There is filtering that assists in cleaning of liquids and gases. It does that by filtering the unwanted particles and other stuff out. For this purpose, the filter mesh by Xuancheng is a wonderful aid. It does a good job of keeping unwanted things out (lasts over time), and is not too expensive. This is why many businesses opt to use it for their filtration needs.

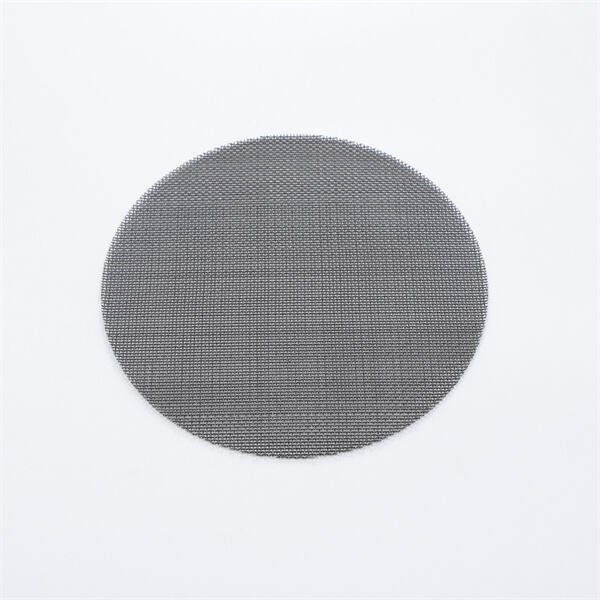

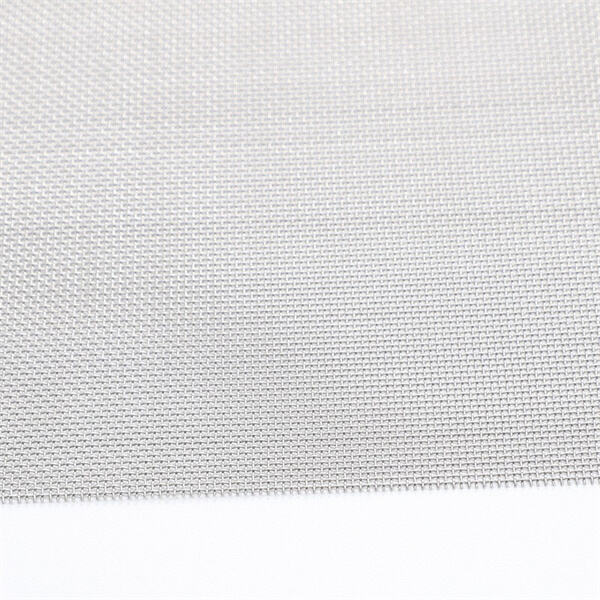

The filter mesh in Xuancheng mainly consists of high-quality and excellent-performance sort. This is specifically engineered to remove impurities from water with high proficiency. This will help to avoid using of unclean and harmful products. It is composed of high-quality, heat-resistant and pressure-tolerance materials that do not disintegrate easily.

This filter mesh is also used to liquid-solid separation. As you can imagine, this might have especially high value in places like food manufacturing plants where cleanliness and quality control are key. Such as, when it comes to the processing of things such as juice or milk, all solid particles that may stop working the item need to be gotten rid off.

Filter mesh is cost effective One of the largest benefits associated with using Xuancheng filter mesh for businesses that they can save a lot of money. This provides awesome value for performance where not very expensive. This is one of the reasons that it has been adopted so broadly across various types of manufacturing including chemical processing, oil refining and gas tendering. It is very easy for companies to trust it and get their work done without any pocket pinch.

Something only Xuancheng's filter mesh is designed to do. Constructed using wear-resistant and durable materials, you can take it out into the field with confidence. This means that it requires very low maintenance and businesses are compelled to replace the same less frequently. For businesses that have to stay operational, this is particularly crucial.

A good thing that they like with the Xuancheng Filter Mesh is a product which can be customised to accomplish certain requirements on various industries. OptionalS – It can be custom designed in different sizes, materials and forms to suit a wide range of filtration applications. It is highly compatible for cleaning water, air as well as oil.

Xuancheng filter mesh is an important reason for the use of chemical solutions to eliminate dirt impurities in industries such as chemistry, etc. In the food and beverage sector, it helps to separate solid particles and impurities from liquids such as milk, juice or beer. And for the consumer, enjoy peace of mind and take home a product that is fortified with safety features.

The company has a professional after-sales team, utilizing the telephone, online customer support along with social media and other contact methods, can efficiently provide customers with technical support, product consultation as well as cargo tracking and troubleshooting, among other services. The company will contact customers regularly after the sale to find out their current usage of filters and to anticipate their needs for the future. By collecting customer feedback and problems encountered in the service after sales department, it is able to respond quickly and offer a prompt respond. Furthermore, feedback is also passed back to product design and production departments to enhance products and services. The team of experts thoroughly investigates the cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. Both complement each other and only then can we offer our customers a high-quality customer service. This improves customer loyalty and assist the company to expand.

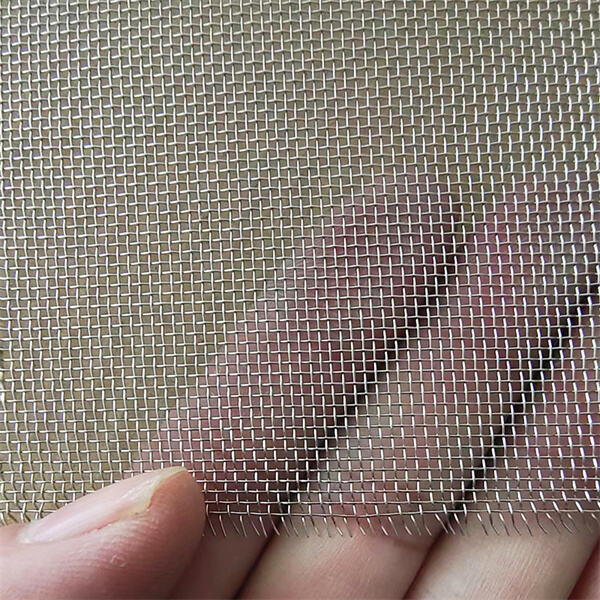

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the production and development of plastic extrusion filters, and has extensive technical expertise and industrial experience. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of films, sheets and other industries in addition to the filtering of chemical fiber spinning as well as other fields. The products comprise filter mesh, edging mesh, spot-welded mesh, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt wire mesh mist eliminator and more. They offer a comprehensive assortment to meet the demands of a variety of customers. The company has provided services to more than 500 famous plastic, petrochemical, and metallurgical firms around the world. Its name is well recognized and covers a wide range of markets. The company has a high technical force, high degree of specificization, complete production equipment and a complete test method. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy