عند تنقية سائل، من الضروري إزالة الأوساخ والقطع الصغيرة التي قد تكون موجودة في السائل. وهنا تأتي أهمية المرشحات. فكما في شبكة الصرف الصحي، تقوم المرشحات باعتراض القطع غير المرغوب فيها وتسمح بمرور السائل النظيف. الآن هناك العديد من أنواع المرشحات، بما في ذلك نوع جدير بالذكر وهو مرشح 120 مESH.

حسنًا، إذن الملوثات هي المقصودة. نحن نتحدث عن الملوثات كالأشياء التي لا نريدها في سوائلنا أو غازاتنا. قد تكون هذه الملوثات ترابًا، جزيئات غبار، جراثيم مجهرية، أو أي شيء آخر يمكن أن يسبب لنا المرض. في بعض الأحيان، علينا أن نتأكد تمامًا من نظافة السوائل والغازات بشكل تام، على سبيل المثال عند استخدامها في مجالات حيوية مثل الطب أو صناعة الأغذية. ومن الواضح أننا بحاجة إلى مرشحات تحمينا من مثل هذه المواقف.

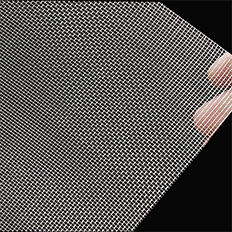

ربما تتساءل الآن، "ألم تلتقط كل المرشحات الجسيمات الصغيرة؟" هذا سؤال جيد! في الواقع، من الصحيح أن العديد من المرشحات يمكنها التقاط المواد الصغيرة، ولكن مرشحات الشبكة ذات العدد 120 رائعة في ذلك!! لقد صُمّمت بدقة بحيث يمكنها التقاط هذه الجسيمات المجهرية التي تمر عبر المرشحات الأكبر دون أن تُلتقط، وهذا الأمر مهم للغاية عندما يتعلق الأمر بالسوائل والغازات الحساسة مثل المواد الكيميائية. كل ما يتطلبه الأمر هو مرور جسيم صغير جدًا ليتسبب في مشكلة.

مثلما إذا كنت تقوم ببناء شيء رائع، لنفترض سيارة. من أجل عمل السيارة كما هو مخطط لها، يجب أن تكون السوائل والغازات نظيفة وكذلك الجاذبية. إذن ماذا يعني النظافة بالنسبة لهذه السوائل والغازات؟ هنا تأتي أهمية ضبط الجودة. باستخدام فلاتر الشبكة 120، يمكننا التأكد من أن السوائل والغازات المستخدمة نظيفة جداً. هذا يساعد السيارة على العمل والتشغيل بشكل جيد وآمن.

أخيرًا، تتميز فلاتر الشبكة 120 بالمرونة والقوة العالية. حيث تُستخدم في صناديق مهمة جدًا وتُطبق في مجموعة متنوعة من الصناعات مثل الطبية، وصناعة السيارات، وإنتاج الأغذية. فهي سهلة الاستخدام ويمكن تركيبها في أي مكان تقريبًا وفي جميع أنواع الآلات والمعدات. بالإضافة إلى ذلك، فهي قوية جدًا! على الرغم من أنها مصنوعة من فتحات منفصلة، إلا أنها متينة للغاية ويمكنها تحمل القوة الكبيرة دون أن تنكسر. لذلك يمكن استخدامها في معظم الحالات دون أي مشاكل.

تتكون الخدمة المخصصة من اختيار حجم فتحة الفلتر بالإضافة إلى الشكل، المادة والجوانب الأخرى وستوفر فلاتر مخصصة لتلبية المتطلبات الخاصة لكل عميل والمحددات الخاصة للمضغوط. الخدمات المخصصة تمكن من تعزيز معلمات الترشيح مثل البنية، المادة، دقة الترشيح وغيرها الكثير. هذا يحسن كفاءة ترشيح الفلتر وعمره الافتراضي. يتم إجراء عملية الإنتاج وفقًا لاحتياجات العملاء، مع تجنب الهدر غير الضروري لحفظ أموال العملاء. بناءً على الاحتياجات والأوضاع التطبيقية الخاصة للعملاء، مع مراعاة المتطلبات الخاصة مثل مقاومة التآكل وكذلك مقاومة درجات الحرارة العالية، مقاومة الاحتكاك وما إلى ذلك. اختر مواد ذات خصائص مماثلة، على سبيل المثال الحديد المغلفن، الفولاذ المقاوم للصدأ وما إلى ذلك. تأكد من أن تصميم الفلتر الخاص بك يكون مناسبًا لظروف التركيب والاستخدام الخاصة بعميلك.

يُصنع الفلتر في المُذيب من معدن ذي جودة عالية، وله مسام صغيرة للفiltration. هذا يسمح له بإزالة الشوائب وتحسين نقاء وجودة البوليمر. تم تصميم هيكل الفلتر لضمان استقرار تدفق المادة أثناء الترشيح أثناء مرورها، مما يقلل من الانسداد ويعزز استمرارية الإنتاج. يتمتع الفلتر المصنوع من المعدن بمقاومة ممتازة للتآكل، والارتداء، والعوامل الحرارية العالية. يمكن العثور على منتجات فلاتر مخصصة لتلبية متطلبات العملاء المختلفين وللتوفيق مع المعدات. يقلل نظام ترشيح عالي الأداء من حالات التأخير الناتجة عن انسداد الشوائب ويزيد من الإنتاجية.

تتمتع الشركة بفريق خدمة ما بعد البيع المتمرس، حيث يمكنها من خلال الهاتف والخدمة العملاء عبر الإنترنت فضلاً عن وسائل التواصل الاجتماعي وغيرها من طرق الاتصال، تقديم الدعم الفني والاستشارات المتعلقة بالمنتجات وتتبع الشحنات وإصلاح الأعطال بين الخدمات الأخرى بشكل سريع للعملاء. ستقوم الشركة بالتواصل مع العملاء بشكل دوري بعد الشراء لمعرفة استخدامهم الحالي للفلاتر والتوقعات المستقبلية. يستطيع فريق خدمة ما بعد البيع التعامل بسرعة مع شكاوى العملاء والملاحظات من خلال جمع البيانات. بالإضافة إلى ذلك، يتم إرسال التغذية الراجعة أيضًا إلى أقسام تصميم المنتجات والإنتاج لتحسين جودة المنتجات والخدمات. يقوم الفريق ذو الخبرة بتحليل السبب الجذري للمشكلة ويقدم حلول أساسية لتقليل فرصة تكرار نفس المشكلة. عندما يكون هناك تناغم بين الاثنين، سنتمكن من تقديم تجربة استثنائية للعملاء في خدمة ما بعد البيع. وهذا يعزز ولاء العملاء ويدفع نحو تطوير مستدام للشركة على المدى الطويل.

شركة يانغتشو شوانشينج فلتر سكرين المحدودة، وهي الشركة المصنعة لشاشات البثق، قد خصصت نفسها لتصميم وتصنيع مرشحات البثق البلاستيكية لسنوات عديدة. لقد تراكم لديها كمية كبيرة من الخبرة الفنية والتجربة في هذا المجال. يتم استخدام المرشحات بشكل واسع في إعادة تدوير حبيبات البلاستيك المعدلة، وإنتاج الأفلام والألواح البلاستيكية وغيرها من العمليات الصناعية، بالإضافة إلى ترشيح دوامة الألياف الكيميائية وغيرها من المجالات. هناك مجموعة متنوعة من المنتجات، بما في ذلك المرشحات، الشباك الحدودية، الشباك اللحام بالنقاط، أحزمة الشبك الفولاذي المقاوم للصدأ، الشباك المدعومة، أحزمة النقل، مزيلات الضباب وغير ذلك. توفر مجموعة واسعة لتلبية احتياجات العملاء المختلفة. وقد قدمت خدماتها لأكثر من 500 شركة تصنيع معروفة في مجالات البلاستيك والبتروكيماويات والمعادن حول العالم، مما يوفر تغطية سوقية واسعة وتأثيرًا قويًا للعلامة التجارية. تمتلك الشركة قوة تقنية عالية، درجة عالية من التخصص، معدات إنتاج كاملة وعملية اختبار واسعة. كما أنها قد حصلت على شهادة نظام إدارة الجودة ISO9001:2015 لضمان جودة المنتج المستقرة والموثوقة.

جميع الحقوق محفوظة © شركة يانغتشو شوانشينغ لصناعة الشاشات المرشحة المحدودة - سياسة الخصوصية