Pipes that work to transport liquids from one place to another, have the unique ability of getting dirty after many years. Just as your room can get messy, so too do pipes begin to gather dirt and debris from other types of junk inside them. Over time, this accumulation can turn costly with clog development and subsequent obstruction of inflow liquid or worse damage that may require to break pipes. Well this is exactly where a stainless filter screen comes in as a rescuer!

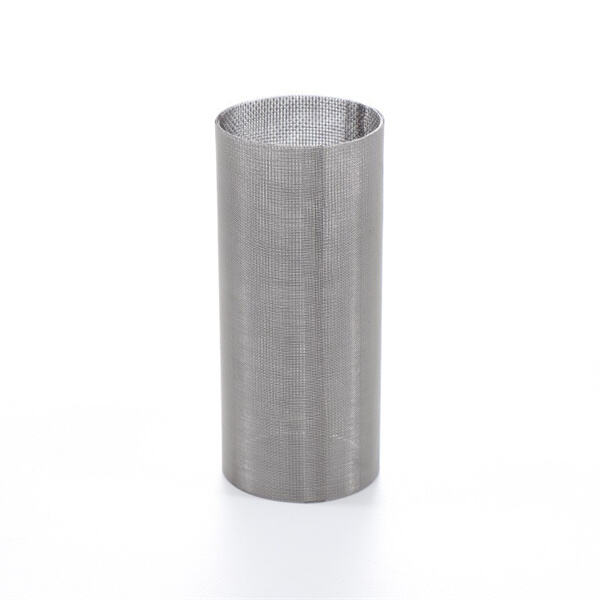

The mesh-tube filter when fitted along your pipes, acts as a shield. Holds the dirt and other debris that is in your liquid to prevent it from entering into any of your system. Clean liquid will be able to pass through your pipes. The more regularly you have your pipes cleaned, the less chance they will develop a blockage. This means that clean and operational easily avoidable issues such as clogged drain lines or sewers are greatly decreased by hiring us for pipe cleaning in Asheville NC services on a regular basis.

Besides protecting your tubes, stainless steel mesh tube helps clean another important element — the liquids passing through. For example, it is essential that the liquid used in your machinery or engines should be pure. There shall not be any dirt or even some other kind of contaminants! More importantly, the mesh tube filter is required to ensure that happens.

The filter works to stop anything else that may be floating in the liquid like sediment and other loose debris. This ranges anywhere from microscopic pieces to larger chunks of debris. These contaminants will be removed, allowing your machines to operate smoothly and efficiently without their system getting caught or damaged by any garbage within the liquid.

What makes a mesh tube filter one of the best options for your needs is that it's extremely easy to use and install. But you can set it up without special weapons and instructions. All you have to do it place the filter inside your pipes and as soonas that;s done, its working on doing what they advertised! After installation, the filter goes to work on its own. You will not have to constantly keep an eye on it or tend to it like your first born every day. It works in the background silently that gives you time to pay attention towards your other work.

The filter keeps liquids clean and pipes clear, thereby lessening the need for clogs or other issues that can result in decreased efficiency (hence repair bills). You will also be able to save some money which you use on making different changes in your house, rather than wasting it on getting all the problems fixed. This filter can totally pay for itself down the road.

Man or women, when it comes to machines — whether ones used for work, as in a factory floor context; fun (a hobby); necessity (the family SUV) or the ecologically lightest journey through your urban miles on an electric scooter— we all want them to be reliable and effective. This mesh tube filter also has a high protection layer that prevent your machineries from damaging, and chances of falling out too.

Customized services include the selection of the filter material, pore size and shape, as well as other aspects. They can also provide customized filters according to customer requirements and specifications for the extruder. The customized services allow the optimization of parameters for filtering such as structure material, filtration accuracy and more. This can improve the efficiency of filter filtration and longevity. The production is performed according to the specific requirements of the customer, and avoids excessive waste, in order to save customers money. According to the specific needs and applications of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Choose the materials that have corresponding properties, such as galvanized iron, stainless steel, etc. Create a filter design that is appropriate for the installation and operating conditions of your client.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

The extruder filter is made of high-quality metal and features a very fine size of the filter pore, which effectively removes impurities from the polymer melt and enhance the purity and quality of the polymer. The filter's structure is designed to maintain a high efficiency in filtration while the material moves through it, reducing the possibility of clogging. This improves production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. As per the specific requirements of clients and the exact specifications of the extruder specific filter solutions are available to ensure a perfect match with existing equipment and provide the most effective filtration effect. Filtration efficiency that is efficient reduces the amount of time that is lost due to the clogging of impure materials and improves productivity.

The company has a professional after-sales service team, through the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical assistance, product advice as well as cargo tracking as well as troubleshooting services. The company will contact customers regularly after the sale to find out their usage of filters and to anticipate their needs for the future. After-sales personnel is able to respond to customer issues and comments quickly by gathering the data. Additionally, feedback from customers can be passed on to the product design and production departments in order to improve the quality of products and services. The expert team determines the source of the issue, and then provides fundamental solutions to reduce the likelihood of repeating the same problem. The two are in sync and only then can we provide our customers with the highest quality customer service. This in turn can increase customer satisfaction and allow the business to increase its growth.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy