Stainless wire mesh is widely used in industrial industry. Whether used for sifting materials, or guarding machines, this promotional gift helps keep production line processes efficient and quality assured. Xuancheng knows how important it is to find the perfect stainless steel wire mesh screen for your application while also understanding some of the newer methods and trends that help take surface preparation and finishing to new levels. Here we delve into ways in which stainless wire mesh screens can enhance your operations, along with the flexibility to be effective in various applications, how to choose the correct one for your needs and keep up-to-date on new technology advances as well as answers some of our customers’ more frequently asked questions about these important tools.

For example, stainless wire mesh screens are an excellent product in the production process because they provide superior filtration that allows only particles of a desired size to pass through them and do not allow any impurities through. Adding these screens on your production line will allow you to keep product quality at par with demand, minimize waste and increase efficiency. In the medical field such as pharmaceuticals, twilled weave stainless wire mesh screen is used for filtering out impurities in drugs, resulting secure and pure medicines. In the food and beverage industry, these screens are used to sift through soil particles from liquids preventing unwanted dirt particles in liquid materials. The application of woven wire mesh screens on various banners enhances product quality and productivity in manufacturing plants.

Stainless steel wire mesh screens are a favorite of many with the industry being so prevalent. Automotive to aerospace, construction to petrochemicals - these screens are an integral part in the operational systems. For example, in the automotive industry, screens made of stainless steel wire are employed to filter impurities from engine components used in liquids, which could compromise the function and durability of these parts. Not only that, the ss wire mesh screen play a key role in sieving various substances in the oil industry for refining them and to produce cleaner energy sources. Stainless wire mesh screens versatility depends on another factor that is their capability to meet different manufacturing requirements, and therefore they are absolutely indispensable in a wide range of applications.

Choosing the Right Stainless Wire Mesh Screen for Your Manufacturing Needs – It’s Important You have more than a few options regarding the type of stainless wire mesh screen that you use and there are certain criteria to consider when making this purchasing decision. Mesh handling, materials used in construction and weaving method are all needed to be carefully inspected to fit in your applications! Xuancheng has a multitude of stainless wire mesh screens available to suit your needs, which can cover most specifications such as levels of filtration, durability and temperature resistance. With your operations in mind, we work directly with you and our staff to find the best stainless wire mesh screen to fit your business’ needs during each step of production for an efficient solution to maximize output.

With technological design innovations, developments and now the most comprehensive range of stainless steel filtration screen solutions. Technological advances such as nano coatings to add longevity, composite materials for added strength and precision weaving techniques for fine filtration have enabled these screens to push the limits of what they can do. Xuancheng is at the cutting-edge of these new developments and has invested heavily in research and development to bring our customers innovative products. Keeping current with the cutting edge developments of wire mesh screen stainless steel production technology enables manufacturers to benefit from these improvements and be competitive in today’s market.

Mesh size of stainless wire mesh screen is defined by the number of openings per linear inch. The mesh size is the number of wires per square inch, and the lower the number of mesh, the larger particles can be filtered by that particular screen. Evaluate your particular filtration requirements and discuss mesh specifications with our knowledgeable staff to determine the optimal selection for you.

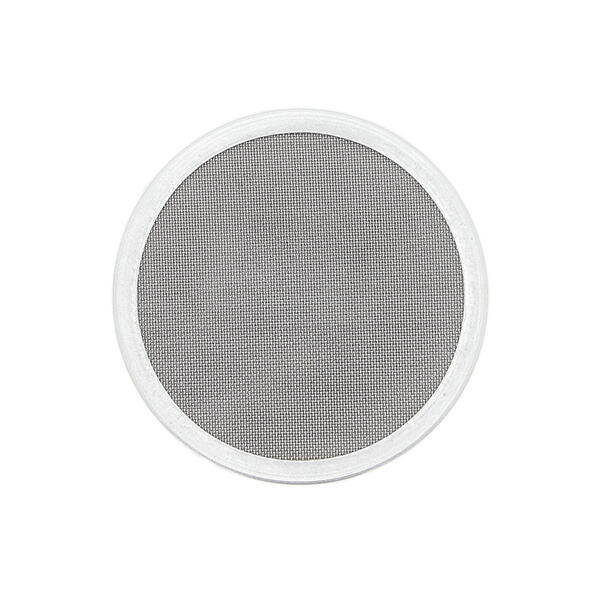

The extruder filter is composed from high-quality material and has a fine size of the filter pore, which will effectively eliminate impurities from the melt of polymer and increase the quality and purity of the product. The structure of the extruder filter is designed to maintain a constant efficiency of filtration as the material is flowing through it, reducing the chance of clogging. This helps to ensure that the production process is continuous. Metal filters resist wear and corrosion as well as high temperatures. In accordance with the diverse requirements of clients and the exact specifications of the extruder, customized filter products can be made to ensure the perfect fit with existing equipment, and to provide the highest performance in filtration. Effective filtration reduces the time it takes to repair due to blockage of contaminants and boosts the efficiency.

The company has a professional after-sales service team, through the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical assistance, product advice as well as cargo tracking as well as troubleshooting services. The company will contact customers regularly after the sale to find out their usage of filters and to anticipate their needs for the future. After-sales personnel is able to respond to customer issues and comments quickly by gathering the data. Additionally, feedback from customers can be passed on to the product design and production departments in order to improve the quality of products and services. The expert team determines the source of the issue, and then provides fundamental solutions to reduce the likelihood of repeating the same problem. The two are in sync and only then can we provide our customers with the highest quality customer service. This in turn can increase customer satisfaction and allow the business to increase its growth.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens has been devoted to the design and manufacture of plastic extrusion filters for many years. They have built up vast amounts of technical expertise and experience in this industry. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other industrial processes, as well as the filtration of chemical fiber spinning as well as other fields. There is a variety of products, including filters, edging meshes, spot-welded meshes, stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators, and more. With a wide range to satisfy the different needs of clients. It has provided services for over 500 well-known plastic, petrochemical and metallurgical manufacturing companies around the world, offering a wide market coverage and great brand influence. The company has a high technical force, high degree of particularization, complete production equipment and an extensive testing process. It has passed the ISO9001:2015 quality management system certification for stable and reliable product quality.

Customized services can include the choice of the filter material along with the pore size and shape and other elements. They also can provide custom-designed filters based on customer requirements and specifications for the extruder. Customized services allow for the optimization of parameters for filtering like structure and material, filtration precision and many more. This can improve the filter's filtration efficiency and life. The production is performed according to the actual needs of the customers, while avoiding unnecessary waste in order to help customers reduce costs. According to the specific needs and scenarios for customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have similar properties, like stainless steel, galvanized iron or galvanized iron. Create a filter design that is appropriate for the installation and operating conditions of your customer.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy