Learn about fine metal mesh screen It sounds a bit bizarre, almost like sewing something you would wear… but it is actually a different kind of material made up of tiny metal wires that are connected to each other in a particular way. Xuancheng is a famous company in China that is known for making premium metal wire cloth for several uses. So, now we are going to find out the amazing things this material is capable and why it is so important!

Metal wire cloth is formed by the weaving of metal wires to make a fabric that looks identical to a mesh. They have used a unique weaving technique, which means it is very strong that it will withstand any robust conditions without breaking or even damaging. Xuancheng metal wire cloth materials are used of stainless steel, this is a type of metal that water could not rust it or damage. All this means is that it can be considered to be used in many environments without having to worry about it being worn out prematurely. The metal wire cloth can last for years with proper care and maintenance, so it is one of the best investments you can make.

Metal wire fabric also is used for filtering! It is a great decorative material as well. This characteristic look and texture make it an excellent material for buildings and architectural details. In addition to facades, cladding and decorative screens. There are many patterns and finishes available within the Xuancheng range, with so much versatility you should be able to find the perfect type of steel woven wire mesh pattern or finish to suit anywhere in your next design.

It can be difficult to cleave such small particles, sometimes the form is very particular, or strangely shaped. If this sounds similar to what your processing plant is also going through, metal wire cloth can offer a solution. Xuancheng metal wire cloth is a fine mesh that can gaol nanoparticles that are only two or three microns in size, which is very penurious. Its ability to sieve and segregate at a variety of industries application, such as pharmaceuticals, food processing, and mining makes it an effective vibration equipment solution. All of these are challenging and time-consuming, but with this material they can be made easier and faster.

Metal wire meshes are prevalent in factories and industrial areas, not only for their strength and utility but there is a large list of causes to use them. One of the reasons it works so well for this is because they can withstand high heat and pressure without breaking down. Metal wire cloth from Xuancheng is heat resistant, making it the perfect choice for metalworking or chemical production processes that require extensive amounts of both heat and pressure for manufacturing.

One more key benefit of the metal wire cloth is its simple cleaning process. The mesh construction makes to very easy to clean and clear off any trapped particle. Especially in industries that demand an extreme level of hygiene, food processing and pharmaceutical industries. A sanitary warehouse will help our items to be safeguarded and in accordance with health regulations.

Metal wire cloth is a versatile material that people use in many different industries. For example, it is used by the automotive sector in airbag filters and a catalytic converter (part of the car that reduces emissions from the vehicle). Wire-mesh iron design is utilized for the ornamental purpose as well as for reinforcement to develop a structure in the building profession. For the aerospace sector, it finds use in engine filters and insulation to ensure safe operation of airplanes at high altitudes.

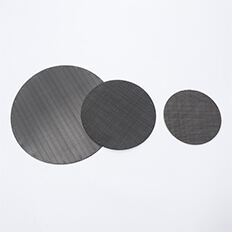

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

Customized services include the selection of filter material dimensions, pore size and shape, as well as other elements. They also can provide customized filters according to customer needs and extruder specifications. With customized services, the structure as well as the material, filtration efficiency and other parameters of the filter can be adjusted, so as to improve its efficiency in filtration as well as the life of the filter. The process is designed in accordance with the needs of the client, thus avoiding excessive waste, in order to reduce the cost of customers. Choose the materials with proper properties that meet the demands and requirements of the customer and taking into consideration the needs in terms of heat resistance, wear resistance etc. Based on the usage setting and the conditions of installation, design a reasonable filter structure, for example types of plates, wound types or cylindrical, for instance.

The company has a professional after-sales service team, through the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical assistance, product advice as well as cargo tracking as well as troubleshooting services. The company will contact customers regularly after the sale to find out their usage of filters and to anticipate their needs for the future. After-sales personnel is able to respond to customer issues and comments quickly by gathering the data. Additionally, feedback from customers can be passed on to the product design and production departments in order to improve the quality of products and services. The expert team determines the source of the issue, and then provides fundamental solutions to reduce the likelihood of repeating the same problem. The two are in sync and only then can we provide our customers with the highest quality customer service. This in turn can increase customer satisfaction and allow the business to increase its growth.

Yangzhou Xuancheng Filter Screen Co., Ltd., a manufacturer of extruder screens, has been dedicated to the design and manufacture of plastic extrusion filter for a long time. They have built up an extensive amount of technical know-how and have gained experience in this business. They are extensively used in the manufacture of granulations that are modified with plastic, recycling granulations, extrusions made of films and sheets and many more along with filters for spinning chemical fibers. There is a variety of products available, such as filters, edging meshes, spot-welded meshes stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators etc. with a full range that can meet the various requirements of our customers. The company has supplied more than 500 of the most prestigious plastic, petrochemical, and metallurgical firms around the world. The company's name is widely acknowledged and is able to cover a variety of markets. The company has strong technical force, an extremely high degree of particularization, complete production equipment and an extensive testing process. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy