Hello readers! Now let us talk about one product today, it is extremely special called xuanchengs steel woven wire mesh. That may sound like a terrifying and complex word… fear not! We will simplify all this for you, in a layman term.

Stainless steel fine wire mesh provides much strength and toughness. Stainless steel is used to make this, so with it without breaking or being damaged by very high and low temperatures. This material even does not let rust in. And this ensures that it lasts a very long time on various occasions, including outdoor uses. It is also super easy to clean, so you would not need to worry about using it outside in garbage weather. This mesh is also pliable, not to mention it can be formed into a variety of shapes and sizes as the situation calls for.

Here are some applications and industries where stainless steel screen wire is used: You can see it in construction sites, farms and factories for instance. This mesh is used to strengthen concrete, rep weave strong fences and clean airs and liquids. Use: For example, it is very significant in the food industry where cheese and sausage By-products from pigs are made. The most important asset of this material is the plethora if uses it can be put to; making in irresistible for many different jobs.

Therefore, stainless steel fine wire mesh is very important in cleaning. It is capable of removing wastes in water and air. Such meshes are used to filter water for us drinking possibilities too such as in water treatment plants. All of which ensures clean air in hospitals and eliminates germs, pathogens etc... This web is necessary to maintain the safety and purity of water we drink, air that we breathe.

It is flexible and can be used in various workiscoefficients. It is durable, long-lasting and malleable enough to mold it into different forms as required. This means it provides to plenty of sectors e. g., production and building, the agricultural business as well as in food handling facilities fights swears by this tool making it an excellent choice for them. Nearly any industry Stainless steel fine wire mesh can be found due to the versatility and effectiveness.

Then how about stainless steel fine wire mesh, look at xuancheng_EDEFAULT We have just what you need! This is a long-lasting mesh that holds up under various temperatures and weather conditions. And it is very low maintenance too, which is a big positive sign. We provide a variety of stainless steel fine wire mesh items, and all your needs can be customized at xuancheng. If you need assistance finding the right mesh for your job, our professionals are here to help.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

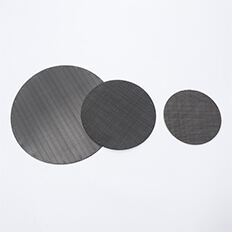

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

The company has a professional after-sales service team, through the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical assistance, product advice as well as cargo tracking as well as troubleshooting services. The company will contact customers regularly after the sale to find out their usage of filters and to anticipate their needs for the future. After-sales personnel is able to respond to customer issues and comments quickly by gathering the data. Additionally, feedback from customers can be passed on to the product design and production departments in order to improve the quality of products and services. The expert team determines the source of the issue, and then provides fundamental solutions to reduce the likelihood of repeating the same problem. The two are in sync and only then can we provide our customers with the highest quality customer service. This in turn can increase customer satisfaction and allow the business to increase its growth.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy