The 316 stainless steel welded wire mesh made by Xuancheng is a great option for all sorts of projects that people are going to be doing with this kind of material. It is a very rigid and durable mesh that lasts a long time, which is why so many builders and DIYers use it. That is the reason it is so much liked, because it can be used in various ways. Here, we will see some of the reasons why steel welded wire mesh is one of the best choices for many different projects.

Perhaps the greatest advantage of steel welded wire mesh is that it is incredibly strong. Its uses for making durable buildings and structures have been known to last so long. The mesh consists of hundreds of tiny wires which are securely fused together. This process gives the material a good strength and durability even. Steel welded wire mesh does not easily rust, which is a significant quality because it will also generally be used in outdoor projects or may face external weather conditions such as rain and winds.

one other nice benefit of these steel welded wire mesh columns is that they are very easy to living up beings. It can be cut, bent, and shaped to your project requirements. Being so versatile has made it a common choice for standardized construction projects. It is also used to make fences and other outdoor structures as it can be shaped according to the requirement.

For construction purposes, incorporating steel welded wire mesh into your plans is a wise idea. This can be like making the rudimentary even more strong. It can also be put inside of concrete so that you have a more solid foundation. This will allow the building to maintain its condition in future times. This reinforcement which also can be used to reinforce walls and other areas of the buildings. It simulates a cantilevered system which assists in distributing the weight of the building more evenly. This also can assist with not cracking and creating different issues as the building settles.

Steel welded wire mesh is arguably the best choice for your project when you are trying to pick a material. It provides a unique blend of strength, rigidity, and flexibility that is relatively hard to come by with other materials. These traits are highly valued by many builders and designers, which has made it a very popular choice in the industry. Yeah, and was not that expensive too usually! You can choose this wonderful type at a good price since it is easy to produce, and hence a fantastic option for all types of projects.

A notable point to mention is that it is environment friendly as well., In the sense, from this type of steel welded wire mesh too little harmful effect comes about. If necessary, it is recyclable and can be put to use again with minimal waste. For construction purposes, it is therefore a permanent alternative. It uses less energy to produce compared to most of the other materials reducing the quantum of pollutants being released into the atmosphere.

In a word, compared with other types of welded wire mesh, the steel wire mesh produced by Xuancheng has many advantages and can be used for different purposes. It is a strong and long-lasting material that can be modified for various applications. It is a favourite for construction projects due to its flexibility and an obvious choice for industrial applications as it is strong.

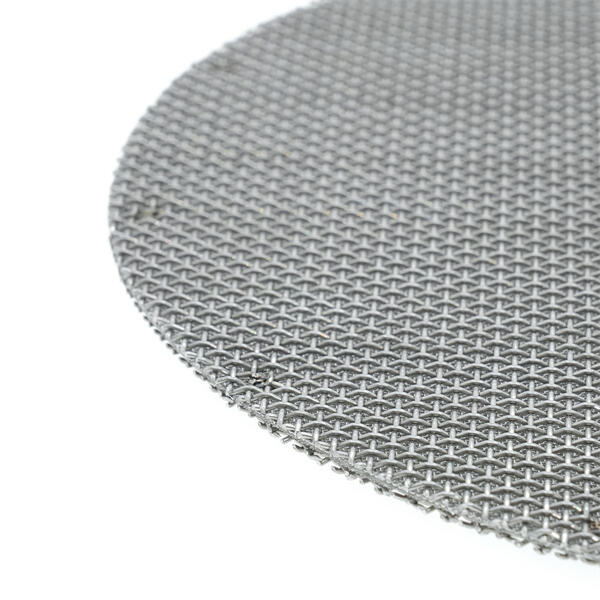

The extruder filter is constructed of high-quality metal material and has a precise filter pore size, which can effectively remove impurities in the polymer melt and increase the quality and purity of the product. The structure of the filter is designed to ensure a constant efficiency of filtration as the material moves through it, thus reducing the possibility of the chance of clogging. This helps to ensure that the production process is continuous. The metal filter is highly resistant to resistance to corrosion, wear as well as high temperatures. In accordance with the diverse requirements of the customers as well as the particular specifications of the extruder filters that are custom-designed can be designed to guarantee the perfect fit with existing equipment, and to provide the highest filtration effect. A high-performance filtering system can reduce the time lost to downtime caused by impurities clogging and also increases the efficiency.

The company has a professional after-sales service team, through the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical assistance, product advice as well as cargo tracking as well as troubleshooting services. The company will contact customers regularly after the sale to find out their usage of filters and to anticipate their needs for the future. After-sales personnel is able to respond to customer issues and comments quickly by gathering the data. Additionally, feedback from customers can be passed on to the product design and production departments in order to improve the quality of products and services. The expert team determines the source of the issue, and then provides fundamental solutions to reduce the likelihood of repeating the same problem. The two are in sync and only then can we provide our customers with the highest quality customer service. This in turn can increase customer satisfaction and allow the business to increase its growth.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

Yangzhou Xuancheng Filter Screen Co., Ltd., a manufacturer of extruder screens, has been dedicated to the design and manufacture of plastic extrusion filter for a long time. They have built up an extensive amount of technical know-how and have gained experience in this business. They are extensively used in the manufacture of granulations that are modified with plastic, recycling granulations, extrusions made of films and sheets and many more along with filters for spinning chemical fibers. There is a variety of products available, such as filters, edging meshes, spot-welded meshes stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators etc. with a full range that can meet the various requirements of our customers. The company has supplied more than 500 of the most prestigious plastic, petrochemical, and metallurgical firms around the world. The company's name is widely acknowledged and is able to cover a variety of markets. The company has strong technical force, an extremely high degree of particularization, complete production equipment and an extensive testing process. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy