Spark, safety and protect…We can still analyse these few words simply to understand certain terms in welding screens. To discover just how dangerous a few sparks can be, have a look at the video When people are Doing welding all those sparks(Coming out). That is where when people utilize these little machines with wreck welding screens. These screens ensure the safety of all while they do their work.

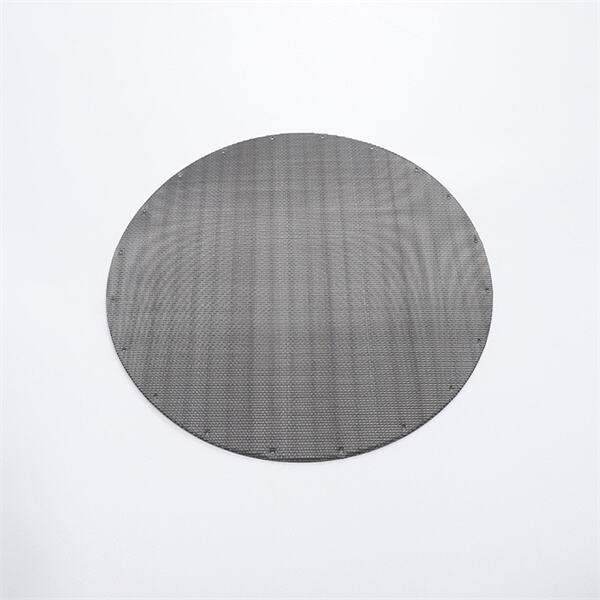

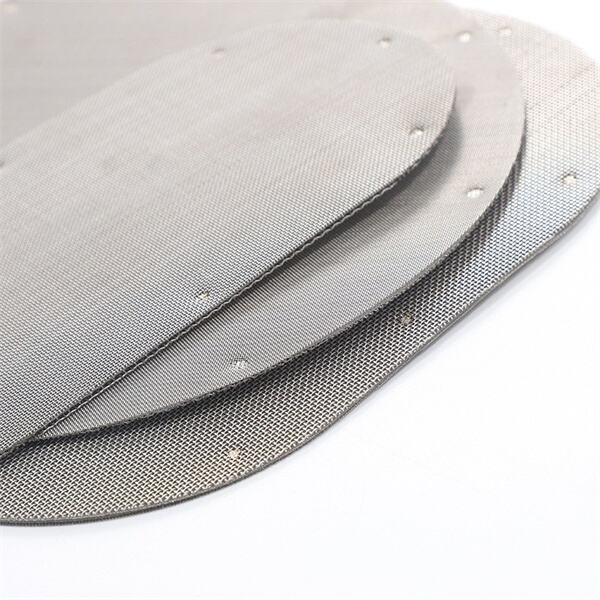

Designed to prevent sparks from flying out and burning the body Spot welding screens.AddWithValue ( [KeepAlive] ) And are carefully constructed to withstand the high temperatures produced from welding and resist breakage from any projectiles of debris during a job. Available in sizes to meet individual needs locate the one that fits your workspace better.

When welding, people will use very high heat and electricity to fuse two pieces of metal together. This generates high heat and sparks which can cause serious injuries to nearby people. These sparks can be dangerous, so stainless steel screen wires are important because they protect people and objects from these harmful embers. They are there so no one gets hurt, or something sets on fire again.. (Really unsafe)

When choosing a location to use for spot weld screens, you must take into account the scale of your area that really needs protection. Select a screen that fits well in the area or space you are working and(Note): Additionally, you have to select a screen that is constructed of one of the most advantageous products for your work. PVC, a type of plastic: while other screens are made from fiberglass which is sturdy and can cope with high heat.

These types of stainless filter screens must be maintained to ensure that they continue working effectively in order for the environment and its workers or objects located nearby protected from sparks. Always inspect your display screen for damage or wear and tear. You have to solve when you see real-time issues. Previous imageLarger viewPDFEmailPrintPreviewNext ImageIt is also critical to regularly clean your screen, wiping away dirt or debris that may have accumulated. This helps make the screen function better, as well as keeping everyone else out of your way safely and securely.

So you can follow a few things to make your spot welding screen even better. For instance, locate the screen closer to welding area for more spark coverage Additionally, your coverage may be widened over a larger area by using more than one screen as part of the barrier. Moreover, you can use different types of screens for various tasks so as to make your work quicker and easier.

Customized services can include the choice of the filter material along with the pore size and shape and other elements. They also can provide custom-designed filters based on customer requirements and specifications for the extruder. Customized services allow for the optimization of parameters for filtering like structure and material, filtration precision and many more. This can improve the filter's filtration efficiency and life. The production is performed according to the actual needs of the customers, while avoiding unnecessary waste in order to help customers reduce costs. According to the specific needs and scenarios for customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have similar properties, like stainless steel, galvanized iron or galvanized iron. Create a filter design that is appropriate for the installation and operating conditions of your customer.

Yangzhou Xuancheng Filter Screen Co., Ltd. is a reputable manufacturer of extruder filter, which has been dedicated for many years to the creation and development of extrusion-based plastic filters and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other products, as well as the filtering of chemical fiber spinning and other industries. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt, wire mesh mist eliminator, etc. With a wide assortment to meet the demands of various clients. The company has offered services to more than 500 famous plastic, petrochemical and metallurgical production companies across the globe, and has a broad market coverage and strong impact on brand image. The company has a strong technological force, high degree of specialization, complete production equipment and an extensive testing process. The company has been accredited with ISO9001:2015 to ensure the stability and reliability of its product.

The company has a knowledgeable after-sales service team, through telephone, online customer service along with social media and other ways of communication, it is able to quickly provide customers with technical support, product consulting and tracking cargo and troubleshooting, among other services. The company will contact customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the data. Furthermore, feedback is also fed back to product design and production departments to enhance the quality of products and services. The experienced team analyzes the root cause of the problem and provides basic solutions to minimize the chance of repeating the same problem. When the two are in harmony, will we be able to provide customers with an exceptional after-sales customer experience. This strengthens customer loyalty and promotes the long-term development of the enterprise.

The filter in the extruder is made of premium metal with very fine pores. This helps to eliminate contaminants and enhance the quality and purity of the polymer. The structure of the filter is designed to ensure a high efficiency in filtration while the material is flowing through it, thus reducing the possibility of the likelihood of clogging. This increases the efficiency of production. The metal filter is highly resistant to resistance to corrosion, wear and high temperatures. Customized filter products are available to satisfy the requirements of different clients, and also to fit with the equipment. A high-performance filtration system decreases the time lost to interruptions caused by the accumulation of impurities and boosts the productivity.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy