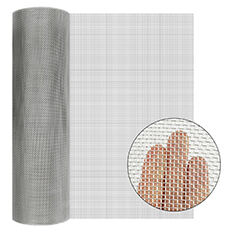

WE NEED to keep our IMMEDIATE surroundings CLEAN AND SAFE. Filters are significant for it. Those little pieces that would wreck havoc inside of machinery or even in our bodies; they take them away. Xuancheng Tubular filter mesh is a kind of liquid filtration with high performance. This unique filter consists of tiny shards of powerful stainless-steel wire that can be cleaned and reused, as often as necessary. So, here we have been some awesome benefits of 100 micron filter mesh in liquid filtration.

Tubular filter mesh ▽First of all, task does steel woven wire mesh perform? The minuscule holes in its fine mesh can collect even the tiniest specks of dirt, dust and other contaminants. This is what makes it an excellent piece of tool for a host of industries, including food and beverage production where immovably clean liquids are must. The material is strong against acids and bases, mesh products are available as well. The reason this doesn´t damage the valve is because it can withstand all of these chemicals that are usually found in an industrial process.

Another benefit of steel woven wire mesh is that this material is very easy to install and maintain. It adds relatively little in the way of bulk – you can easily fit one to a pipe, tank or container without making it difficult for other systems that sit alongside. The mesh is made using materials that are strong therefore the screen sheet can be cleaned and reused several times without having to replace it every now & then. Not only is this cheaper but also less wasteful and can be actually better for the environment.

Yes, the HVAC system – that would be short for Heating, Ventilation and Air Conditioning- is key to ensuring a safe living environment in occupied buildings. Which is what it mostly does, filtering the air and providing clean and nice smelling human ambient at a suitable temperature. The HVAC system having to work harder, in case when the filters get dirty. This results in increased energy bills, poor air quality and a less durable life of the equipment.

Tubular Filter Mesh for More Air Power in HVAC Systems Aluminum mesh is increasingly common with notoriety because It can greatly enhance the airflow of interior heating and cooling systems. This air filter has a fine mesh that allows free flow of air but the dust, dirt and pollen particles are trapped in its tiny pores. This way your HVAC system can function effectively. It not only helps keep the air cleaner but also in turn saves you money by reducing energy costs to run the system.

It is a small hole that you can make even the smallest particle or material with up during production in design mesh. Product quality is improved due to the higher filtering efficiency and maintenance costs are lowered. In addition it helps ensure worker safety since cleaner materials are easier to work with. This type of filtering solution is widely used by industrial professionals for a spectrum of different applications which could be as varied from providing filtration in pharmaceutical production, water treatment and chemical processing. One can try the stainless filter screen of Xuancheng, quality and safety improvements are bound to be observed in products manufactured using this.

MineralsIn addition to fuel, a very prominent raw material used in the cement industry is mineral. Effective filtering may require various meshes for different materials. The specifications of the tubular filter mesh we offer can be customized to your special requirements, and come with different wire diameters and openings that will satisfy you based on whatever materials are being filtered in your industrial procedures.

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

The company has a professional after-sales team, utilizing the phone, customer service online or social media, as well as other contact methods, can efficiently provide customers with technical support, consultation on products along with cargo tracking, troubleshooting and other comprehensive services. The company will contact customers on a regular basis after they have purchased to learn about their current usage of filters and their future plans. The after-sales department can handle customer complaints and feedback promptly by capturing the data. Furthermore, feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The expert team analyzes the cause of the issue and offers solutions that will decrease the chance of it repeating. Only when both work together can we offer customers an exceptional after-sales customer experience, which in turn strengthens customer loyalty and promotes the long-term growth of the company.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

The customized service consists of choice of the size of the filter's pore along with the shape, material and other aspects and will provide customized filters that meet the specific requirements of each customer and the particular specifications of the extruder. Customized services enable the optimization of parameters for filtering like structure, material, filtration precision and many more. This improves the filter's filtration efficiency and life. The production process is conducted in accordance with the needs of the customers, while avoiding unnecessary waste in order to save customers money. According to the specific needs and application scenarios of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance as well as wear resistance, high temperature resistance, etc. Select materials with the same properties, for example galvanized iron, stainless steel and more. Make sure the filter you design is appropriate for the installation and usage conditions of your client.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy