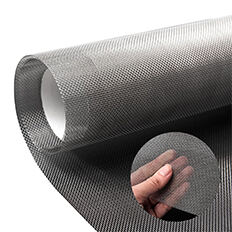

To give you an idea of how versatile and popular these steel mesh rolls are, just take a look at this creative green roofing concept. Green roofs are unique because they exist where b buildings have living plant growth on the top/ roof of them. It is clean and it saves the earth. Green roofs can cool buildings from the roof down and help to temper urban heat effects, also known as the heat island effect. The secret to making a green roof a gardening success is soil that retains moisture but allows for proper drainage so the plants can flourish. This green roof can be made to function by the steel mesh rolls that provides a sturdy support over which various plants can be grown.

Gabion Walls: Steel mesh rolls are well adapted for use in creating gabion walls. What is a gabion wall? This wall is extremely strong, and can be used in a number of ways. The steel mesh rolls contribute in setting up the cage-structure, which contains rock pieces. In addition to assisting with erosion control, the gabion wall thus can be made as a feature on a garden or landscaping project. If you are in construction, you know how smart it is to get steel mesh rolls. This has the ability to make concrete much stronger

The steel mesh rolls are also great for making foundations of buildings. They create solid supports, which can accelerate construction and reduce labor cost as well as materials. Your structure's foundation must be solid as a rock, or everything that follows it will wobble and break.

Although they are not only great for construction, steel mesh rolls can be useful accessories when it comes to home improvement. Fences are provided for safety and security of your house, or garden. They are also fantastic for use in landscaping projects, such as creating green roofs or constructing robust retaining walls which keep soil in place and avoid erosion.

Strength — Steel mesh rolls are one of the toughest materials you can use in property improvement projects. Once properly installed they can last many years without much maintenance. And this endurance means saving big bucks in the long run with fewer replacements and maintenance.

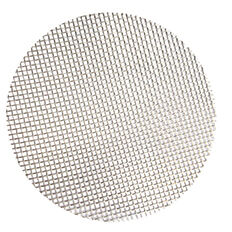

The customized service consists of choice of the size of the filter's pore along with the shape, material and other aspects and will provide customized filters that meet the specific requirements of each customer and the particular specifications of the extruder. Customized services enable the optimization of parameters for filtering like structure, material, filtration precision and many more. This improves the filter's filtration efficiency and life. The production process is conducted in accordance with the needs of the customers, while avoiding unnecessary waste in order to save customers money. According to the specific needs and application scenarios of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance as well as wear resistance, high temperature resistance, etc. Select materials with the same properties, for example galvanized iron, stainless steel and more. Make sure the filter you design is appropriate for the installation and usage conditions of your client.

The company has a professional after-sales team, utilizing the phone, customer service online or social media, as well as other contact methods, can efficiently provide customers with technical support, consultation on products along with cargo tracking, troubleshooting and other comprehensive services. The company will contact customers on a regular basis after they have purchased to learn about their current usage of filters and their future plans. The after-sales department can handle customer complaints and feedback promptly by capturing the data. Furthermore, feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The expert team analyzes the cause of the issue and offers solutions that will decrease the chance of it repeating. Only when both work together can we offer customers an exceptional after-sales customer experience, which in turn strengthens customer loyalty and promotes the long-term growth of the company.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens has been devoted to the design and manufacture of plastic extrusion filters for many years. They have built up vast amounts of technical expertise and experience in this industry. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other industrial processes, as well as the filtration of chemical fiber spinning as well as other fields. There is a variety of products, including filters, edging meshes, spot-welded meshes, stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators, and more. With a wide range to satisfy the different needs of clients. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the world, offering a wide market coverage and great brand influence. The company has a high technical force, high degree of particularization, complete production equipment and an extensive testing process. It has passed the ISO9001:2015 quality management system certification for stable and reliable product quality.

The extruder filter is composed from high-quality material and has a fine size of the filter pore, which will effectively eliminate impurities from the melt of polymer and increase the quality and purity of the product. The structure of the extruder filter is designed to maintain a constant efficiency of filtration as the material is flowing through it, reducing the chance of clogging. This helps to ensure that the production process is continuous. Metal filters resist wear and corrosion as well as high temperatures. In accordance with the diverse requirements of clients and the exact specifications of the extruder, customized filter products can be made to ensure the perfect fit with existing equipment, and to provide the highest performance in filtration. Effective filtration reduces the time it takes to repair due to blockage of contaminants and boosts the efficiency.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy