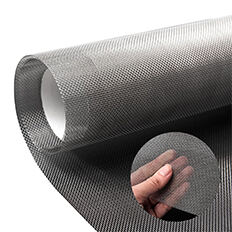

Steel mesh cloth consist of strong wires that are woven into a usable form. This is why the wires used are braided together in a very specific way which leads to a strong and durable material. One reason that fine stainless steel mesh screen cloth is so effective is because very strong, you'll see it used a lot in building projects and factories where safety issues are obviously top of the list

Safety barriers are an excellent way to use steel mesh cloth. While those kinds of barriers are a really big deal, however, because they help to keep people safe and prevent accidents from happening in places like factories or stores. The great thing about the barriers produced by company Xuancheng is very decent quality and reliability, in comparison with products of another manufacturers.

In many operation fields like construction, product transfer and maintenance, physical injury is out there as people move all over the business area so high security fences and safety barriers not only saves workers from injuries or dangerous machines but also offers a safe working zone where people can work hassle free. In addition, they are frequently put in place for use on the exterior, such as in car parks or developing sites to shield people and also vehicles from moving cars or dropping things that might cause injury

In the construction industry, stainless steel fine mesh screen is a very important cloth because of its tensile strength and suitability for usage. It makes structures such as bridges and high-rise buildings more safeable, reliable. This makes all of these structures very safe as they hold large loads and do this against winds and even with earthquakes giving safety utmost important in them with the help of the steel mesh cloth.

Steel mesh cloth is also able to be formed into really cool and unique designs that can be used for buildings. Basically, it can used to not only for protective purpose but it also adds to a design and makes the buildings look different and interesting. With the different types of steel 100 micron filter mesh cloth that is produced in Xuancheng, developers are able to make their construction very distinct so it looks special and beautiful, too.

Not only is it durable, but metal mesh screen as well as provides excellent filtration services. In the automotive industry, it is used as a middle layer in air filters for cars, which make sure that dirt and dust does not get into car engines but allow clean fresh air to come in. This enables the engine to perform better and have a longer lifespan.

The food and beverage industry utilizes steel mesh cloth for filtering liquids such as juice and beer. This filter removes the undesired chunks and pieces to help liquid flow evenly on your pallet and allow for some good aromas. All the filtering products of Xuancheng are designed to function very well such that all that is manufactured by them, comes out at the highest level and safety standards.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

A skilled team of after-sales service is available to provide full technical and customer service. This can be done via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to get their feedback on their current usage of filters and future expectations. By collecting customer feedback and issues that arise in the service after sales department, it can respond rapidly and give timely treatment or respond. At the same time the feedback is passed back to the design department or production department to promote the constant improvement of products and services. The expert team analyzes the root of the problem and provides solutions to make it less likely to occur repeating. When the two are in harmony, can we provide customers with an exceptional after-sales customer experience. This improves customer satisfaction and helps the growth of the enterprise.

The extruder filter is constructed of high-quality metal and has a fine filter pore size, which effectively removes any impurities that are present in the polymer melt as well as improve the quality and purity of the final product. The filter's structure is designed to ensure a continuous filtration rate while the material flows through it, which reduces the chance of clogging. This increases the efficiency of production. Metal filters are impervious to wear, corrosion and high temperatures. In accordance with the diverse requirements of customers and the specific specifications of the extruder, specific filter solutions can be provided to ensure an ideal match with existing equipment, and to provide the highest performance in filtration. A high-performance filtration system decreases the amount of interruptions caused by the accumulation of impurities and increases productivity.

Customized services include the selection of the filter material, pore size and shape, as well as other aspects. They can also provide customized filters according to customer requirements and specifications for the extruder. The customized services allow the optimization of parameters for filtering such as structure material, filtration accuracy and more. This can improve the efficiency of filter filtration and longevity. The production is performed according to the specific requirements of the customer, and avoids excessive waste, in order to save customers money. According to the specific needs and applications of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Choose the materials that have corresponding properties, such as galvanized iron, stainless steel, etc. Create a filter design that is appropriate for the installation and operating conditions of your client.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy