Stainless steel welded wire mesh is a unique type of wire used in a wide variety of necessary and important applications. It consist small pieces of stainless steel that joint together or welded together to form a strong metal mesh. Galvanized wire mesh is highly favored thanks to its numerous benefits. Xuancheng is a competitive manufacturer expert in premium 316 stainless steel welded wire mesh. In this article, we will explore the advantages of this wire mesh, its various applications in different industries, its reliability, how it compares to other types of wire mesh, and how to select the right wire mesh for your needs.

In fact there are many great benefits of stainless steel welded wire mesh that make it an ideal option for a number of applications. Another benefit is that it is extremely strong and long-lasting. Wire mesh can withstand harsh weather, including rain, snow and wind. It also features resist rust and corrosion, so it will not break down or weaken easily. Due to this strength and durability, it makes an ideal material for applications in which a robust one is needed.

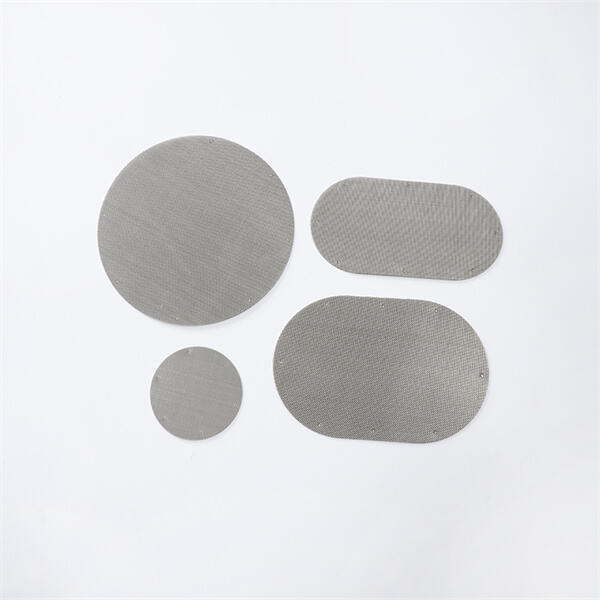

Stainless steel welded wire mesh is also used for its versatility. In other words, you can get it into all shapes and sizes, and so it can be used in many different ways based on the needs. As an example, it is frequently found in the building and industrial sectors, as well as in the creation of food and other items. This adaptable nature has made it popular among builders, farmers, and food producers.

A stainless steel welded wire mesh is available in several various types and has several applications. In the construction sector, it is commonly employed to strengthen concrete. That means, it can either strengthen the concrete or aid in stabilization of the structures i.e walls, bridges. It is also commonly among the materials used for fencing and gating, serving as a significant barrier against intruders into secured zones and helping to ensure that larger animals are kept properly contained.

This allows stainless steel welded wire mesh to act as a barrier in agriculture. It acts to deter pests, including insects or small animals, from eating crops and livestock. As such, this is very pertinent for farmers who wish to safeguard their flora and fauna. Moreover, it is used to make cages and enclosures, which allows animals to keep them safe and secured.

It is used in the creation of food products, such as cheese and other dairy items in the food industry. It is also used in restaurants and other food service establishments for creating safe and clean preparation and storage areas. Making sure of the safety and hygiene of food is of utmost importance which is what this wire mesh strives to do.

Stainless steel welded wire mesh is one of the more durable and dependable migrations in terms of mesh types. There are various kinds of other wire mesh available in the market like galvanized wire mesh, aluminum wire mesh, etc. Stainless steel, on the other hand, is much more durable and resistant to rust or corrosion.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters which has been dedicated for many years to the development and production of plastic extrusion filters, and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of sheets, films and other industrial processes, as well as the filtration of chemical fiber spinning and other industries. They comprise filter mesh, edging mesh spot welded mesh, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor mesh belt wire mesh mist eliminator and so on., with a complete collection to meet the needs of different customers. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great brand influence. The company is equipped with strong technical strength and has the most advanced production equipment, as well in a complete test method. The company has been accredited to ISO9001:2015 to ensure a stable and reliable product.

The company has a professional after-sales team, utilizing the telephone, online customer support along with social media and other contact methods, can efficiently provide customers with technical support, product consultation as well as cargo tracking and troubleshooting, among other services. The company will contact customers regularly after the sale to find out their current usage of filters and to anticipate their needs for the future. By collecting customer feedback and problems encountered in the service after sales department, it is able to respond quickly and offer a prompt respond. Furthermore, feedback is also passed back to product design and production departments to enhance products and services. The team of experts thoroughly investigates the cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. Both complement each other and only then can we offer our customers a high-quality customer service. This improves customer loyalty and assist the company to expand.

The filter of the extruder is made from high-quality steel and features small pores for filtering. This helps to eliminate impurities, and increase the purity and quality of the polymer. The filter's structure is designed to ensure constant filtration efficiency while the material flows through it, which reduces the likelihood of clogging. This helps to ensure that the production process is continuous. Metal filters have a high resistance to wear, corrosion and high temperatures. Filter products can be customized to meet the requirements of various customers and to be compatible with the equipment. Filtration efficiency that is efficient reduces the time it takes to repair due to blockage of impurities, and also increases the productivity.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy