We are happy to provide s for any and all your filtration requirements here at Xuancheng. These stainless mesh filters inserts work great when you need a stronger filter to survive hard use. These are what you use to turn all the stuff that just winds up in your energy products into clean liquids and gases.

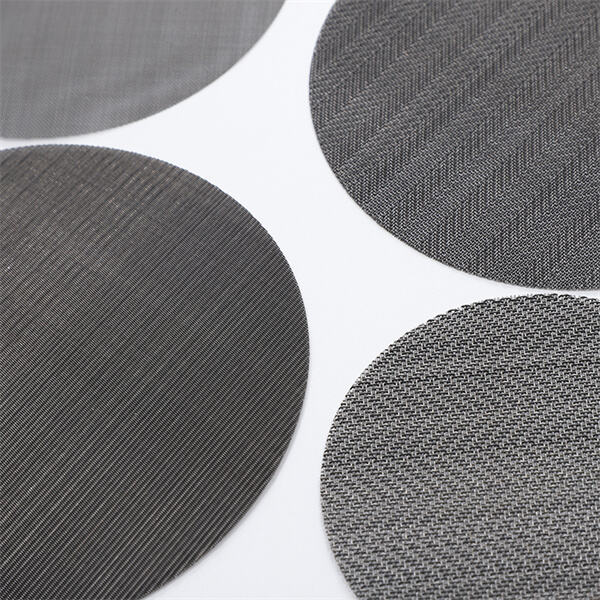

The beauty of metal filter discs is their sturdiness and robustness. Metal filters Metal is very strong, so it could be helpful if you have a metal filter — they generally last quite. Its resistance to breaking down in high heat, and with strong chemicals. Thus, for a selection of filters that you know will do their business efficiently then either altogether foul circumstances in factories and industries they are the ideal.

Metal filter discs have some of the best positive things going for them, opposed to other filters. It filters extremely well, capturing all the little bits and pieces to prevent it passing through alongside your liquid. This is crucial in several types of applications, such as food or beverage production (not a single speck of dirt/foreign particle can be around anything edible). Furthermore, metal filter discs are durable and strong making them ideal for harsh environments where they will not compromise their filtering abilities. They are easy to clean and maintain, making them a convenient option for many applications.

Basic Cleaning of Metal Filter Discs When prompted to clean them, simply remove the filter from your device. After that, rinse it with water and soap to get rid of any dirt or noise. Remember to dry it well before re-inserting into the system after washing. This method of cleaning is the best and also assists in getting your filters back to work yet again for a good amount of time. Routine cleaning of your filters will help to maintain their performance and prolong the life of HEPA style cabin air filter.

Metal filter discs perform exceptionally well. These filters provide high flow rates and the best filtration. That would make them good for letting a lot of liquid or gas through while keeping things clean. They can be applied to various applications including Food & Beverage, Chemical Processing and many other industries. From liquids to gases and other types of fluids, metal filter discs deliver consistent performance whether you are filtering water for a cooling process or industrial operations.

The company has a professional after-sales team, utilizing the telephone, online customer support along with social media and other contact methods, can efficiently provide customers with technical support, product consultation as well as cargo tracking and troubleshooting, among other services. The company will contact customers regularly after the sale to find out their current usage of filters and to anticipate their needs for the future. By collecting customer feedback and problems encountered in the service after sales department, it is able to respond quickly and offer a prompt respond. Furthermore, feedback is also passed back to product design and production departments to enhance products and services. The team of experts thoroughly investigates the cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. Both complement each other and only then can we offer our customers a high-quality customer service. This improves customer loyalty and assist the company to expand.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the development and production of extrusion filters made of plastic, and has profound technical accumulation and experience in the industry. The products are extensively used in plastic modified granulation recycling extrusion of sheets, films and other types of industries along with the filtration of chemical fiber spinning and other industries. They include filters, edging mesh spot-welded mesh, automatic switching stainless steel mesh belt, reinforced mesh, conveyor mesh belt wire mesh mist eliminator etc. It offers a full assortment to meet the demands of various customers. It has supplied services to over 500 famous plastic, petrochemical and metallurgical production enterprises around the globe, and has a broad market coverage and a strong brand influence. The company is equipped with strong technical strength and has specialized production equipment, as and a full testing system. It has been awarded the ISO9001:2015 quality management system certification to ensure stable and reliable product quality.

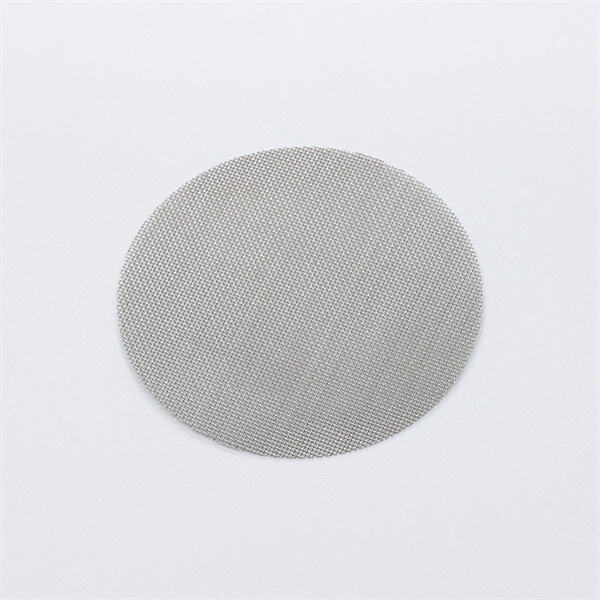

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

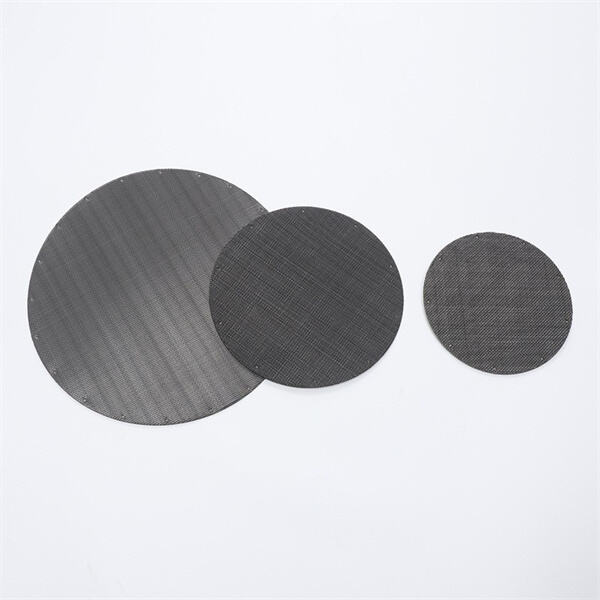

Customized services can include the choice of the filter material along with the pore size and shape and other elements. They also can provide custom-designed filters based on customer requirements and specifications for the extruder. Customized services allow for the optimization of parameters for filtering like structure and material, filtration precision and many more. This can improve the filter's filtration efficiency and life. The production is performed according to the actual needs of the customers, while avoiding unnecessary waste in order to help customers reduce costs. According to the specific needs and scenarios for customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have similar properties, like stainless steel, galvanized iron or galvanized iron. Create a filter design that is appropriate for the installation and operating conditions of your customer.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy