لإعطائك فكرة عن كيفية متعدد الاستخدامات وهي شائعة هذه days، لفائف الشبكة الفولاذية هي فقط، اأخذ نظرة على هذا المفهوم الإبداعي للسقف الأخضر. السقوف الخضراء فريدة من نوعها لأنها توجد حيث يكون لديها المباني نمو نباتي حي على أعلى / سقف منها. إنها نظيفة وتوفّر على الأرض. يمكن أن تبرد السقوف الخضراء المباني من السقف إلى الأسفل وتساعد في تلطيف آثار الحرارة الحضرية، والمعروفة أيضًا باسم تأثير جزيرة الحرارة. السر وراء جعل السقف الأخضر نجاحًا في الزراعة هو التربة التي تحتفظ بالرطوبة ولكنها تسمح بالتصريف المناسب حتى تتمكن النباتات من الازدهار. يمكن تحقيق وظيفة هذا السقف الأخضر بواسطة لفائف الشبكة الفولاذية التي توفر دعمًا قويًا يمكن زراعة مجموعة متنوعة من النباتات عليه.

جدران الجابيون: تكيفت أسطوانات شبك الفولاذ بشكل جيد لاستخدامها في إنشاء جدران الجابيون. ما هو جدار الجابيون؟ هذا الجدار قوي للغاية ويمكن استخدامه بعدة طرق. تسهم أسطوانات شبك الفولاذ في إنشاء الهيكل القفصي الذي يحتوي على قطع الصخور. بالإضافة إلى مساعدته في التحكم في التآكل، يمكن أن يتم صنع جدار الجابيون كعنصر في مشروع حديقة أو تصميم مناظر طبيعية. إذا كنت في البناء , أنت تعلم مدى ذكاء الحصول على ألواح شبكية فولاذية. لها القدرة على جعل الخرسانة أقوى بكثير

الفولاذ لفائف الشبكة هي أيضًا رائعة لبناء أساسات المباني. إنها تخلق دعائم صلبة، مما يمكن أن يسرع من عملية البناء ويقلل من تكلفة العمالة وكذلك المواد. يجب أن يكون أساس هيكلك صلبًا كالصخرة، وإلا فإن كل ما يأتي بعد ذلك سيهتز ويتكسر.

على الرغم من أنها ليست فقط رائعة لـ البناء , يمكن أن تكون لفائف الشبكة الفولاذية إكسسوارات مفيدة عند الحديث عن تحسين المنزل. توفر الأسوار الأمان والحماية لمنزلك أو حديقتك. كما أنها رائعة للاستخدام في مشاريع تصميم المناظر الطبيعية، مثل إنشاء أسطح خضراء أو بناء جدران احتواء قوية تحافظ على التربة في مكانها وتتجنب التآكل.

القوة — تعتبر لفائف الشبكة الفولاذية من أقوى المواد التي يمكنك استخدامها في مشاريع تحسين العقار. بمجرد تركيبها بشكل صحيح، يمكن أن تدوم لسنوات عديدة دون الحاجة إلى صيانة كبيرة. وهذا التحمل يعني توفير الكثير من الأموال على المدى الطويل بسبب انخفاض عدد الاستبدالات والصيانة.

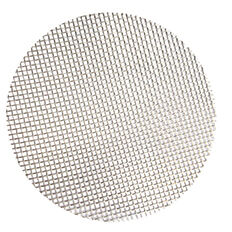

تتكون الخدمة المخصصة من اختيار حجم فتحة الفلتر بالإضافة إلى الشكل، المادة والجوانب الأخرى وستوفر فلاتر مخصصة لتلبية المتطلبات الخاصة لكل عميل والمحددات الخاصة للمضغوط. الخدمات المخصصة تمكن من تعزيز معلمات الترشيح مثل البنية، المادة، دقة الترشيح وغيرها الكثير. هذا يحسن كفاءة ترشيح الفلتر وعمره الافتراضي. يتم إجراء عملية الإنتاج وفقًا لاحتياجات العملاء، مع تجنب الهدر غير الضروري لحفظ أموال العملاء. بناءً على الاحتياجات والأوضاع التطبيقية الخاصة للعملاء، مع مراعاة المتطلبات الخاصة مثل مقاومة التآكل وكذلك مقاومة درجات الحرارة العالية، مقاومة الاحتكاك وما إلى ذلك. اختر مواد ذات خصائص مماثلة، على سبيل المثال الحديد المغلفن، الفولاذ المقاوم للصدأ وما إلى ذلك. تأكد من أن تصميم الفلتر الخاص بك يكون مناسبًا لظروف التركيب والاستخدام الخاصة بعميلك.

تتمتع الشركة بفريق محترف لخدمة ما بعد البيع، حيث يمكنها استخدام الهاتف أو خدمة العملاء عبر الإنترنت أو وسائل التواصل الاجتماعي بالإضافة إلى طرق الاتصال الأخرى لتوفير الدعم الفني والاستشارة حول المنتجات وكذلك تتبع الشحنات وإصلاح الأعطال وغيرها من الخدمات الشاملة بكفاءة للعملاء. ستقوم الشركة بالتواصل مع العملاء بشكل دوري بعد الشراء لمعرفة استخدامهم الحالي للفلاتر والخطط المستقبلية. يمكن لقسم خدمة ما بعد البيع التعامل مع شكاوى العملاء والملاحظات بشكل سريع من خلال جمع البيانات. بالإضافة إلى ذلك، يتم نقل الملاحظات أيضًا إلى أقسام تصميم وتصنيع المنتجات لتحسين جودة المنتجات والخدمات. يقوم الفريق المتخصص بتحليل سبب المشكلة ويقدم حلولًا لتقليل فرصة تكرارها. فقط عندما يعمل كلاهما معًا يمكننا تقديم تجربة استثنائية لخدمة العملاء بعد البيع، مما يعزز ولاء العملاء ويدعم النمو طويل الأمد للشركة.

شركة يانغتشو شوانشينج فلتر سكرين المحدودة، وهي الشركة المصنعة لشاشات البثق، قد خصصت نفسها لتصميم وتصنيع مرشحات البثق البلاستيكية لسنوات عديدة. لقد تراكم لديها كمية كبيرة من الخبرة الفنية والتجربة في هذا المجال. يتم استخدام المرشحات بشكل واسع في إعادة تدوير حبيبات البلاستيك المعدلة، وإنتاج الأفلام والألواح البلاستيكية وغيرها من العمليات الصناعية، بالإضافة إلى ترشيح دوامة الألياف الكيميائية وغيرها من المجالات. هناك مجموعة متنوعة من المنتجات، بما في ذلك المرشحات، الشباك الحدودية، الشباك اللحام بالنقاط، أحزمة الشبك الفولاذي المقاوم للصدأ، الشباك المدعومة، أحزمة النقل، مزيلات الضباب وغير ذلك. توفر مجموعة واسعة لتلبية احتياجات العملاء المختلفة. وقد قدمت خدماتها لأكثر من 500 شركة تصنيع معروفة في مجالات البلاستيك والبتروكيماويات والمعادن حول العالم، مما يوفر تغطية سوقية واسعة وتأثيرًا قويًا للعلامة التجارية. تمتلك الشركة قوة تقنية عالية، درجة عالية من التخصص، معدات إنتاج كاملة وعملية اختبار واسعة. كما أنها قد حصلت على شهادة نظام إدارة الجودة ISO9001:2015 لضمان جودة المنتج المستقرة والموثوقة.

يتألف مرشح الخلاط من مواد عالية الجودة ولديه حجم صغير للمسام المرشحة، مما سيزيل الفضلات من الذوبان البوليمر بفعالية ويزيد من جودة ونقاء المنتج. تم تصميم هيكل مرشح الخلاط بحيث يحافظ على كفاءة ترشيح ثابتة أثناء تدفق المادة من خلاله، مما يقلل من احتمالية الانسداد. هذا يساعد في ضمان استمرارية عملية الإنتاج. يقاوم المرشحات المعدنية التآكل والاحتكاك وكذلك درجات الحرارة العالية. وفقًا لمتطلبات العملاء المختلفة ومواصفات الخلاط الدقيقة، يمكن تصنيع منتجات مرشح مخصصة لضمان التطابق المثالي مع المعدات الموجودة ولتقديم أعلى أداء في الترشيح. يقلل الترشيح الفعال من وقت الإصلاح الناتج عن انسداد الشوائب ويعزز الكفاءة.

جميع الحقوق محفوظة © شركة يانغتشو شوانشينغ لصناعة الشاشات المرشحة المحدودة - سياسة الخصوصية