تحتاج إلى مادة تساعدك في تحقيق متطلبات الترشيح الخاصة بك بسهولة؟ إذن عليك قراءة التالي لمعرفة المزيد عن xuancheng شبكة معدنية من الفولاذ المقاوم للصدأ ! هذه المادة الرائعة هي خيار ممتاز، وتأتي من العديد من أنحاء العالم. بالإضافة إلى ذلك، فهي عملية للغاية ويمكنها تنفيذ العديد من المهام، مما يجعلها الخيار الصحيح لأولئك الذين يرغبون في الحصول على أداء متميز

شبكة الفولاذ المقاوم للصدأ 304 من xuancheng - الأنسب لعدد كبير من البيئات تم تصميم الشبكة لتتحمل درجات الحرارة الشديدة والرطوبة ويمكنها حتى مقاومة التغيرات الكيميائية الرئيسية. سواء كنت تعمل في مصنع حار أو مطبخ رطب، فإن هذه الشبكة تحتوي على كل شيء! إنها مثالية لإزالة الغبار، والغربلة وفصل الجزيئات الدقيقة. بالإضافة إلى ذلك، نظرًا لأنها يمكن الحصول عليها بسهولة، لديك المرونة لاستخدامها في مشروع منزلي بسيط وحتى في تطبيق صناعي معقد

أولاً وأهم شيء، شبكة فولاذية مقاومة للصدأ هي سلة متينة للغاية ستستمر لسنوات. تشمل مقاومة التآكل مدى زمني طويل، وخالية من السموم والصديقة للبيئة، مما يجعلها آمنة من الصدأ أو التلف بأشكال أخرى. إنها خيار مثالي للبيئات الشاقة، حيث قد تعاني أنواع أخرى من المواد. يمكن استخدام هذه الشبكة في مصنع كيميائي، أو في الخارج ضد العناصر الطبيعية. مع مجموعة مميزة من الميزات يمكنك الوثوق بأن Fluke 376 سيعمل بدقة وفي بيئات صعبة، مما يتيح لك إتمام مهامك بنجاح.

يمكن العثور على هذا المعدن في مجموعة واسعة من الصناعات، وكلها تعتمد على الثقة الممنوحة لشبكة الفولاذ المقاوم للصدأ Xuancheng 304 لأنها تعمل. تُستخدم هذه الشبكة في مجموعة متنوعة من الأعمال، من معالجة الكيماويات إلى إنتاج الأغذية والمشروبات أيضًا. كما تُستخدم في صناعة النفط والغاز لتصفية الشوائب مثل الطين. الهدف من ذلك هو ضمان الإنتاج الآمن والمستمر. تختار الشركات هذه الشبكة لأنها تعلم أنها تسريع العمل الذي يمكنهم إنجازه، وفي نفس الوقت تمنحهم الراحة في النوم دون قلق من حدوث أعطال أو توقف قريب.

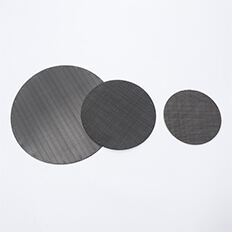

شبكة الفولاذ المقاوم للصدأ Xuancheng 304 - عندما تتردد لا تزال في اتخاذ واحدة ذات جودة عالية بسعر رخيص، يتم تصنيعها بعناية فائقة لضمان موثوقيتها. كما أنها متاحة في مجموعة متنوعة من الأحجام، لذلك إذا كنت تبحث عن حزم صغيرة أو أسطوانات كبيرة، فإن Xuancheng لديها ما تحتاجه. هذه الخيار مناسبة لأي نوع من المنصات بسبب مرونتها.

شبكة الفولاذ المقاوم للصدأ 304 من Xuancheng مصممة خصيصًا لضمان الأفضلية العظمى. يتم نسج هذه الأقنعة القماشية بكثافة دقيقة تساعد في تصفيت المواد الصغيرة جدًا، تلك القطع والجسيمات الصغيرة جدًا التي تكون صغيرة جدًا بالنسبة للعين البشرية. هذا مهم بشكل خاص عندما تريد التأكد من أن منتجاتك آمنة ونظيفة. يمكنك أن تطمئن إلى أنك ستحصل على أفضل النتائج الممكنة مع هذه الشبكة، وهذا هو ما يجعلها أداة مفيدة جدًا لأي شخص يحتاج إلى إكمال مهام التصفية أو الفصل الجدية.

يوجد فريق ماهر من خدمات ما بعد البيع جاهز لتقديم الدعم الفني والخدمي الكامل. يمكن القيام بذلك عن طريق الاتصال برقم الشركة، أو خدمة العملاء عبر الإنترنت ووسائل التواصل الاجتماعي. عند شراء المنتجات، يتم إجراء اتصال منتظم مع المشتري لفهم استخدامهم للفلاتر الخاصة بهم، وكذلك المتطلبات والتوقعات المستقبلية. يمكن لفريق ما بعد البيع التعامل بسرعة مع مخاوف وتقييمات العملاء من خلال جمع التفاصيل. بالإضافة إلى ذلك، يتم نقل تقييمات العملاء أيضًا إلى أقسام تصميم وإنتاج المنتجات من أجل تحسين جودة المنتجات والخدمات. يقوم الفريق ذو الخبرة بفحص جذور المشكلة ويقدم حلولًا أساسية لتقليل تكرار هذه المشكلة. فقط عندما يكمل كل منهما الآخر يمكننا تقديم تجربة استثنائية للعملاء فيما يتعلق بخدمة ما بعد البيع. هذا يعزز ولاء العملاء ويساعد في النمو طويل الأمد للشركة.

يُصنع مرشح الخلاط من معدن عالي الجودة وله حجم فتحات مرشح دقيقة، مما يزيل بفعالية أي شوائب موجودة في انصهار البوليمر ويحسن جودة ونقاء المنتج النهائي. تم تصميم هيكل المرشح لضمان معدل ترشيح مستمر أثناء تدفق المادة من خلاله، مما يقلل من فرصة الانسداد. هذا يزيد من كفاءة الإنتاج. المرشحات المعدنية مقاومة لل摩损 والتآكل والدرجات العالية من الحرارة. وفقًا لمتطلبات العملاء المختلفة والمحددات الخاصة بالخلاط، يمكن تقديم حلول مرشح محددة لضمان توافق مثالي مع المعدات الموجودة ولتقديم أفضل أداء في الترشيح. نظام ترشيح عالي الأداء يقلل من عدد الانقطاعات الناجمة عن تراكم الشوائب ويزيد من الإنتاجية.

شركة Yangzhou Xuancheng Filter Screen Co., Ltd., وهي شركة متخصصة في تصنيع شاشات البثق، مكرسة لتصميم وإنتاج مرشحات البثق البلاستيكية منذ فترة طويلة. لقد جمعوا كمية كبيرة من الخبرة الفنية والمعرفة في هذا المجال. يتم استخدامها على نطاق واسع في مجالات إعادة تدوير الحبيبات المعدلة والبلاستيكية، وبثق الأفلام والألواح وغيرها، بالإضافة إلى فلاتر خيوط الألياف الكيميائية. تتضمن منتجاتهم مرشحات، شبكات حدودية، شبكات اللحام النقطي، أحزمة شبكة الفولاذ المقاوم للصدأ ذات التبديل التلقائي، شبكات التعزيز، ناقلة الحركة، ومرشحات الضباب الشبكي، وما إلى ذلك. توفر الشركة مجموعة شاملة لتلبية احتياجات مجموعة متنوعة من العملاء. وقد خدمت أكثر من 500 شركة معروفة تعمل في مجالات البلاستيك والبتروكيماويات والمعادن حول العالم. العلامة التجارية معروفة جيدًا ويمكنها تغطية مجموعة متنوعة من الأسواق. تمتلك الشركة قوة تقنية كبيرة وتتمتع بمعدات إنتاج متخصصة، بالإضافة إلى عملية اختبار شاملة. وقد حصلت الشركة على شهادة ISO9001:2015 لضمان منتج مستقر وموثوق.

تتألف الخدمات المخصصة من اختيار أبعاد مواد الفلتر، وحجم وشكل المسامات وغيرها من الجوانب. يمكنها أيضًا تقديم فلاتر مصممة حسب الطلب بناءً على متطلبات العملاء ومواصفات ماكينة التشكيل. تمكن الخدمات المخصصة من تعزيز معلمات الفلتر مثل مواد الهيكل، ودقة الترشيح والمعلمات الأخرى. هذا سيرفع كفاءة ترشيح الفلتر ويعيد عمره الافتراضي. يتم تنفيذ عملية التصنيع بناءً على متطلبات العميل، ويتم تجنب الهدر لتقليل التكاليف. اختر المواد التي تتمتع بالخصائص الأكثر ملاءمة لاحتياجات ومواقف العميل مع الأخذ في الاعتبار الحاجة إلى مقاومة الحرارة، ومقاومة التآكل، ومقاومة الاحتكاك وما إلى ذلك. اختر هيكل ترشيح يناسب متطلبات التركيب والاستخدام الخاصة بعميلك.

جميع الحقوق محفوظة © شركة يانغتشو شوانشينغ لصناعة الشاشات المرشحة المحدودة - سياسة الخصوصية