Stainless steel woven wire mesh is a valuable tool capable of performing many necessary functions. This is a very useful type of mesh that is used by many people, for a variety of reasons. That is why Xuancheng wants young readers to know about stainless steel woven wire and how it can help with a variety of tasks!

Stainless Steel Woven Wire Mesh: Benefits Of Using The Stunning Tool One of the main benefits is that it is super strong, remaining intact for a long time without breaking or getting damaged. What this means is, when you use it you can expect it to work well for a long time. And because this mesh does not rust or get harmed by water, it wouldn't be affected even if I spilled some sweat onto it. This makes it a great option for outdoor projects or in areas that might be moist and humid, where other metal types can be wrecked within a short time. Stainless steel mesh is needed to many people because of its strong and anti-ruin.

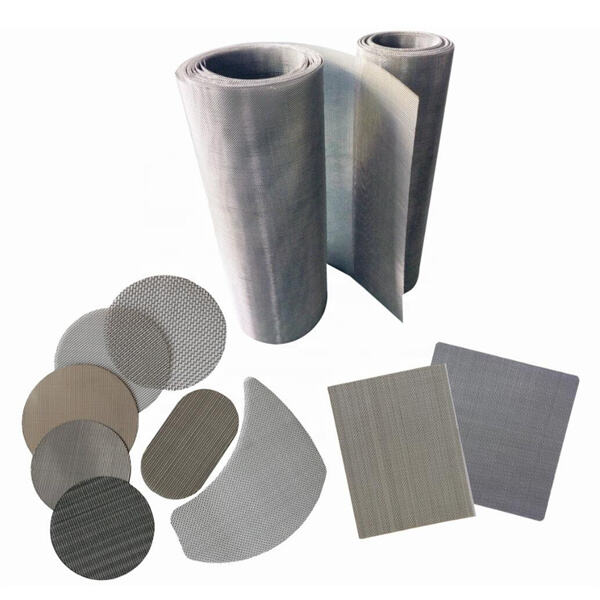

There is vast scope of applications for 304 stainless steel woven wire mesh. One case that it can be used as a barrier is a safety barrier when there are stored materials that should not be touched by humans or animals. The table will open in a new tab, which is helpful especially for places like farms or gardens where you need to guard any plants or livestock you have. Moreover, mesh of this type can be used to filter liquids or gases and to exclude all things except specific items. This is extremely beneficial in multiple sectors, like water treatment or air filtration. Besides serving as a support for plants, stainless steel woven wire mesh can support the growth of plants. The same educategory, obviously, is quite different in an educategory of other uses that people need to achieve it, including art projects, building materials, or safety equipment.

Xuancheng understands that stainless steel woven wire mesh has many advantages over other types of mesh. For one, it’s far stronger than plastic mesh that can break or wear away if you breathe too deeply. Plus, unlike some other materials, it doesn’t degrade so quickly in sunlight. This makes it more reliable for outdoor use. Also, stainless steels woven wire mesh is more robust than other metals mesh, for example, aluminum or copper. It has excellent resistance to rust and corrosion, which means that it can be used in a wide variety of environments, from wet environments to areas with high heat. This durability makes it a go-to for many users who want a long-term solution.

There are a few key considerations to keep in mind when selecting the best stainless steel woven wire mesh for your project. First, think about the size of the mesh holes — this will dictate what can and can't pass through. This is for when you filter or fence, for example. Then, you may want to consider wire guage. Thicker wire will be more robust and able to withstand wear and tear, making it better for heavy usage. Other things to consider could be the grade of stainless steel used that determines its strength and rust resistance, wire finish that can influence its appearance and the style of weaving that can alter the way the mesh works.

Xuancheng has a wide range of stainless steel woven wire mesh for your needs! We throw everything into producing the best high-quality products that we can with a small team of specialists. We select the finest quality materials available and employ state-of-the-art methods to manufacture meshites to ensure that they are robust, durable and efficient in a variety of applications. We have dissimilar types of mesh for whatever project you have, be it a fence, filter, support structure, etc.

The company has a knowledgeable after-sales team, utilizing phone, online customer service, social media and other methods of contact, they can offer customers quick technical assistance, product advice as well as cargo tracking as well as troubleshooting services. After the items are purchased, regular communication with the buyer is carried out to understand the usage of their filters as well as the future requirements and expectations. By collecting customer feedback and issues encountered in the service after sales department, it is able to respond promptly and provide prompt treatment or respond. Additionally the information is relayed back to the design or production team to aid in the constant improvement of products and services. The expert team analyzes the root cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. When the two are in harmony, can we provide customers with an excellent after-sales service experience, which in turn enhances customer loyalty and aids in the development of the enterprise.

The filter in the extruder is constructed of top-quality metal, and it has tiny pores for filtering. This permits it to eliminate impurities and improve the purity and quality of the polymer. The structure of the filter is designed to ensure that the material flow remains stable in filtration throughout its passage, reducing clogging and improving production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. Filter products that are custom-designed can be found to meet the requirements of different customers, and to match the equipment. A high-performance filtration system reduces the amount of delays caused by clogging of impurities and boosts the productivity.

Customized services involve the selection of filter material, pore size and shape in addition to other aspects. They can also provide personalized filters to meet customer specifications and requirements for extruders. With the help of customized services, structure, material, filtration accuracy and other parameters of the filter can be improved in order to increase its efficiency at filtration and prolong its service life. The process is designed according to the specific requirements of the customer, and avoids unnecessary waste, so as to save customers money. Choose the materials with most suitable properties for the requirements and needs of the client, taking into account the needs for heat resistance, corrosion resistance, wear resistance etc. Choose a filtering structure that is appropriate for the location and usage conditions of your client.

Yangzhou Xuancheng Filter Screen Co., Ltd., an extruder screen manufacturer is devoted to the design and manufacture of plastic extrusion filter for a long time. They have amassed vast amounts of technical expertise and know-how in the field. They are extensively used in the fields of plastic modified granulations recycling granulations, extrusions made of films and sheets and many more in addition to filters for spinning chemical fibers. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor belt, wire mesh mist eliminator, and so on. They offer a comprehensive collection to meet the needs of a variety of customers. The company has served over 500 well-known plastic, petrochemical and metallurgical companies around the world. The brand is well known and it is able to cover a variety of markets. The company has strong technical strength and possesses specialized production equipment, as well with a comprehensive testing process. The company has been accredited to ISO9001:2015 to ensure a stable and reliable product.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy