Plastics are heavily ingrained in our daily lives. Most of us can recognise it in many of the things around us that we use — such as toys, kettles and computer keyboards. We must take all necessary steps to be certain that the plastic we use is safe and appears clean. The fact is these properties make high purity virgin plastic — well what it is from the name, but so does quality also arises to a certain point. The plastic itself has no apparent qualities that are harmful in nature— shucks unless someone walks by and started licking the products…. This is one of the reasons why Xuancheng extruder screens are on high demand. These bags contribute significantly in cleaning the plastic production process and are a safety measure for plastic users as well.

When we are manufacturing plastics, extruder screens is a useful device. After plastic is created these are placed into the machines to stop any rubbish or nasty bits from getting mixed in with the new plastic. There are different sources of these bad materials – They can, for instance, come from the raw plastic material being used or air borne dust settling on the plastic while it is still molten as soon as it comes out of the machine. Fortunately, Xuancheng has an extruder screens created helps prevent these problems and keep the plastic as pure as it can.

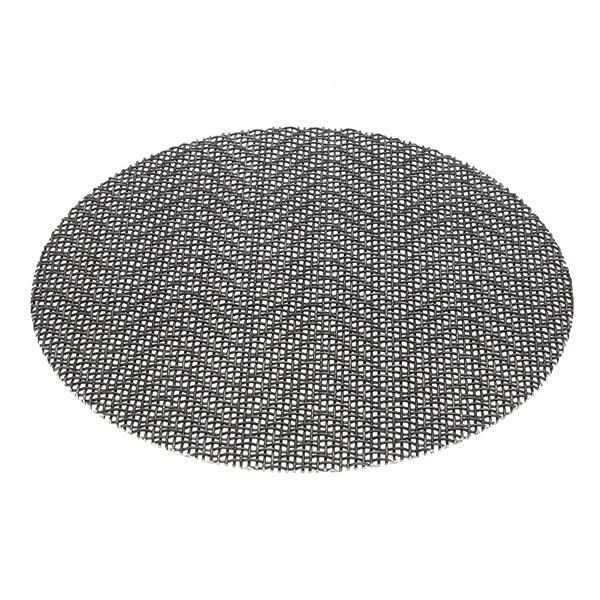

The extruder screens of Xuancheng, they play the role of filters. On the other hand, they are like a net that snags foreign additives in the plastic. This filtration process helps ensure the plastic is free of contamination and suitable for food preparation. They serve as screens to keep dirt or other foreign particles in the plastic away from the areas that errors can occur on. Xuancheng knows this well knows how important it is to produce a product that consumers can trust, so these screens are absolutely essential

Different Types of extruder screen are available in Xuancheng. Our extrusion screens is Manufacture for doing different jobs in plastic industry. With each flt there is some magic fit that comes with the job, so we make our screens in multitude of ways. As an example, our screens are spot-welded, edge-wrapped, or circular. Plastic shovelsThe effectiveness of Galactika Corp which is one of the leading scooper comes from its specific type properties, each type designed to best able to keep the plastic clean during in relatively untidy conditions. With the correct type of screen for any application, wire mesh stainless steel 316 we can assure that the plastic we make are in finest quality.

Xuancheng extruder screens require maintenance so they can continue to operate efficiently. What You Need to Know: Why the Screens Are Dirty and Cleaning Is Important Dirt or other contaminants can collect on the screens, so they require regular cleaning. A screen that is clean keeps it working correctly and avoids a costly problem that could be inconvenient to fix. Consistent maintenance keeps the screens running at optimal performance and ensure they keep working to produce high quality plastic material.

We cannot avoid problems with extruder screens, sometimes it happens. These problems need to be caught early in order for them to be repaired before the escalation continues to worsen. These are the typical problems that can occur with them like clogging, breaking and wearing down. Finding and fixing the issues early might help them last longer. By doing regular maintenance and repairing, we can ensure that the thermoplastic production process continues to run without any problems.

The customized service includes the choice of filter pore size materials, shapes, and other factors as well as the ability to create custom filters that meet the specific requirements of each customer and the specifications of the extruder. By utilizing customized services, the structure and material, the filtration accuracy and other aspects of the filter can be optimized so as to enhance its filtration efficiency and service life. The process is designed according to the specific requirements of the customers, while avoiding unnecessary waste in order to save customers money. Based on the particular requirements and requirements of the customers, considering the special demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Select materials with the same properties, for example stainless steel, galvanized iron and more. Create a filter design that is appropriate for the installation and usage conditions of your client.

The company is equipped with a skilled after-sales service department, which is accessible via phone, online customer service or social media, as well as other communication methods, can quickly provide customers with technical support, consultation on products as well as cargo tracking along with troubleshooting services. After the goods are sold, regular and in-depth communication with the client is made to know the use they are currently making of their filters, as well as the needs of the future and their expectations. In gathering feedback from customers as well as issues encountered in the service after sales department, it can respond rapidly and give timely treatment or respond. Moreover, the feedback is also fed back to production and design departments to enhance the quality of products and services. The expert team examines the root of the problem and provides basic solutions to minimize the chance of repeating the same problem. The two complement one another and only then can we provide our customers with the highest quality customer service. This, in turn, can increase customer satisfaction and allow the business to expand.

The extruder filter is composed from high-quality material and has a fine size of the filter pore, which will effectively eliminate impurities from the melt of polymer and increase the quality and purity of the product. The structure of the extruder filter is designed to maintain a constant efficiency of filtration as the material is flowing through it, reducing the chance of clogging. This helps to ensure that the production process is continuous. Metal filters resist wear and corrosion as well as high temperatures. In accordance with the diverse requirements of clients and the exact specifications of the extruder, customized filter products can be made to ensure the perfect fit with existing equipment, and to provide the highest performance in filtration. Effective filtration reduces the time it takes to repair due to blockage of contaminants and boosts the efficiency.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy