هل أنت مهتم بشيء أكثر صلابة ووظيفية؟ إذا كانت الإجابة نعم، فعليك أن تعرف عن مدينة Xuancheng شبكة سلكية نسج عادي ! في هذا الدليل، ستقرا عن كل ما تحتاج لمعرفته حول خصائص ومزايا هذه المادة الرائعة وبعض المساعدة حول كيفية استخدامها بأفضل طريقة. ستكتشف لماذا تعتبر هذه المادة فريدة من نوعها وكيف يمكن تطبيقها بطرق مختلفة.

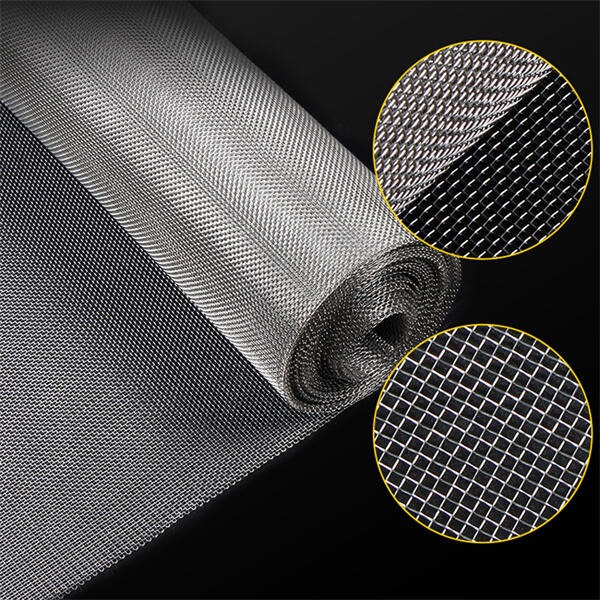

الشبكة المعدنية المنسوجة ذات النسج البسيط هي قطعة تستحق التخزين في لفائف، وتأتي من خيوط معدنية منسوجة. يعني ذلك أنها منسوجة معًا باستخدام طبقات رقيقة من المعدن، لذلك فهي قوية جدًا. وهي كافية لتحمل الحرارة العالية جدًا والأنماط الجوية القاسية، مما يجعلها خيارًا ممتازًا للكثير من التطبيقات. تعرف، إذا كنت بحاجة إلى شيء يمكنه تحمل الحرارة، أو إذا كنت بحاجة إلى شيء يمكن أن يبقى ثابتًا في أصعب الظروف — فإن هذه الشبكة السلكية هي الخيار الأفضل.

تجعل الخصائص الفريدة للنسيج المستوِي من شبك السلك الفولاذي المقاوم للصدأ مناسبًا لعدد كبير من التطبيقات. أولاً، لا يصدأ، لذلك يمكن أن يبدو جيدًا ويستمر في العمل بشكل جيد حتى عندما يبتل. كما أنه لا يتأكل، مما يعني أنه لن يتضرر بسبب المواد الكيميائية. وهذا يجعله اختيارًا ذكيًا للمناطق التي قد يكون فيها اتصال مع المياه الصالحة للشرب أو المواد القوية. شيء آخر رائع حول هذا الشبك هو أنه مرناً جدًا، مما يعني أنك تستطيع الحصول على أشكال مختلفة. يمكن استخدام الشبك المعدني لصنع شاشات النوافذ أو شبكات لمنع دخول الحشرات إلى المنازل. كما يستخدم أيضًا لتقوية المباني أو كمرشح في المصانع لتنقية السوائل والهواء.

ميزة أخرى متوازية لشبكة الأسلاك الفولاذية المقاومة للصدأ ذات النسج البسيط هي كثافة المادة. مصممة لتكون قوية، ويمكنها تحمل الحرارة العالية دون التدهور. وهذا مفيد جدًا في الظروف الحارة مثل المطابخ أو المصانع التي تحتوي على مناخات شديدة. كما أنها منتج رائع للأماكن الرطبة أو الرطبة، لأنها لا تصدأ أو تتآكل بسهولة. لذلك، يمكنك استخدامها في المناطق الرطبة دون خوف من التلف. كما أنها مقاومة للكيميائيات، لذلك إذا أسكنت شيئًا عليها، فمن السهل مسحه. جميع هذه الخصائص الرائعة تجمع لجعلها مادة متعددة الاستخدامات لديها نطاق واسع من التطبيقات، من البناء إلى تصنيع الأغذية.

تستخدم الصناعات المختلفة الشبكة المعدنية المنسوجة بالطريقة البسيطة المصنوعة من الفولاذ المقاوم للصدأ، ولها تطبيقات متنوعة. غالباً ما تُستخدم للأغراض الهيكلية، على سبيل المثال في بناء المباني، وهو أمر بالغ الأهمية لضمان السلامة. كما تُستخدم أيضاً في تصنيع المكونات الإلكترونية حيث تعمل كمعزول أو كقاعدة للمكونات. بالإضافة إلى ذلك، تُستخدم في صناعة الأغذية لتنقية الأطعمة والسوائل للحفاظ عليها نظيفة وآمنة للاستهلاك. وأخيراً، في المجال الطبي تُستخدم لتوفير الدعم للأنسجة والأعضاء أثناء الجراحة على طاولة العمليات، مما يمكّن الأطباء من أداء عملهم بطريقة أكثر كفاءة.

نصائح السلامة لشبكة الأسلاك الفولاذية التي يجب أن تعرفها: تأكد دائمًا من ارتداء القفازات ونظارات السلامة عند التعامل مع هذه المادة لتجنب الإصابات. إذا كنت تريد استخدام شبكة معدنية لمشروعك، فإن قياسها وقطعها إلى الحجم والشكل المناسبين مهم للغاية أيضًا! هذا النهج يجعل من الممكن التحكم في أن كل شيء مربوط بشكل جيد. وأخيرًا، استخدم الأدوات الصحيحة لتجميع المادة مثل الملقط أو المقص لتجنب التلف أثناء العمل.

شركة Yangzhou Xuancheng Filter Screen Co., Ltd. هي شركة تصنيع ذات خبرة في إنتاج فلاتر المُضغّات، وقد اهتمت لفترة طويلة بإنتاج وتطوير فلاتر تشكيل البلاستيك، ولديها خبرة تقنية وصناعية واسعة. يتم استخدام هذه الفلاتر بشكل واسع في تشكيل البلاستيك وإعادة تدوير الحبيبات، وتصنيع الأفلام والألواح وغيرها من الصناعات، بالإضافة إلى تصفيح الألياف الكيميائية وغيرها من المجالات. تشمل المنتجات شبكة الترشيح، شبكة الحواف، شبكة اللحام بالنقاط، الشريط الفولاذي المقاوم للصدأ مع شبكة تعزيزية قابلة للتبديل تلقائيًا، الشريط الناقل، شبكة سلكية لإزالة الضباب وغير ذلك الكثير. توفر الشركة مجموعة شاملة لتلبية احتياجات العملاء المختلفين. قدّمت الشركة خدماتها لأكثر من 500 شركة معروفة تعمل في مجالات البلاستيك والبتروكيماويات والمعادن حول العالم. يُعرف اسم الشركة جيدًا ويغطي نطاقًا واسعًا من الأسواق. تمتلك الشركة قوة تقنية عالية، درجة عالية من التخصص، معدات إنتاج كاملة وطرق اختبار شاملة. حصلت الشركة على شهادة ISO9001:2015 لضمان استقرار وموثوقية منتجاتها.

يوجد فريق ماهر من خدمات ما بعد البيع جاهز لتقديم الدعم الفني والخدمي الكامل. يمكن القيام بذلك عن طريق الاتصال برقم الشركة، أو خدمة العملاء عبر الإنترنت ووسائل التواصل الاجتماعي. عند شراء المنتجات، يتم إجراء اتصال منتظم مع المشتري لفهم استخدامهم للفلاتر الخاصة بهم، وكذلك المتطلبات والتوقعات المستقبلية. يمكن لفريق ما بعد البيع التعامل بسرعة مع مخاوف وتقييمات العملاء من خلال جمع التفاصيل. بالإضافة إلى ذلك، يتم نقل تقييمات العملاء أيضًا إلى أقسام تصميم وإنتاج المنتجات من أجل تحسين جودة المنتجات والخدمات. يقوم الفريق ذو الخبرة بفحص جذور المشكلة ويقدم حلولًا أساسية لتقليل تكرار هذه المشكلة. فقط عندما يكمل كل منهما الآخر يمكننا تقديم تجربة استثنائية للعملاء فيما يتعلق بخدمة ما بعد البيع. هذا يعزز ولاء العملاء ويساعد في النمو طويل الأمد للشركة.

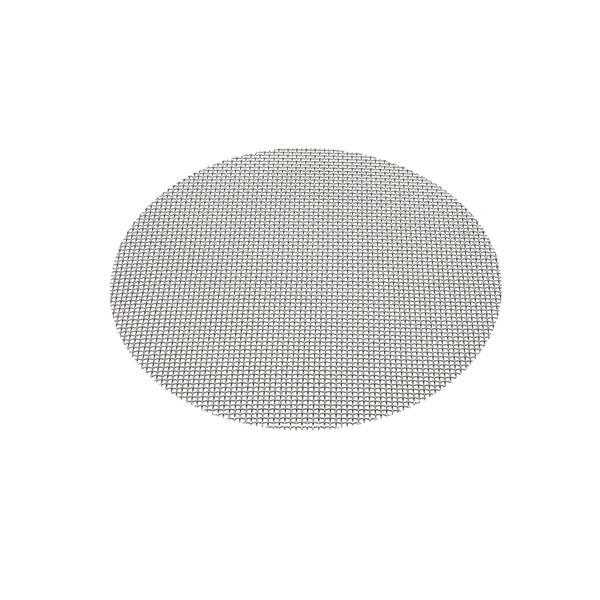

يُصنع مرشح الخلاط من مادة معدنية عالية الجودة ولديه حجم فتحات دقيقة بدقة عالية، مما يمكنه من إزالة الشوائب في خليط البوليمر بفعالية وزيادة جودة ونقاء المنتج. تم تصميم هيكل المرشح لضمان كفاءة ترشيح ثابتة أثناء مرور المادة من خلاله، مما يقلل من احتمالية الانسداد. هذا يساعد في ضمان استمرارية عملية الإنتاج. المصفاة المعدنية مقاومة بشكل كبير للتآكل، والارتداء، وأيضاً درجات الحرارة العالية. وفقًا لمتطلبات العملاء المختلفة والمحددات الخاصة، يمكن تصميم مرشحات الخلاط المخصصة لتتناسب تمامًا مع المعدات الموجودة وتوفير أفضل تأثير ترشيح. نظام ترشيح عالي الأداء يمكن أن يقلل من الوقت الضائع بسبب التوقف الناتج عن انسداد الشوائب ويزيد من الكفاءة.

تتضمن الخدمة المخصصة اختيار مواد حجم مسامات الفلتر والأشكال والعوامل الأخرى، بالإضافة إلى القدرة على إنشاء فلاتر مخصصة لتلبية المتطلبات الخاصة لكل عميل ومواصفات الجهاز البلاستيكي. من خلال استخدام الخدمات المخصصة، يمكن تحسين هيكل الفلتر والمادة، ودقة الترشيح والجوانب الأخرى لتحسين كفاءة الترشيح ومدة خدمته. يتم تصميم العملية وفقًا لمتطلبات العملاء المحددة، مع تجنب الهدر غير الضروري لحفظ أموال العملاء. بناءً على المتطلبات الخاصة للعملاء، مع مراعاة الطلبات الخاصة مثل مقاومة التآكل ومقاومة درجات الحرارة العالية والمقاومة للتآكل وما إلى ذلك، يتم اختيار مواد ذات خصائص مماثلة، مثل الفولاذ المقاوم للصدأ والحديد المغلفن وغيرها. قم بتصميم فلتر مناسب لظروف التركيب والاستخدام الخاصة بعميلك.

جميع الحقوق محفوظة © شركة يانغتشو شوانشينغ لصناعة الشاشات المرشحة المحدودة - سياسة الخصوصية