Plastic stainless steel fine mesh screen is mainly used when creating things out of plastic such as: fun toys, and useful containers. This window is, in fact very crucial as it provides assurance that the plastic has been perfectly formulated and free from any spoil elements.

In this video when we are making a product out of plastic, the 1st step is to heat until it melts. This eventually turns the solid plastic into a viscous fluid. After the melting is completed, it moves to a special machine named extruder. A giant screw turns inside the extruder to push melted plastic out of a tiny hole. The extruder screen is inserted right at the end of that hole. The screen is a type of filter catching any dirt or bad material that could be mixed with the plastic. If we had not used this screen – these unwanted things would seriously harm the final product by rendering it weaker or unsafe.

The extruder mesh screen grabs the bad stuff and, in turn; filters it out to ensure cleanliness of plastic. While clean plastic might not add anything to the final product (aside from performing as expected), dirty means lower-quality performance. When we recycle, for instance plastic — having clean one actually allows the container to keep its shape and live longer. This is one of the most important aspects when we look to buy containers as they need strength, and ideally that same box should be impervious for our food or anything which needs storing.

There are so many advantages to using these extruder mesh screens. Primarily, they help ensure that the end product is high-quality – which can make a world of difference to customers. The second is that these screens aid in the piece of equipment itself living longer, as a result because they prevent dust and other impurities from bogging it down. In such a case, we must stop and clean the machine that can also be time & effort consuming. Finally, you can save time and money with an extruder mesh screen because it eliminates the need for additional clean up to your plastic. On one hand, factories get to work faster than they are always able to produce more enforceable products.

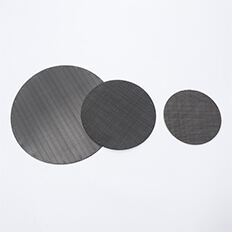

There are various types of extruder mesh screens available as per the specific needs and requirements of project. They can be of various size holes, and would depend on what we are trying to produce, just like each screen is made from other material. The choice of the correct extruder mesh screen goes a long way in ensuring greatest results from your extensive range projects. For example, some projects may require a screen with extremely fine holes to capture particles that are minuscule in size while others might want something with larger gaps. Extruder Mesh x GREX offer a wide assortment of extruder mesh screens in Xuancheng helping you to buy the right one for your requirements.

Meshed screens of the extruder are not only used to do a product with plastic. In addition to medical and food technology they are also very helpful in the industry. For instance, in the food sector extruder mesh screens are able to ensure tastiness of lovely products like breakfast cereal and pasta. They care that these food products are safe to eat and importantly, they contain clean ingredients. Extruder mesh screens in the medicine industry can be used to generate essential drugs. Proof in the pudding, medication regulators know it is crucial for their scoops to be uncut and uncontaminated. Extruder Mesh Screens, All You Need to Know Extruder mesh screens are a device that is designed for use anywhere where cleanliness of the final product must be ensured.

A skilled team of after-sales service is available to provide full technical and customer service. This can be done via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to get their feedback on their current usage of filters and future expectations. By collecting customer feedback and issues that arise in the service after sales department, it can respond rapidly and give timely treatment or respond. At the same time the feedback is passed back to the design department or production department to promote the constant improvement of products and services. The expert team analyzes the root of the problem and provides solutions to make it less likely to occur repeating. When the two are in harmony, can we provide customers with an exceptional after-sales customer experience. This improves customer satisfaction and helps the growth of the enterprise.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

The filter in the extruder is constructed of top-quality metal, and it has tiny pores for filtering. This permits it to eliminate impurities and improve the purity and quality of the polymer. The structure of the filter is designed to ensure that the material flow remains stable in filtration throughout its passage, reducing clogging and improving production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. Filter products that are custom-designed can be found to meet the requirements of different customers, and to match the equipment. A high-performance filtration system reduces the amount of delays caused by clogging of impurities and boosts the productivity.

The customized service includes the selection of filter pore size along with the shape, material as well as other elements and is able to provide custom filter products according to the different needs of customers and the specific specifications of the extruder. With the help of customized services, structure as well as the material, filtration efficiency and other aspects of the filter are able to be improved, so as to improve the efficiency of filtration and extend its the life of the filter. The process is designed according to the actual needs of the client, thus avoiding the waste that is unnecessary, and aiming to save customers money. In accordance with the specific requirements and applications of customers, taking into consideration the specific demands such as corrosion resistance and high temperature resistance wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron and more. Based on the use of the customer's surroundings and conditions for installation make sure you design a functional filtering structure, like types of plates, wound types or cylindrical type, for example.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy