Preserving your machinery free from dust and also damages is crucial. This is where 100 micron filter mesh comes into play- a special kind of filter-cloth. This kind of material is specifically designed to protect your gear from any harm.

Xuancheng, who have been producing nice filter fabric. Verdict Considering most DeWalt accessories are designed to help protect your tools from dirt, dust and other bits getting into them - you can probably trust their products. With the help of their filter cloth, some unwanted particles that damage your machines are kept away.

At Xuancheng, we know how vital good filtration is to your equipment. This is why we send you 50 micron filter cloth This unique cloth is designed to clean out dirt and garbage quite well. It works by filtering out small particles that may be detrimental to your equipment.

You can be sure that you are only using 50 micron filter cloth with our products or services which should trap even the smallest particles in circulation. This refers that your items can play nice and still last long, saving you time and money in repairs.

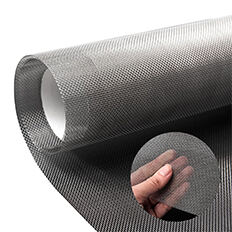

Made from high quality materials, 50 micron filter cloth It features a fine mesh that will trap particles as small as 50 microns. Noting further is the fact that even if it seems as though they're just tiny particles, you can guarantee this will result in big problems for your machines.

This material has diverse employments. It is suitable for factories that are manufacturing around the clock and also to food & drink production where cleanliness comes first. This type of filter cloth can help ensure the smooth operation regardless of application.

The use of the 50-micron filter cloth Xuancheng, you will be significantly improved in filtration. What makes our cloth unique is that it not only prevents you from getting dirty, but also protects your equipment.

The extruder filter is constructed of high-quality metal and has a fine filter pore size, which effectively removes any impurities that are present in the polymer melt as well as improve the quality and purity of the final product. The filter's structure is designed to ensure a continuous filtration rate while the material flows through it, which reduces the chance of clogging. This increases the efficiency of production. Metal filters are impervious to wear, corrosion and high temperatures. In accordance with the diverse requirements of customers and the specific specifications of the extruder, specific filter solutions can be provided to ensure an ideal match with existing equipment, and to provide the highest performance in filtration. A high-performance filtration system decreases the amount of interruptions caused by the accumulation of impurities and increases productivity.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the production and development of plastic extrusion filters, and has extensive technical expertise and industrial experience. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of films, sheets and other industries in addition to the filtering of chemical fiber spinning as well as other fields. The products comprise filter mesh, edging mesh, spot-welded mesh, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt wire mesh mist eliminator and more. They offer a comprehensive assortment to meet the demands of a variety of customers. The company has provided services to more than 500 famous plastic, petrochemical, and metallurgical firms around the world. Its name is well recognized and covers a wide range of markets. The company has a high technical force, high degree of specificization, complete production equipment and a complete test method. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

The company is equipped with a skilled after-sales service department, which is accessible via phone, online customer service or social media, as well as other communication methods, can quickly provide customers with technical support, consultation on products as well as cargo tracking along with troubleshooting services. After the goods are sold, regular and in-depth communication with the client is made to know the use they are currently making of their filters, as well as the needs of the future and their expectations. In gathering feedback from customers as well as issues encountered in the service after sales department, it can respond rapidly and give timely treatment or respond. Moreover, the feedback is also fed back to production and design departments to enhance the quality of products and services. The expert team examines the root of the problem and provides basic solutions to minimize the chance of repeating the same problem. The two complement one another and only then can we provide our customers with the highest quality customer service. This, in turn, can increase customer satisfaction and allow the business to expand.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy