Pool filters would not be complete without the use of steel woven wire mesh. That protects the health of the water and keeps it safe for swimming. How do they do this? In the simplest of terms, they clean dirt from the water, leaves, and tiny microscopic pieces. So the bottom line is this; your pool stays crystal clear, and you swim without concern. They are constructed of horsepower filter material that is folded into a series of small pleats. It is an often polyester-based material. The fabric catches and holds any dirt or debris that is in the water, when it flows through the cartridge which allows you to have clean water.

If you have your own swimming pool, or spa — you will be only too familiar with the need to keep the water clear and sparkling. This is the role for cartridge elements. These materials are necessary because they limit dirt and other debris from entering the water supply. When the water becomes dirty, then it will be difficult to swim in that case no one will like let this happen. Maintaining clean working cartridge elements is crucial in keeping your pool or spa safe and sanitary for all who use it.

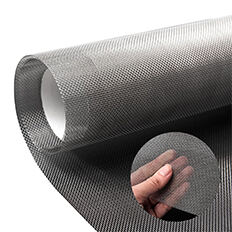

It is important in maintain the cleanliness of your pool or spa water that your stainless filter screen are performing at their best. Therefore, you have to ensure that you keep them clean periodically as over time dirt and debris can collect. You are going to have to remove the cartridge elements in order to first, clean them. Rinse them thoroughly with the hose, after you remove them from the design. Do not hesitate to soaking them first in a special cleaning solution if you notice that they are very dirty then proceed with your regular rinse. This soaking will not only clean a hard to reach grime but also make sure that the cartridge elements work perfectly fine again.

One of the important aspects to consider while choosing the cartridge element for your pool or spa is: The #1 thing to do is ensure that the cartridge element will fit with your filter system. It will not function correctly if it is either too large or too small. You want to pick a cartridge element that will also be able to filter out the appropriate dirt load. Certain cartridge elements are used to trap very small particles, while others can better contain larger debris. Selecting the right one is vital for cleaner water.

For improved performance of your pool filter, get a good quality cartridge element. These are elements which also filter better than standard so you will be drinking cleaner water. And, more expensive cartridge elements are likely to last longer than their less costly counterparts, which translates to more saved benjies in your pocket over time. Keep in mind to select a cartridge element that is compatible with your filter system for working functionality.

Xuancheng cartridge elements are the best choice for clean and clear water in your pool or spa applications! But with their high construction, they became strong at assembling dirt, dry out as good. They are also designed for durability and are built to be long lasting so you probably have to replace them less than the cheaper options. As a result, they are a wise investment for any pool owner.

It is also an easy task to clean your XDust cartridgestlements. Remove them from the filter system and wash with a hose thoroughly. You can soak them in a cleaning solution, but this should only be done for particularly dirty parts; afterward, you must wash and wear off the parts. This low maintenance keeps your pool or spa water looking sparkling clean and inviting.

Customized services consist of the selection of filter material dimensions, pore size and shape and other aspects. They can also provide custom-designed filters based on customer demands and specifications of the extruder. Customized services enable the optimization of filter parameters like structure materials, filtration precision and other parameters. This will increase the filter's filtration efficiency and lifespan. The manufacturing process is based on the requirements of the client, and waste is avoided to lower costs. Choose the materials with most suitable properties for the requirements and situations of the client in consideration of the needs for heat resistance, corrosion resistance, wear resistance and so on. Choose a filtering structure that will be suitable for the installation and usage requirements of your client.

The extruder is made of high-quality metal and features a small pores for the filter, which can effectively remove impurities from the melt of polymer as well as improve the quality and purity of the final product. The structure of the filter has been designed to ensure that the material flow remains stable in filtration as it passes through it, thus reducing the possibility of clogging and enhancing production continuity. Metal filters are invulnerable to corrosion, wear and high temperatures. According to the different needs of the customer and the specifications of the extruder specific filter solutions are available to ensure an ideal match with existing equipment and provide the most effective filtering effect. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and also increases the efficiency.

A professional team of after-sales services is available to provide full technical and customer service. This can be accomplished via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to understand their use of the filters currently and their future plans. In gathering feedback from customers as well as problems encountered the after-sales team can respond quickly and give timely treatment or provide a prompt response. In the meantime it is fed back to the design department or production team to aid in the constant improvement of products and services. The experienced team investigates the cause of the problem and provides key solutions to decrease the recurrence of the same problem. Only when they are in sync, can we give customers an outstanding after-sales service experience, which in turn strengthens customer loyalty and promotes the long-term development of the company.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the production and development of plastic extrusion filters, and has extensive technical expertise and industrial experience. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of films, sheets and other industries in addition to the filtering of chemical fiber spinning as well as other fields. The products comprise filter mesh, edging mesh, spot-welded mesh, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt wire mesh mist eliminator and more. They offer a comprehensive assortment to meet the demands of a variety of customers. The company has provided services to more than 500 famous plastic, petrochemical, and metallurgical firms around the world. Its name is well recognized and covers a wide range of markets. The company has a high technical force, high degree of specificization, complete production equipment and a complete test method. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy