الشرارة، السلامة والحماية... يمكننا دائمًا تحليل هذه الكلمات القليلة ببساطة لفهم بعض المصطلحات في شاشات اللحام. لاكتشاف مدى خطورة الشرارات الصغيرة، شاهد الفيديو عندما يقوم الناس بلحام وتنطلق الشرارات (المخرجة). هذا يحدث عندما يستخدم الناس هذه الآلات الصغيرة مع شاشات اللحام. هذه الشاشات تضمن سلامة الجميع أثناء قيامهم بعملهم.

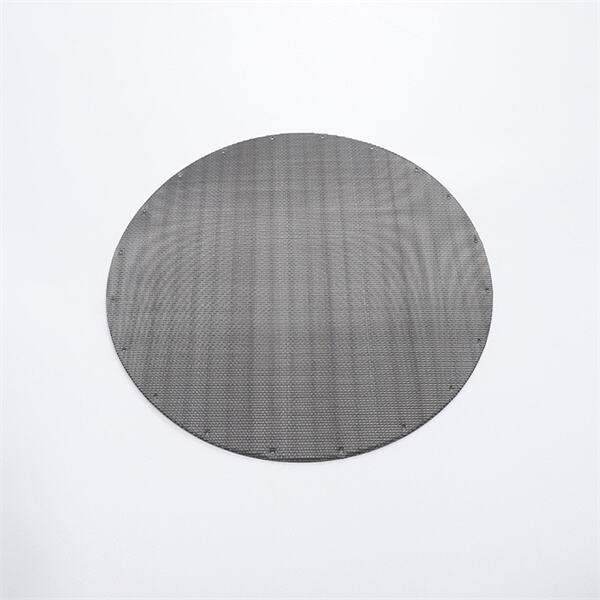

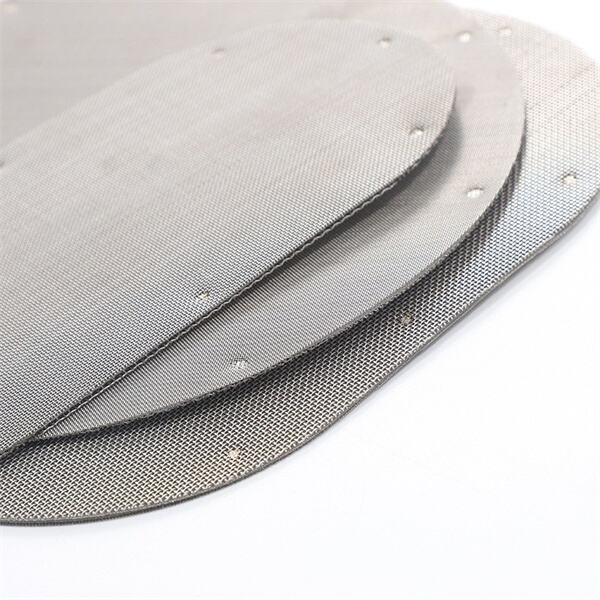

صممت لمنع الشرارات من التطاير وإحراق الجسم. شاشات اللحام بالنقاط:AddValue ([KeepAlive]) وتُصنع بدقة لتحمل درجات الحرارة العالية الناتجة عن اللحام ولمقاومة الكسر بسبب أي حطام طائر أثناء العمل. متوفرة بأحجام لتلبية الاحتياجات الفردية، ابحث عن الحجم الذي يناسب مساحتك للعمل بشكل أفضل.

عندما يقوم الناس باللحام، يستخدمون حرارة وكهرباء مرتفعة لدمج قطعتين معدنيتين معًا. هذا يولد حرارة وشرارات عالية قد تسبب إصابات خطيرة للأشخاص القريبين. يمكن أن تكون هذه الشرارات خطرة، لذلك شبكة شاشة فولاذية مقاومة للصدأ هي مهمة لأنها تحمي الأشخاص والأشياء من هذه الشرر الضار. وجودها هو لضمان ألا يتأذى أحد، أو أن تشتعل النار مرة أخرى. (غير آمن للغاية)

عند اختيار مكان لاستخدامه لشاشات اللحام النقاطي، يجب عليك أخذ نطاق المنطقة التي تحتاج حقًا إلى الحماية في الاعتبار. اختر شاشة تناسب جيدًا المنطقة أو المساحة التي تعمل فيها و(ملاحظة): بالإضافة إلى ذلك، يجب عليك اختيار شاشة مصنوعة من أحد المنتجات الأكثر فائدة لعملك. البولي فينيل كلورايد (PVC)، نوع من البلاستيك: بينما تُصنع شاشات أخرى من الزجاج المقوى الذي هو قوي ويمكنه التعامل مع درجات الحرارة العالية.

هذه الأنواع من شاشة ترشيح من الفولاذ المقاوم للصدأ يجب الحفاظ على الشاشات لضمان استمرار عملها بكفاءة من أجل حماية البيئة والعاملين أو الأشياء القريبة من الشرر. فحص شاشتك دائمًا لأي تلف أو اهتراء. يجب عليك حل المشكلات الفعلية التي تظهر في الوقت الحقيقي. الصورة السابقة - عرض أكبر - PDF - بريد إلكتروني - طباعة - معاينة - الصورة التالية. كما أنه من الضروري تنظيف الشاشة بانتظام، ممسحاً عنها الأوساخ أو الرواسب المتراكمة. هذا يساعد في تحسين أداء الشاشة، بالإضافة إلى الحفاظ على سلامة الجميع وحمايتهم.

لذلك يمكنك اتباع بعض الأمور لجعل شاشة اللحام الخاصة بك أفضل. على سبيل المثال، ضع الشاشة أقرب إلى منطقة اللحام للحصول على تغطية أكبر ضد الشرر. بالإضافة إلى ذلك، يمكن توسيع التغطيتك على منطقة أوسع باستخدام أكثر من شاشة واحدة كجزء من الحاجز. علاوة على ذلك، يمكنك استخدام أنواع مختلفة من الشاشات للأعمال المختلفة مما يجعل عملك أسرع وأسهل.

يمكن أن تشمل الخدمات المخصصة اختيار مادة الفلتر إلى جانب حجم وشكل المسامات والعناصر الأخرى. كما يمكنها تقديم فلاتر مصممة خصيصًا بناءً على متطلبات ومواصفات العميل للماكينة الخلاطية. تتيح الخدمات المخصصة تنظيم معايير الترشيح مثل البنية والمادة، دقة الترشيح وغيرها الكثير. يمكن لهذا الأمر تحسين كفاءة ترشيح الفلتر وعمره الافتراضي. يتم الإنتاج وفقًا لاحتياجات العملاء الفعلية، مع تجنب الهدر غير الضروري لمساعدة العملاء على تقليل التكاليف. وفقًا للاحتياجات والسيناريوهات الخاصة بالعملاء، مع الأخذ في الاعتبار المتطلبات الفريدة مثل مقاومة التآكل، مقاومة درجات الحرارة العالية، مقاومة الاحتكاك على سبيل المثال. اختر المواد التي تمتلك خصائص مشابهة، مثل الفولاذ المقاوم للصدأ، الحديد المغلفن أو الحديد المجلفن. قم بتصميم فلتر مناسب لظروف التركيب والتشغيل الخاصة بعميلك.

شركة Yangzhou Xuancheng Filter Screen Co., Ltd. هي شركة تصنيع موثوقة لفلتر المُضغّات، وقد خصصت جهودها لسنوات عديدة لتطوير وابتكار فلاتر بلاستيكية بالاستناد إلى عملية التشكيل بالإخراج، ولديها تراكم تقني عميق ومعرفة واسعة في الصناعة. يتم استخدام هذه الفلاتر بشكل واسع في إعادة تدوير حبيبات البلاستيك، وإنتاج الأفلام والألواح وغيرها من المنتجات، بالإضافة إلى ترشيح صناعات مثل غزل الألياف الكيميائية. تتضمن منتجاتها فلاتر، شبكات حدودية، شبكات مقاومة تم لحامها بالنقاط، أحزمة شبكة فولاذية غير قابلة للصدأ ذات تعزيز أوتوماتيكي، وأحزمة ناقلة، وشبكات إزالة الضباب السلكية وما إلى ذلك. توفر الشركة مجموعة واسعة من المنتجات لتلبية احتياجات العملاء المختلفين. قدّمت الشركة خدماتها لأكثر من 500 شركة معروفة في مجالات الإنتاج البلاستيكي والنفطي والميتاليورجي حول العالم، ولديها تغطية سوقية واسعة وتأثير قوي على صورة العلامة التجارية. تتمتع الشركة بقوة تقنية كبيرة، ودرجة عالية من التخصص، ومعدات إنتاج كاملة وعملية اختبار واسعة. كما حصلت الشركة على شهادة ISO9001:2015 لضمان استقرار وموثوقية منتجاتها.

تتمتع الشركة بفريق خدمة ما بعد البيع المتمرس، حيث يمكنها من خلال الهاتف والخدمة العملاء عبر الإنترنت فضلاً عن وسائل التواصل الاجتماعي وغيرها من طرق الاتصال، تقديم الدعم الفني والاستشارات المتعلقة بالمنتجات وتتبع الشحنات وإصلاح الأعطال بين الخدمات الأخرى بشكل سريع للعملاء. ستقوم الشركة بالتواصل مع العملاء بشكل دوري بعد الشراء لمعرفة استخدامهم الحالي للفلاتر والتوقعات المستقبلية. يستطيع فريق خدمة ما بعد البيع التعامل بسرعة مع شكاوى العملاء والملاحظات من خلال جمع البيانات. بالإضافة إلى ذلك، يتم إرسال التغذية الراجعة أيضًا إلى أقسام تصميم المنتجات والإنتاج لتحسين جودة المنتجات والخدمات. يقوم الفريق ذو الخبرة بتحليل السبب الجذري للمشكلة ويقدم حلول أساسية لتقليل فرصة تكرار نفس المشكلة. عندما يكون هناك تناغم بين الاثنين، سنتمكن من تقديم تجربة استثنائية للعملاء في خدمة ما بعد البيع. وهذا يعزز ولاء العملاء ويدفع نحو تطوير مستدام للشركة على المدى الطويل.

يُصنع المرشح في الجهاز الخازوق من معدن عالي الجودة ذو مسام دقيقة جدًا. هذا يساعد على القضاء على الشوائب وتحسين جودة ونقاء البوليمر. تم تصميم هيكل المرشح لضمان كفاءة عالية في التنقية أثناء مرور المادة من خلاله، مما يقلل من احتمالية انسداد المرشح. المعدن المستخدم في المرشح مقاوم للغاية للتآكل، الاحتكاك والدرجات العالية من الحرارة. هناك منتجات مرشحات مخصصة لتلبية متطلبات العملاء المختلفين وللتوافق مع المعدات. يعمل نظام تنقية عالي الأداء على تقليل الوقت الضائع بسبب الانقطاعات الناجمة عن تراكم الشوائب وزيادة الإنتاجية.

جميع الحقوق محفوظة © شركة يانغتشو شوانشينغ لصناعة الشاشات المرشحة المحدودة - سياسة الخصوصية