Do not ever All the rescue ? A Little Word for a Simple Thing To Keep You Clean and Safe I will tell you what is, and why this applies to so many different situations!

High strength: The stainless steel stainless steel wire mesh filter is sturdy enough, so it would not be easy to damage and the usage time will last for a long span of time. It is usually made from a stainless hard-wearing material which do not shatter or corrode easily. It is one of the durable characteristics that allow filter disc to work efficiently whenever utilized in various locations without breaking down, inside factories, kitchens or even out at your backyard without destroying and allowing poor particles to seep through. So a super hero tool that absorbs all wears and tears like an God!

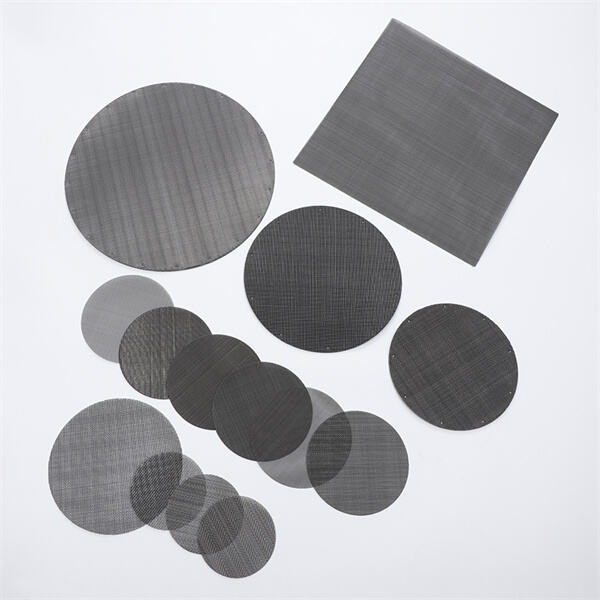

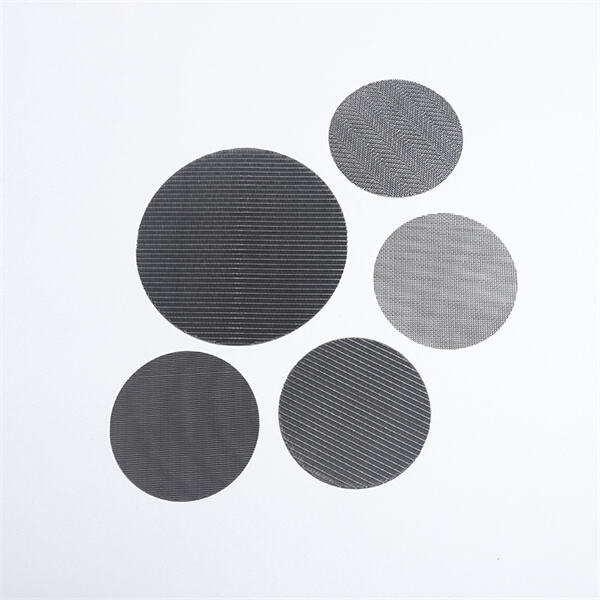

Filter coth disc / Filter Wire mesh Disc can be of any size and type of wire mesh. The filter disc is perforated and the holes in this layer may be larger or smaller, depending on what you want to get out. A Big Hole: If you wanted to filter big chunks of dirt away a bigger hole will do the job. If you were trying to filter out much smaller particles then you would select the disc with very tiny holes. Unlimited use of foil quality wire mesh from our company will be appreciated by everybody wishing to have machines on the highest standard in terms of cleaning degree of oil is not the subject which type of application mentioned, as well as garden tools clearing soil on water.

The primary role of a wire mesh filter disc is to remove dirt, debris and other impurities. In some places like factories, this can be critical (as safety is of the essence). A wire mesh filter is an excellent way of doing this, especially where cleanliness and safety are a must (such as in food processing plants). If not then you can mix the food with dust and unnecessary items which is a bad thing for everyone. So, the filter disc is a solution that will keep factory made products from spreading harmful to use and enjoy people.

An enormous benefit of a wire mesh filter disc is that you profit! That having been said, it would be the ideal solution businesses looking for low cost as they will even now provide a professional finish to their product. This standard makes it durable and useable for years without having to replace it so you save up a lot of money there as well. This allows the filter disc to remain an extra-strong surface-layer for months and months in some cases, making this filter a huge cash-cow too many companies who have volumes of material that they are filtering regularly, such as water or oil.

If you are looking for wire mesh filter disc than you may buy form the Xuancheng___. THICK STAINLESS STEEL: The filter disc is made of thick stainless steel. Solid and safe to use! Different sizes are offered as well as a mesh type suitable for your needs. Xuancheng filter disc fast cleaning, various related industries are appropriate. From a factory, a restaurant or even in your home garden, Xuancheng really does have the filter discs to satisfy your needs.

The filter of the extruder is made from high-quality steel and features small pores for filtering. This helps to eliminate impurities, and increase the purity and quality of the polymer. The filter's structure is designed to ensure constant filtration efficiency while the material flows through it, which reduces the likelihood of clogging. This helps to ensure that the production process is continuous. Metal filters have a high resistance to wear, corrosion and high temperatures. Filter products can be customized to meet the requirements of various customers and to be compatible with the equipment. Filtration efficiency that is efficient reduces the time it takes to repair due to blockage of impurities, and also increases the productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens has been devoted to the design and manufacture of plastic extrusion filters for many years. They have built up vast amounts of technical expertise and experience in this industry. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other industrial processes, as well as the filtration of chemical fiber spinning as well as other fields. There is a variety of products, including filters, edging meshes, spot-welded meshes, stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators, and more. With a wide range to satisfy the different needs of clients. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the world, offering a wide market coverage and great brand influence. The company has a high technical force, high degree of particularization, complete production equipment and an extensive testing process. It has passed the ISO9001:2015 quality management system certification for stable and reliable product quality.

The company has a knowledgeable after-sales service team, through telephone, online customer service along with social media and other ways of communication, it is able to quickly provide customers with technical support, product consulting and tracking cargo and troubleshooting, among other services. The company will contact customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the data. Furthermore, feedback is also fed back to product design and production departments to enhance the quality of products and services. The experienced team analyzes the root cause of the problem and provides basic solutions to minimize the chance of repeating the same problem. When the two are in harmony, will we be able to provide customers with an exceptional after-sales customer experience. This strengthens customer loyalty and promotes the long-term development of the enterprise.

The customized service includes the selection of filter pore size along with the shape, material as well as other elements and is able to provide custom filter products according to the different needs of customers and the specific specifications of the extruder. With the help of customized services, structure as well as the material, filtration efficiency and other aspects of the filter are able to be improved, so as to improve the efficiency of filtration and extend its the life of the filter. The process is designed according to the actual needs of the client, thus avoiding the waste that is unnecessary, and aiming to save customers money. In accordance with the specific requirements and applications of customers, taking into consideration the specific demands such as corrosion resistance and high temperature resistance wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron and more. Based on the use of the customer's surroundings and conditions for installation make sure you design a functional filtering structure, like types of plates, wound types or cylindrical type, for example.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy