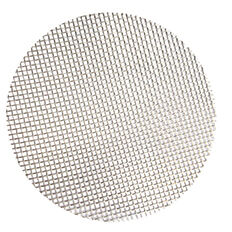

Characteristics of stainless steel metal mesh Stainless steel weave mesh is a kind of special metal wire woven by a tight pattern. This means that the wires are so close to each other that makes the mesh very tight and that is the reason why it is so strong. Xuancheng is a reputed company that's popular for manufacturing, stainless steel weave mesh. We will detail how, and why, stainless steel weave mesh is key to all types of repair and building work in this article!

Steel weave mesh, an asset with thousands of uses and is everfeasible. They are made from grade stainless steel wire mesh, which is very strong and long-lasting. That means it can survive for long periods even in harsh conditions. This strength makes stainless steel weave mesh ideal for many building and construction projects, where strength and safety are paramount.

Not only are stainless steel mesh strong but they can also be used for filtering purposes. The tightly woven pattern of mesh holds back dust and other undesirables while still allowing all the good stuff through. This ability to filter makes it extremely useful for industries such as food processing, where cleanliness is key, and chemical manufacturing, where separation of materials is necessary.

Aside from all those functional applications, stainless steel weave mesh has decorative applications as well. That shiny look and gorgeous weaving make this glimmering thread suitable to add that instant coolness to any project. Also, it is useful for architects and designers who need to build fine buildings or interiors that can be made distinctive.

In addition to that, stainless steel weave mesh is also beneficial in a roofing application. The corrosion is much bigger problem when it comes to degenerating a building in long run and it prevent the water damages as well. Stainless steel weave mesh is a construction product that can be used for roofs to keep the structure of the buildings intact and prevent expensive maintenance that could be needed if the buildings incur damage from water.

Stainless steel weave mesh has many advantages, one of which is that it is ideal for harsh environments. It’s resistant to rust and corrosion, so it won’t easily break down when exposed to water or harsh chemicals. This makes it a great option for marine usage in application like boats and docks as well as other areas where strong chemicals are used.

Customized stainless steel weave mesh JEKS 12 can be applied to architectural uses like façades and sunshades. The mesh is strong and durable, but it can always be customized to fit in perfectly with the design and look of the building. This answers architects creatively while still ensuring that their structures are secure and sensible.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

The filter in the extruder is constructed of top-quality metal, and it has tiny pores for filtering. This permits it to eliminate impurities and improve the purity and quality of the polymer. The structure of the filter is designed to ensure that the material flow remains stable in filtration throughout its passage, reducing clogging and improving production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. Filter products that are custom-designed can be found to meet the requirements of different customers, and to match the equipment. A high-performance filtration system reduces the amount of delays caused by clogging of impurities and boosts the productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters, which has long been committed to the production and development of extrusion filter made from plastic and has a vast amount of technical knowledge as well as industry knowledge. The products are widely used in the fields of plastic modified granulations recycling granulations, extrusions made of films and sheets and many other applications, as well as the filtration of chemical fibers. They include filters, edging mesh, spot welded mesh, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor belt, mist eliminator wire mesh, and so on. With a wide range to meet the needs of a variety of customers. It has provided services for more than 500 known plastic, petrochemical, and metallurgical production companies across the world, offering a wide markets and an impressive influence on the brand. The company has strong technical force, high degree of particularization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

The company is equipped with a skilled after-sales team, utilizing the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical support, consultation on products and tracking cargo along with troubleshooting services. The company will communicate with customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the details. In addition, the feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The team of experts thoroughly investigates the cause of the issue, and then provides basic solutions to minimize the chance of repeating the same issue. Both complement each other and it is only then that we can offer our customers a high-quality after-sales experience. This in turn will strengthen customer loyalty and aid in helping the business increase its growth.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy