Steel welded mesh is a high-strength material that can serve a wide range of needs. {Welded Wire Mesh is a type of mesh made by welding small pieces of steel wire together at all of the intersection points in a grid formation.} The data for this mesh is very strong and serves to keep things safe. As a manufacturer of such powerful steel mesh, Xuancheng specializes in rotation aspects to protect and secure.

Welded mesh made up of countless tiny steel wires fused together through a process known as welding to form a large sheet of mesh. These are then welded and interlaced into a very strong grid structure. The other is a strong and durable grid. These features make stainless steel welded mesh widely used for fencing and barriers. It can withstand damage from collision, which means if something runs into it, it won’t break easily. One is it is resistant to cutting tools — it is very difficult to cut by. Moreover, the welded mesh is quite difficult to be scaled. This makes it perfect for security fences, as it can keep intruders out while guarding key areas of the property.

This versatility means that steel welded mesh is used in a wide variety of locations and situations. It is a vital part of the construction industry. Concrete reinforcement material is its most plum use. This makes buildings and structures much stronger, allowing them to bear heavy loads and resist damage from storms or earthquakes. The mesh will not only reinforce structures but can also create cages or barriers around constructions sites. These barriers help protect both workers and equipment from accidents or falling items.

Steel welded mesh has a wide range of applications in factories and industrial environment as well. One of its most common applications is machine guards, used to isolate workers from the moving parts of machines. It can even build cages around machines to protect people. Another type of barrier that is significant from Safety perspective are Barrier for Ground safety made from steel welded mesh, preventing mishaps in active work areas. In electronics, this mesh keeps equipment free from electromagnetic interference, so that machines don’t behave erratically.

One of the most prominent advantages of steel welded mesh is its simplicity in installation. That's due to pre-manufactured panels that arrive ready to use. So anyone can put them up, they're in standard sizes and designed to fit. Whether you are a homeowner doing a DIY project or a contractor needing many panels installed fast, these pre-made panels are an ideal choice. All the panels offered by Xuancheng are of superior quality and pass all the required standards of performance and safety.

For one's advantage, steel welded mesh of Xuancheng comes with custom designs. That means customers can specify the size, shape, and even the color of the steel welded mesh they require for their particular project. This versatility makes it an excellent choice for architects or builders who want a unique finish or configuration. There are even a range of custom designs for the steel welded mesh we produce, making it suitable for decorative features amongst other applications. This means that it not only performs a service but can also make a room more attractive.

Xuancheng Steel welded mesh is high-quality material that is ideal for outdoor use. The steel is specially treated to prevent rust and corrosion. Such properties makes it perfect for use in moisture vulnerable environments, such as near water bodies or in rainy places. Plus, the mesh doesn't get damaged by UV (ultraviolet) and extreme weather. Because it will last for many years without degrading strength or effectiveness, it is a smart investment if you are someone who needs durable materials for outdoor projects.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters, which has long been committed to the production and development of extrusion filter made from plastic and has a vast amount of technical knowledge as well as industry knowledge. The products are widely used in the fields of plastic modified granulations recycling granulations, extrusions made of films and sheets and many other applications, as well as the filtration of chemical fibers. They include filters, edging mesh, spot welded mesh, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor belt, mist eliminator wire mesh, and so on. With a wide range to meet the needs of a variety of customers. It has provided services for more than 500 known plastic, petrochemical, and metallurgical production companies across the world, offering a wide markets and an impressive influence on the brand. The company has strong technical force, high degree of particularization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

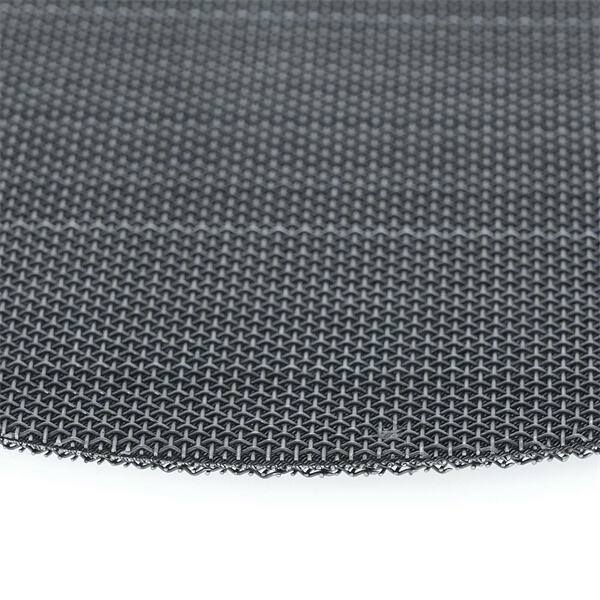

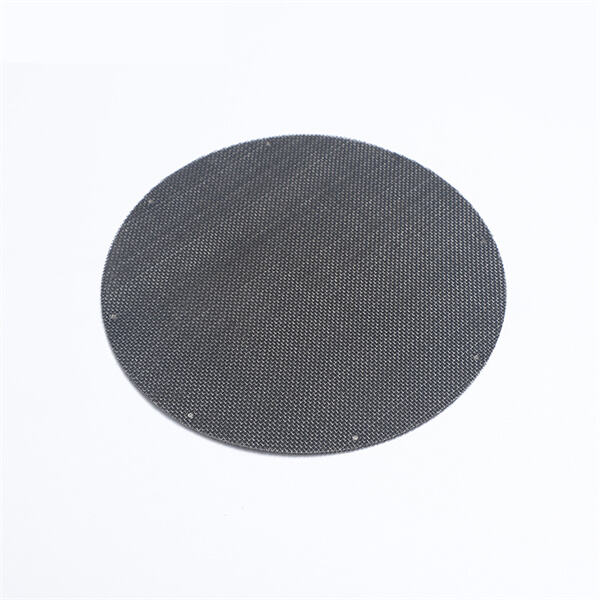

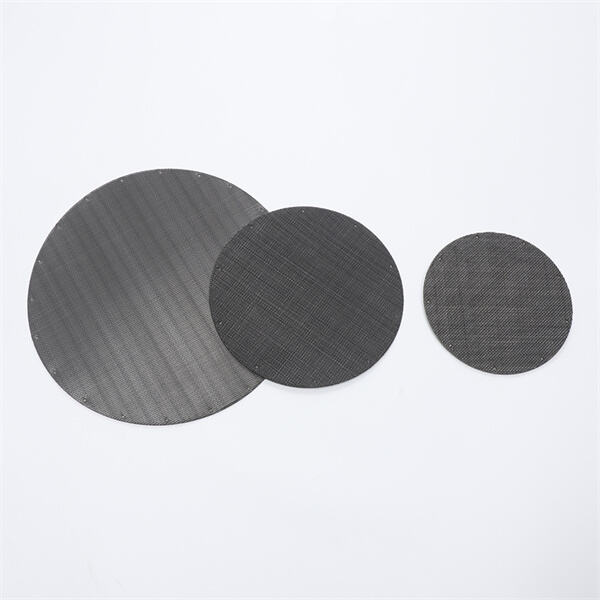

The extruder filter is constructed of high-quality metal and features a small filter pore size, which will effectively eliminate impurities from the melt of polymer as well as improve the quality and purity of the product. The filter's structure is designed to ensure continuous filtration rate while the material flows through it, reducing clogging. This improves production continuity. Metal filters are resistant to wear, corrosion and high temperatures. In accordance with the diverse requirements of the customer and the specifications of the extruder, customized filter products are available to ensure the perfect fit with existing equipment, and to provide the highest filtration effect. Effective filtration reduces downtime caused by clogging impurities, and also increases the productivity.

The company is equipped with a skilled after-sales team, utilizing the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical support, consultation on products and tracking cargo along with troubleshooting services. The company will communicate with customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the details. In addition, the feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The team of experts thoroughly investigates the cause of the issue, and then provides basic solutions to minimize the chance of repeating the same issue. Both complement each other and it is only then that we can offer our customers a high-quality after-sales experience. This in turn will strengthen customer loyalty and aid in helping the business increase its growth.

The custom service consists of the selection of filter pore size as well as the material, shape, and other aspects and will provide customized filter products according to the diverse requirements of customers and the specific specifications of the extruder. Through customized services, the structure materials, filtration precision and other aspects of the filter can be improved in order to increase its filtration efficiency and service life. The production is based on the demands of the customer and waste is minimized to lower costs. Choose materials with the most suitable properties for the requirements and needs of the client and taking into consideration the requirements for corrosion resistance, heat resistance, wear resistance etc. Design a filter structure that is appropriate for the location and usage conditions of your customer.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy