Sick of having your pipes clog on you? The only shit is that it can be really irritating, right? You do you want liquid to flow through your pipes cleanly without any stopping/blocks? Say hi to Xuancheng stainless steel screen wire – it is your buddy filter that ensures your drink comes out as smooth as ever

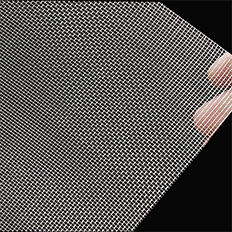

Everything works in the same way, just with a regular filter you can clog your pipes. In some cases, this can cause extensive damage that requires expensive and time-consuming maintenance. Nobody wants that. The mesh screen in Xuancheng is made of super-high-strength stainless steel. The material allows liquid to pass through as normal, while keeping solid bits and debris out. And all that can happen without you having to stress over any clogging up.

Type filters are prone to rusting and can erode. As it is, they become less potent (or stop working) when this happens. But don’t worry. And the Stainless Steel Mesh Screen of Xuancheng is really no rust. Xuancheng PRODUCT can survive through most everything and continue to perform just as well for years. Which will not require you to replace it again and again, You can rely on this protector to work.

The benefits of Xuancheng satin mesh to know before you go. The holes of mesh must be specifically designed to prevent solid fine particles, then liquid within the suspension through it. Enter the pressure regulator, and this is significant because it means that even the tiniest pieces will be trapped as well so you always get pure and secure fluid. Rest easy with the confidence that your fluids are being properly filtered.

Please note this is a shameless plug, your product can be found by visiting Xuancheng spot welding screen if you are looking for effective filtration that lasts a while, easy to clean and allows the meal liquid like us. Stop wasting time to any other place. Get yourself and enjoy the clog-free, rust-free life now. That is, every single time you put the Stainless Steel Mesh Screen from Xuancheng to work. Be able to take advantage of having a trustful filtering friend by your side.

A skilled team of after-sales services is on hand to provide complete technical and service support. This can be done by calling the company's number, online customer service and social media. When the products are purchased, regular communication with the buyer is conducted to gain an understanding of the usage of their filters, as well as the future requirements and expectations. The after-sales team can address customer concerns and feedback quickly by collecting the details. Additionally, feedback from customers is also passed back to the product design and production departments in order to improve the quality of products and services. The experienced team examines the root of the problem and provides key solutions to decrease the frequency of this issue. Only when the two complement each other can we give customers an exceptional after-sales customer experience. This enhances customer loyalty and aids in the long-term growth of the enterprise.

Yangzhou Xuancheng Filter Screen Co., Ltd. is a reputable manufacturer of extruder filter, which has been dedicated for many years to the creation and development of extrusion-based plastic filters and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other products, as well as the filtering of chemical fiber spinning and other industries. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt, wire mesh mist eliminator, etc. With a wide assortment to meet the demands of various clients. The company has offered services to more than 500 famous plastic, petrochemical and metallurgical production companies across the globe, and has a broad market coverage and strong impact on brand image. The company has a strong technological force, high degree of specialization, complete production equipment and an extensive testing process. The company has been accredited with ISO9001:2015 to ensure the stability and reliability of its product.

The extruder filter is constructed of high-quality metal and has a fine filter pore size, which effectively removes any impurities that are present in the polymer melt as well as improve the quality and purity of the final product. The filter's structure is designed to ensure a continuous filtration rate while the material flows through it, which reduces the chance of clogging. This increases the efficiency of production. Metal filters are impervious to wear, corrosion and high temperatures. In accordance with the diverse requirements of customers and the specific specifications of the extruder, specific filter solutions can be provided to ensure an ideal match with existing equipment, and to provide the highest performance in filtration. A high-performance filtration system decreases the amount of interruptions caused by the accumulation of impurities and increases productivity.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy