Need a material that will help you meet your filtering requirements with ease? Then you must read the following to know more about xuancheng stainless steel metal mesh! This incredible material is an excellent work-horse, and comes from many different parts of the world. Besides, it is very practical and can serve you for many tasks, so it becomes the right option for those who want to have an excellent performance.

Xuancheng's 304 Stainless Steel Mesh — Best for a Variety of Environments The mesh is engineered to endure extreme temperatures, moisture and can even resist major chemical changes. Whether you are labouring in a hot factory or a wet kitchen, this mesh has it all! It is ideal for de-dusting, screening & separation of fine particles. Additionally, as it can be readily sourced, you have the flexibility to use it in a simple home project through to an intricate industrial application.

First and foremost, stainless steel mesh is an incredibly durable basket that will last for years. Including the all-time reach, non-toxic and environmentally friendly corrosion resistance, it will be safe from rusting or from other breakdown. It is an ideal choice for heavy-duty environments, in which other types of materials might suffer. This mesh can be used in a chemical plant, or outside against the elements. With a robust feature set you can trust the Fluke 376 to work Accurately and in demanding environments providing readings which will allow you to complete your tasks successfully.

This metal can be found across a wide array of industries, all with the trust bestowed in Xuancheng 304 stainless steel mesh because it works. This mesh is used in a wide range of businesses from chemical processing to food and beverage production, as well. It is also applied in the oil and gas industry, for filtering contaminants like dirt. This is to ensure for uninterrupted and safe production. This mesh is chosen by companies because they know it accelerates the way in which that can get their work done, while at the same time allowing to sleep soundly knowing that no failures or breakdowns will be occurring any time soon.

Xuancheng 304 stainless steel mesh-When you are still hesitating to take the high-quality one in cheap price It is manufactured with utmost care ensuring its reliability. And, it is available in a variety of sizes, so if you are looking for small binding or large rolls, Xuancheng has what you need. This option is good for any kind of platform due to its flexibility.

The 304 stainless steel mesh of Xuancheng is custom-made to guarantee the most superior. These fabric face masks are woven to a precise density that helps filter out very small pieces of stuff, you know the tiny bits and particles that's too small for your puny human eye. This is especially important when you want to ensure your products are safe and clean. You can rest assured that you are going to get the best possible results with this mesh, and that is what makes it such a useful tool for anyone who needs to complete serious filtering or separating tasks.

A skilled team of after-sales services is on hand to provide complete technical and service support. This can be done by calling the company's number, online customer service and social media. When the products are purchased, regular communication with the buyer is conducted to gain an understanding of the usage of their filters, as well as the future requirements and expectations. The after-sales team can address customer concerns and feedback quickly by collecting the details. Additionally, feedback from customers is also passed back to the product design and production departments in order to improve the quality of products and services. The experienced team examines the root of the problem and provides key solutions to decrease the frequency of this issue. Only when the two complement each other can we give customers an exceptional after-sales customer experience. This enhances customer loyalty and aids in the long-term growth of the enterprise.

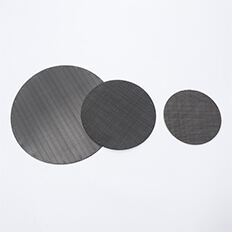

The extruder filter is constructed of high-quality metal and has a fine filter pore size, which effectively removes any impurities that are present in the polymer melt as well as improve the quality and purity of the final product. The filter's structure is designed to ensure a continuous filtration rate while the material flows through it, which reduces the chance of clogging. This increases the efficiency of production. Metal filters are impervious to wear, corrosion and high temperatures. In accordance with the diverse requirements of customers and the specific specifications of the extruder, specific filter solutions can be provided to ensure an ideal match with existing equipment, and to provide the highest performance in filtration. A high-performance filtration system decreases the amount of interruptions caused by the accumulation of impurities and increases productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd., an extruder screen manufacturer is devoted to the design and manufacture of plastic extrusion filter for a long time. They have amassed vast amounts of technical expertise and know-how in the field. They are extensively used in the fields of plastic modified granulations recycling granulations, extrusions made of films and sheets and many more in addition to filters for spinning chemical fibers. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor belt, wire mesh mist eliminator, and so on. They offer a comprehensive collection to meet the needs of a variety of customers. The company has served over 500 well-known plastic, petrochemical and metallurgical companies around the world. The brand is well known and it is able to cover a variety of markets. The company has strong technical strength and possesses specialized production equipment, as well with a comprehensive testing process. The company has been accredited to ISO9001:2015 to ensure a stable and reliable product.

Customized services consist of the selection of filter material dimensions, pore size and shape and other aspects. They can also provide custom-designed filters based on customer demands and specifications of the extruder. Customized services enable the optimization of filter parameters like structure materials, filtration precision and other parameters. This will increase the filter's filtration efficiency and lifespan. The manufacturing process is based on the requirements of the client, and waste is avoided to lower costs. Choose the materials with most suitable properties for the requirements and situations of the client in consideration of the needs for heat resistance, corrosion resistance, wear resistance and so on. Choose a filtering structure that will be suitable for the installation and usage requirements of your client.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy