A stainless filter screen is a type of industrial air filtration system. It is a type of filter and it made over wire mesh. In other words, it is composed of numerous small wires intertwined. You can use these filters in a host of different spots. They excel at cleaning both gases and liquids, as well as tiny solids. This is available in every oil, food, drinks and medicine manufacturing factory as steel woven wire meshs. It ensures that the products manufactured elsewhere thru these factories are clean and safe.

The good thing is that the wire mesh cylinder filters do perform decently well. Due to the fact that they are only 1 micron in size, these mask filters can help catch even smaller particles. A micron is a minuscule unit as compared to the thickness of human hair (mind it, horses do this with 50 microns. This is why these filters can easily remove tiny impurities and dirt from gas or liquid. These are better than some other filters because they tend to clean themselves evenly across the entire surface. Washing in this uniform manner is the standard because it guarantees noides in any part of fluid or gas left contaminated.

These 316 stainless steel wire meshs are designed to help protect expensive machines and keep them running. Dirt, dust and debris will eventually clog your machinery to the point it does not function correctly or even at all. This can result in expensive repairs and downtime, which is when a machine is not running. You can use the wire mesh cylinder filter to keep machines free of dirt. This means that they will function well, provide good longevity and require minimal to no fixing or maintenance in the long run. We have to clean our rooms so that the machines also have to be kept in property working conditions.

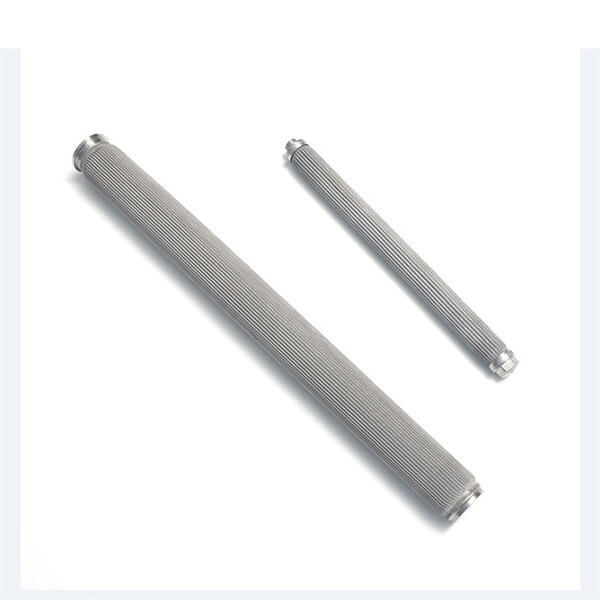

Wire mesh cylinder filters have versatile utility in different systems and location such as hydraulic system, lubrication system,cooling system etc. In the picture on your left you can note that wire mesh filters are used in hydraulic systems which, help to reduce wear of important parts for machinery movements. They are used in lubrication systems to prevent oils and greases from losing their cleanliness, resulting frictionless movement of the machines. Wire mesh, used for cooling systems in order to prevent pipe blockage due to debris. Clogged pipes or drains can lead to critical long-term issues for the machines that they serve.

While selecting a wire mesh cylinder filter, you have to check where can it be used and which sort of liquid or gas will likely clean the support. The size of the filter also matters because it can impact how quickly things flow through. If the filter is too little, it can easily stoppage but if that will be extremely large then simply this may definitely not grab filth. In addition, it will depend on the volume of dirt that is in your liquid or gas to decide which mesh size you should be using.

If you ever need the perfect mesh cylinder filter for your job, then Xuancheng is the company that can help you. They are experts in the field and can point you to the best-filter model for your specific case. They know the different requirements of industry and advice what will suit you better.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters which has been dedicated for many years to the development and production of plastic extrusion filters, and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of sheets, films and other industrial processes, as well as the filtration of chemical fiber spinning and other industries. They comprise filter mesh, edging mesh spot welded mesh, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor mesh belt wire mesh mist eliminator and so on., with a complete collection to meet the needs of different customers. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great brand influence. The company is equipped with strong technical strength and has the most advanced production equipment, as well in a complete test method. The company has been accredited to ISO9001:2015 to ensure a stable and reliable product.

The filter in the extruder is made of premium metal with very fine pores. This helps to eliminate contaminants and enhance the quality and purity of the polymer. The structure of the filter is designed to ensure a high efficiency in filtration while the material is flowing through it, thus reducing the possibility of the likelihood of clogging. This increases the efficiency of production. The metal filter is highly resistant to resistance to corrosion, wear and high temperatures. Customized filter products are available to satisfy the requirements of different clients, and also to fit with the equipment. A high-performance filtration system decreases the time lost to interruptions caused by the accumulation of impurities and boosts the productivity.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

The company is equipped with a skilled after-sales service department, which is accessible via phone, online customer service or social media, as well as other communication methods, can quickly provide customers with technical support, consultation on products as well as cargo tracking along with troubleshooting services. After the goods are sold, regular and in-depth communication with the client is made to know the use they are currently making of their filters, as well as the needs of the future and their expectations. In gathering feedback from customers as well as issues encountered in the service after sales department, it can respond rapidly and give timely treatment or respond. Moreover, the feedback is also fed back to production and design departments to enhance the quality of products and services. The expert team examines the root of the problem and provides basic solutions to minimize the chance of repeating the same problem. The two complement one another and only then can we provide our customers with the highest quality customer service. This, in turn, can increase customer satisfaction and allow the business to expand.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy