Did you know about the carbon filter mesh? This is a unique device that maintains the air and water you use at clean hands, eliminating harmful exact things that responsible for your health issues. This is critical because those screens help ensure the quality of our air and our water. Read on to find out how they work, what benefits they offer and how you can get them into your own home to enjoy cleaner air and water.

Carbon filter screens trap harmful chemicals, dirt, and other pollutants in the air and water. They accomplish this by employing small carbon blocks wound with tiny holes. These holes are tiny but mighty, he says. As air or water flows through the carbon blocks, the dirty stuff gets stuck in the carbon, which prevents it from coming out along with the clean air or water. That way, you’ll be able to breathe a little easier and drink a little safer water.

If you value clean air and water in your home, there are a plethora of merits to using carbon filter screens. First, they remove harmful stuff from the air that may make you sick. For instance, they can resolve issues such as asthma or allergies, which may be triggered by dust, smoke, or other airborne pollutants. Oxygen is a vital resource, and can be purified with a carbon filter screen that allows you to breathecleaner air and be more rejuvenated every day.

Second, carbon filter screens can filter and may improve the quality of your drinking water. They can reduce harmful chemicals and contaminants, ensuring that your water is safe and healthy. Carbon filters provide you with pure, crystal clear water that tastes great. So, this is particularly important for families, because we all need to drink sufficient water per day.

Of course, if you are interested in placing a carbon filter screen in your home, it helps to understand a little bit about the process and where to place carbon filter screens. Start by identifying places in your home where the air and water may be relatively dirty. For air filters, you can set them in the air conditioning or heating systems. A water filter can be installed in a space under the kitchen sink or attached to your faucet instead.

Properly cuidando the screen of the carbon filters they are capable of capturing bad odors, dirt and gas that can lead to low quality. Keep in mind, though, that carbon filter screens should be replaced approximately every three months. This allows them to make sure those things are working correctly and that they’re still keeping your air and water clean.

Compared to some other types of filters, Carbon filter screens are an excellent choice from an environmentally friendly perspective. They don't produce any pollution when cleaning which is essential for keeping the Planet healthy. Some filters rely on electricity to perform their job, but carbon filters don’t require any power, helping save energy.

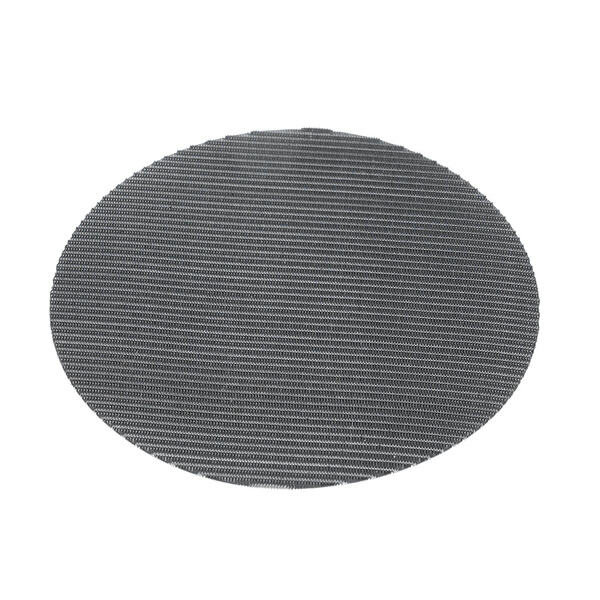

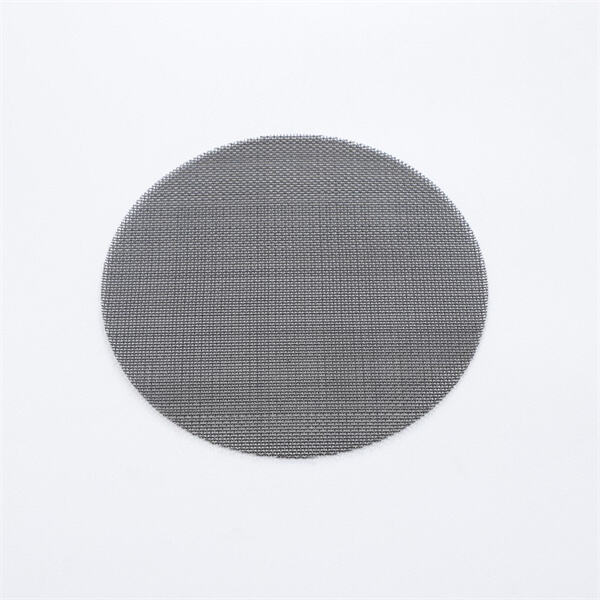

The extruder filter is made of high-quality metal and features a very fine size of the filter pore, which effectively removes impurities from the polymer melt and enhance the purity and quality of the polymer. The filter's structure is designed to maintain a high efficiency in filtration while the material moves through it, reducing the possibility of clogging. This improves production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. As per the specific requirements of clients and the exact specifications of the extruder specific filter solutions are available to ensure a perfect match with existing equipment and provide the most effective filtration effect. Filtration efficiency that is efficient reduces the amount of time that is lost due to the clogging of impure materials and improves productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd., an extruder screen manufacturer is devoted to the design and manufacture of plastic extrusion filter for a long time. They have amassed vast amounts of technical expertise and know-how in the field. They are extensively used in the fields of plastic modified granulations recycling granulations, extrusions made of films and sheets and many more in addition to filters for spinning chemical fibers. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor belt, wire mesh mist eliminator, and so on. They offer a comprehensive collection to meet the needs of a variety of customers. The company has served over 500 well-known plastic, petrochemical and metallurgical companies around the world. The brand is well known and it is able to cover a variety of markets. The company has strong technical strength and possesses specialized production equipment, as well with a comprehensive testing process. The company has been accredited to ISO9001:2015 to ensure a stable and reliable product.

Customized services include the selection of the filter material, pore size and shape, as well as other aspects. They can also provide customized filters according to customer requirements and specifications for the extruder. The customized services allow the optimization of parameters for filtering such as structure material, filtration accuracy and more. This can improve the efficiency of filter filtration and longevity. The production is performed according to the specific requirements of the customer, and avoids excessive waste, in order to save customers money. According to the specific needs and applications of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Choose the materials that have corresponding properties, such as galvanized iron, stainless steel, etc. Create a filter design that is appropriate for the installation and operating conditions of your client.

A skilled team of after-sales services is on hand to provide complete technical and service support. This can be done by calling the company's number, online customer service and social media. When the products are purchased, regular communication with the buyer is conducted to gain an understanding of the usage of their filters, as well as the future requirements and expectations. The after-sales team can address customer concerns and feedback quickly by collecting the details. Additionally, feedback from customers is also passed back to the product design and production departments in order to improve the quality of products and services. The experienced team examines the root of the problem and provides key solutions to decrease the frequency of this issue. Only when the two complement each other can we give customers an exceptional after-sales customer experience. This enhances customer loyalty and aids in the long-term growth of the enterprise.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy