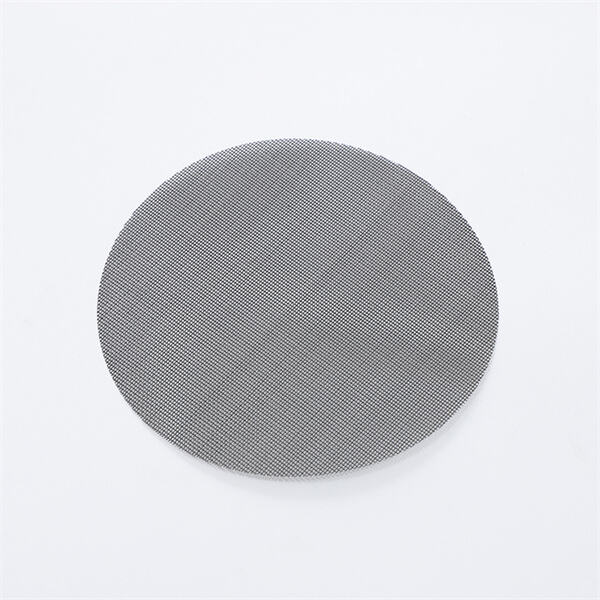

Weaving wire is an interesting and creative method which can be used for many types of wire mesh. Plain weave wire mesh is a common type of wire mesh that many people use. Welded Wire Mesh: For making this type of wire mesh; wires are intertwined or woven in mild steel. Hence, when it comes to a recognized company which specializes in manufacturing superior wire mesh gadgets, Xuancheng is the one plain enough concerning producing good quality products with the technique of this plain weave.

Plain weave metal mesh are also very important because they perform a variety of functions in building construction and is sometimes useful for certain industrial uses and household consumables. There are a few reasons this type of wire mesh is so widely used, one of which has to do with how it is constructed. Another very basic weave is an over and under pattern. This means that it should be incredibly versatile, as well as a favorite choice for many people a result.

Many of the most helpful uses for stainless filter screen are found in factories. For example, this ability can filter unwanted particles and impurities from liquids or gases. This is important in industries like the pharmaceutical manufacturing where materials must remain uncontaminated for human health. It is also utilized in the case of conveyor belts which are used for transferring items from one place to another inside the factory. They can easily transport the products back and forth. Moreover, plain weave wire mesh is widely used in separating various materials during the manufacturing process. It is an excellent option for various factory tasks because it is so strong it will be able to hold the weight and pressure that will be put on by heavy machines.

Versatile: One of the biggest reasons that plain weave wire mesh is desirable. The material used to make it includes stainless steel, copper, bronze or even brass. The qualities of every material make it ideal for various kinds of projects. It can also be used for a variety of jobs, since plain weave wire mesh is available in many different sizes and mesh counts. The fact that plain weave wire mesh holds numerous unprecedented benefits which is why a high percentage of individuals deem it as the most reliable option to fulfill their requirements.

One other advantages of a plain weave wire mesh you will notice is the basic design. The simple approach it is knitted has turns into so brief and without problems textiles to produce. This allows for quick and efficient production as it does not need complex machinery or special processes to make. What is a plus point for you that Because it recipes deliciously, it is also easily repairable on the chance of damage. This is crucial for many as large part of users who count on this software are hoping to use a reliable product for their projects.

No matter where you will be using your wire mesh, whether it is for a construction project or for a specific job at the factory, the plain weave wire mesh has got you covered. Its properties(durability, strength and versatility) have made it a desired material for many types of projects. As we all know, Xuancheng is a professional company to manufacture plain weave wire mesh with high-quality. Their products come in the widest selection of fabrics and sizes so that you are sure to get what you need for whatever project is on your mind.

A skilled team of after-sales service is available to provide full technical and customer service. This can be done via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to get their feedback on their current usage of filters and future expectations. By collecting customer feedback and issues that arise in the service after sales department, it can respond rapidly and give timely treatment or respond. At the same time the feedback is passed back to the design department or production department to promote the constant improvement of products and services. The expert team analyzes the root of the problem and provides solutions to make it less likely to occur repeating. When the two are in harmony, can we provide customers with an exceptional after-sales customer experience. This improves customer satisfaction and helps the growth of the enterprise.

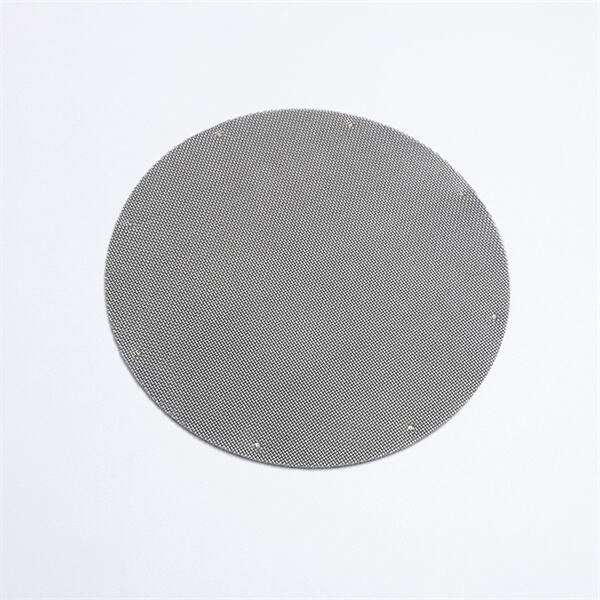

Yangzhou Xuancheng Filter Screen Co., Ltd., one of the producers of extruder screening has been devoted to the development and production of plastic extrusion filters for a number of years. They have amassed the most extensive technical knowledge and have gained experience in this business. They are extensively used in the industries of plastic granulations modified by granulations recycling granulations, extrusions made of sheets and films, and many others along with the filtration of chemical fibers. There is a broad range of products that include filters, edging meshes, spot-welded meshes stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators and so on. offering a variety to meet the varied needs of the customers. It has provided services to more than 500 prominent plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great branding influence. The company has a high technical power, a high degree of specialization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

The extruder filter is constructed of high-quality metal and has a fine filter pore size, which effectively removes any impurities that are present in the polymer melt as well as improve the quality and purity of the final product. The filter's structure is designed to ensure a continuous filtration rate while the material flows through it, which reduces the chance of clogging. This increases the efficiency of production. Metal filters are impervious to wear, corrosion and high temperatures. In accordance with the diverse requirements of customers and the specific specifications of the extruder, specific filter solutions can be provided to ensure an ideal match with existing equipment, and to provide the highest performance in filtration. A high-performance filtration system decreases the amount of interruptions caused by the accumulation of impurities and increases productivity.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy