Did you ever see a plastic bag or straw? These materials are extruded, not molded. During the extrusion process, raw plastic is forced through a machine in order to create shapes such as bags, straws, and many other common plastic items. But sometimes the plastic can collect little bits of dirt or other stuff you don't want on your body and that's no good. And this is where screen pack filters can save the day.

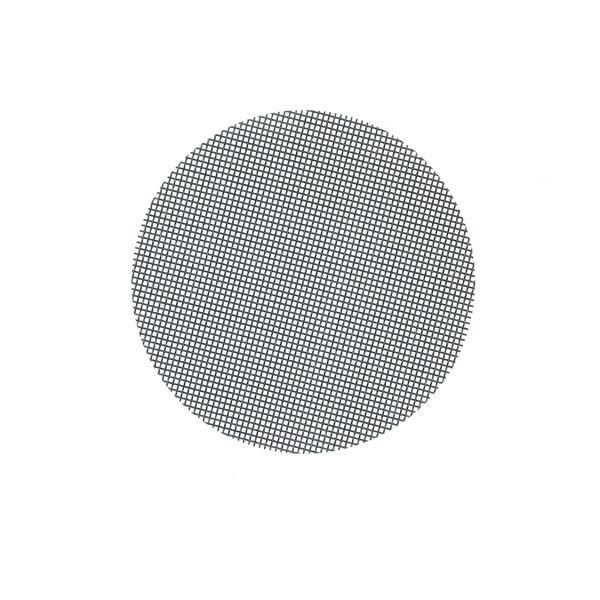

Screen pack filters are special tools used during the extrusion process They ensure that the plastic is clean before it is formed. If you need a screen pack filter that is high in quality, Xuancheng is a company that does a great job making its products. These filters are basically stacks of mesh screens, a lot of very finely meshed screens stacked one over another, sort of like layers of cake. Together, the three layers trap the dirt and impurities that may exist in the plastic prior to molding it into its final form. This ensures good quality plastic.

This is much cleaner of the plastic than one would achieve by filtering through a grid, rather than through the pack screen. Removing impurities such as dust or small pieces of metal or other foreign materials is crucial before the plastic is melted down to be formed. Screen pack filters with several layers work better than the mesh filter. This allows it to trap a larger amount of dirt and undesirable particulates, which enhances the plastic’s overall quality.

The screen pack filters are good because they ensure that the plastic is always good quality. The filter removes contaminants from the raw plastic before it is melted. This ensures that the end result is both uniform with an equal distribution of elements, so that each piece is the same quality.

Screen pack filters also play a vital role in saving costs. Initially, they may seem more expensive than your regular filters, but believe them; they pay for themselves over time. Screen pack filters do their job so successfully that less raw plastic goes to waste during the manufacturing process. This means that companies are left with more money in total.

And, when the quality of the output is uniform, companies do not spend much time looking for problems. That way, they spend most of their time creating products and not fixing issues. Screen pack filters provide a cost-effective manufacturing solution, which results in cheaper and more efficient production.

The screen pack filters from Xuancheng make the whole process of production more efficient and better. This improves the extrusion process as impurities are now removed resulting in smoother and more reliable extrusion. This is especially relevant for creating complex products that require precise measurements and high models of quality.

The custom service consists of the selection of filter pore size as well as the material, shape, and other aspects and will provide customized filter products according to the diverse requirements of customers and the specific specifications of the extruder. Through customized services, the structure materials, filtration precision and other aspects of the filter can be improved in order to increase its filtration efficiency and service life. The production is based on the demands of the customer and waste is minimized to lower costs. Choose materials with the most suitable properties for the requirements and needs of the client and taking into consideration the requirements for corrosion resistance, heat resistance, wear resistance etc. Design a filter structure that is appropriate for the location and usage conditions of your customer.

The filter in the extruder is made of premium metal with very fine pores. This helps to eliminate contaminants and enhance the quality and purity of the polymer. The structure of the filter is designed to ensure a high efficiency in filtration while the material is flowing through it, thus reducing the possibility of the likelihood of clogging. This increases the efficiency of production. The metal filter is highly resistant to resistance to corrosion, wear and high temperatures. Customized filter products are available to satisfy the requirements of different clients, and also to fit with the equipment. A high-performance filtration system decreases the time lost to interruptions caused by the accumulation of impurities and boosts the productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters, which has long been committed to the production and development of extrusion filter made from plastic and has a vast amount of technical knowledge as well as industry knowledge. The products are widely used in the fields of plastic modified granulations recycling granulations, extrusions made of films and sheets and many other applications, as well as the filtration of chemical fibers. They include filters, edging mesh, spot welded mesh, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor belt, mist eliminator wire mesh, and so on. With a wide range to meet the needs of a variety of customers. It has provided services for more than 500 known plastic, petrochemical, and metallurgical production companies across the world, offering a wide markets and an impressive influence on the brand. The company has strong technical force, high degree of particularization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

A professional team of after-sales services is available to provide full technical and customer service. This can be accomplished via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to understand their use of the filters currently and their future plans. In gathering feedback from customers as well as problems encountered the after-sales team can respond quickly and give timely treatment or provide a prompt response. In the meantime it is fed back to the design department or production team to aid in the constant improvement of products and services. The experienced team investigates the cause of the problem and provides key solutions to decrease the recurrence of the same problem. Only when they are in sync, can we give customers an outstanding after-sales service experience, which in turn strengthens customer loyalty and promotes the long-term development of the company.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy