالطبع، إذا كنت مهتمًا بتركيب شاشة مرشح فحمي في منزلك، فمن المفيد أن تفهم شيئًا قليلاً عن العملية وأين يجب وضع شاشات المرشح الفحمي. ابدأ بتحديد الأماكن في منزلك حيث قد تكون الهواء والماء نسبيًا غير نظيف. بالنسبة لمرشحات الهواء، يمكنك تركيبها في أنظمة التكييف أو التدفئة. يمكن تركيب مرشح المياه في مكان تحت حوض المطبخ أو ربطه بالصنبور بدلاً من ذلك.

بإعتناء صحيح بشاشات المرشحات الفحمية، فهي قادرة على التقاط الروائح الكريهة، والأوساخ والغاز الذي يمكن أن يؤدي إلى انخفاض الجودة. ومع ذلك، تذكر أن شاشات المرشحات الفحمية يجب استبدالها تقريبًا كل ثلاثة أشهر. هذا يسمح لها بالتأكد من أن الأمور تعمل بشكل صحيح وأنها لا تزال تحافظ على نقاء هواءك ومياهك.

مقارنة بأنواع أخرى من الفلاتر، فإن شاشات فلاتر الكربون هي خيار ممتاز من حيث الصداقة للبيئة. فهي لا تنتج أي تلوث أثناء التنظيف، وهو أمر أساسي لحفظ صحة الكوكب. تعتمد بعض الفلاتر على الكهرباء لأداء وظيفتها، لكن فلاتر الكربون لا تحتاج إلى أي طاقة، مما يساعد في توفير الطاقة.

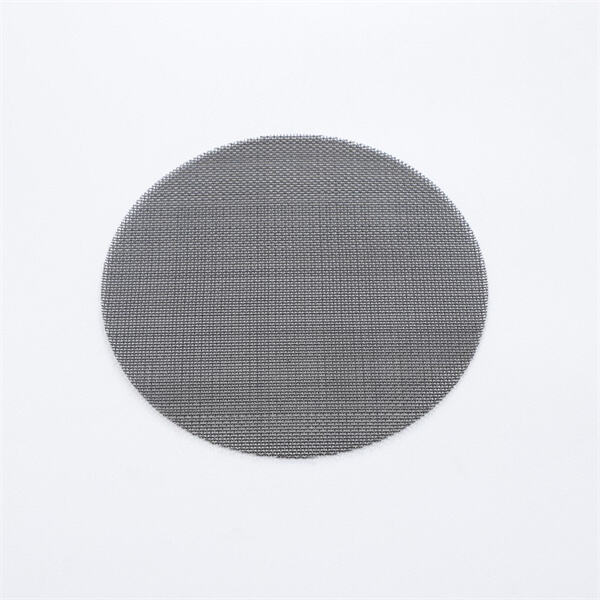

يُصنع مرشح الخلاط من معدن عالي الجودة ويتميز بحجم صغير جدًا لمسام المرشح، مما يزيل الشوائب من خليط البوليمر بكفاءة ويعزز نقاء وجودة البوليمر. تم تصميم هيكل المرشح ليحافظ على كفاءة عالية في الترشيح أثناء مرور المادة من خلاله، مما يقلل من احتمالية الانسداد. وهذا يحسن استمرارية الإنتاج. يتمتع المرشح المصنوع من المعدن بمقاومة ممتازة للتآكل، والارتداء، ودرجات الحرارة العالية. وفقًا لمتطلبات العملاء الخاصة ومعلمات الخلاط المحدد، تتوفر حلول مرشح مخصصة لضمان توافق كامل مع المعدات الموجودة وتوفير أفضل تأثير ترشيح. يؤدي الترشيح الفعال إلى تقليل الوقت الضائع بسبب انسداد المواد غير النقية وتحسين الإنتاجية.

شركة Yangzhou Xuancheng Filter Screen Co., Ltd., وهي شركة متخصصة في تصنيع شاشات البثق، مكرسة لتصميم وإنتاج مرشحات البثق البلاستيكية منذ فترة طويلة. لقد جمعوا كمية كبيرة من الخبرة الفنية والمعرفة في هذا المجال. يتم استخدامها على نطاق واسع في مجالات إعادة تدوير الحبيبات المعدلة والبلاستيكية، وبثق الأفلام والألواح وغيرها، بالإضافة إلى فلاتر خيوط الألياف الكيميائية. تتضمن منتجاتهم مرشحات، شبكات حدودية، شبكات اللحام النقطي، أحزمة شبكة الفولاذ المقاوم للصدأ ذات التبديل التلقائي، شبكات التعزيز، ناقلة الحركة، ومرشحات الضباب الشبكي، وما إلى ذلك. توفر الشركة مجموعة شاملة لتلبية احتياجات مجموعة متنوعة من العملاء. وقد خدمت أكثر من 500 شركة معروفة تعمل في مجالات البلاستيك والبتروكيماويات والمعادن حول العالم. العلامة التجارية معروفة جيدًا ويمكنها تغطية مجموعة متنوعة من الأسواق. تمتلك الشركة قوة تقنية كبيرة وتتمتع بمعدات إنتاج متخصصة، بالإضافة إلى عملية اختبار شاملة. وقد حصلت الشركة على شهادة ISO9001:2015 لضمان منتج مستقر وموثوق.

تشمل الخدمات المخصصة اختيار مادة الفلتر، وحجم وشكل المسامات، بالإضافة إلى جوانب أخرى. يمكنها أيضًا توفير فلاتر مخصصة وفقًا لمتطلبات ومواصفات العملاء لجهاز التشكيل بالحقن. تسمح الخدمات المخصصة بتحسين المعلمات الخاصة بالتنقية مثل مادة البنية، ودقة التنقية وغيرها. يمكن أن يحسن ذلك كفاءة تنقية الفلتر ويطيل من عمره الافتراضي. يتم الإنتاج وفقًا لمتطلبات العميل المحددة، ويتجنب الهدر الزائد لتوفير المال للعملاء. بناءً على الاحتياجات والتطبيقات المحددة للعملاء، مع أخذ المتطلبات الخاصة مثل مقاومة التآكل وكذلك مقاومة درجات الحرارة العالية والاحتكاك وما إلى ذلك في الاعتبار. اختر المواد التي تمتلك الخصائص المناسبة مثل الحديد المغلفن، والفولاذ المقاوم للصدأ وما إلى ذلك. قم بتصميم فلتر مناسب لظروف التركيب والتشغيل الخاصة بعميلك.

يوجد فريق ماهر من خدمات ما بعد البيع جاهز لتقديم الدعم الفني والخدمي الكامل. يمكن القيام بذلك عن طريق الاتصال برقم الشركة، أو خدمة العملاء عبر الإنترنت ووسائل التواصل الاجتماعي. عند شراء المنتجات، يتم إجراء اتصال منتظم مع المشتري لفهم استخدامهم للفلاتر الخاصة بهم، وكذلك المتطلبات والتوقعات المستقبلية. يمكن لفريق ما بعد البيع التعامل بسرعة مع مخاوف وتقييمات العملاء من خلال جمع التفاصيل. بالإضافة إلى ذلك، يتم نقل تقييمات العملاء أيضًا إلى أقسام تصميم وإنتاج المنتجات من أجل تحسين جودة المنتجات والخدمات. يقوم الفريق ذو الخبرة بفحص جذور المشكلة ويقدم حلولًا أساسية لتقليل تكرار هذه المشكلة. فقط عندما يكمل كل منهما الآخر يمكننا تقديم تجربة استثنائية للعملاء فيما يتعلق بخدمة ما بعد البيع. هذا يعزز ولاء العملاء ويساعد في النمو طويل الأمد للشركة.

جميع الحقوق محفوظة © شركة يانغتشو شوانشينغ لصناعة الشاشات المرشحة المحدودة - سياسة الخصوصية