Hey everyone. Who here has ever even seen a stainless-steel wire mesh screen? Now, I know that seems crazy but when you break it down it's really not that much. Stainless Steel Wire Mesh- This mesh is made from SS wires and it is the most robust material. It preserves things from harsh outside such as wind, rainfall and also parasites. While we have already gone through what Camellia Oil is and how it comes to be processed, there are too many magical properties of this oil that NEEDS some limelight so let us give you a deeper dive into the benefits. Strength Probably one of the major pros of using a stainless-steel wire mesh screen would be its strength. it has very strong as it’s made up of the stainless steel, it does not get weak by applying an extra force & pressure on it. That makes it perfect for environments where heavy machines or tools will be used, like factories and construction sites. But it also good for those places which face strong wind or heavy rain. That is critical for safeguarding our homes and workplaces, because the screen enables insulating buildings from harm.

One of the none other than notable benefits primarily due to which these stainless-steel wire mesh screens should be used more and also above all is tolerance. This means you can have it for a considerably longer time, and they will not rust or depreciate quickly. So that straight away typically the best solution for property owners who also are afraid bugs while different such things as. Changing out your screens or repairing them every time they get too weathered can be expensive, but with this, you will not have to do that. We already pointed out above that such displays are way too awesome to be fitted into factories or industrial premises. This makes them ideal for with standing heavy weight and not shattering compared to the press board under heavy machinery. They are so they can give you many years of use without having to be replaced. These are the reasons they are good for your Factories or Warehouses where you get to work on mostly heavy machines. After all, they make the work environment a safer place and nothing will happen.

And a stainless-steel wire mesh screen is more practical and can even look beautiful. It is architecturally relevant and can be created in a SLAM style. And when those screens don't just do a job but also contribute to the charm of your residence. It permits a substantial amount of natural light to stream in and keeps the insides energetic and animated. Perfect for both domestic and professional or public use.

Stainless steel wire mesh screen So useful for home lives They can help to keep windows and doors while there are bugs outside (which later in the year is most definitely necessary). The very last thing any of us want is for flies and mosquitoes to have you scratching yourself all day long at home. Outdoor mesh screens: protect patios or decks from bugs and give friends, family gatherings a more comfortable place. Great place to live without the pests.

These screens even provide a better way of ensuring safety from possible hazards for your home and family, the most they offer. Rodent-proof stainless steel wire mesh screens can be installed in windows and doors to prevent burglaries from entering the room. One more layer of safety makes you feel safer at home. It will also aid in preventing little kids and pets from falling off the door without there being watched over, hence keeping them safe. For families that is peace of mind worth any amount of money to know their loved one are well cared for.

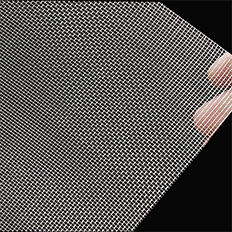

The filter in the extruder is constructed of top-quality metal, and it has tiny pores for filtering. This permits it to eliminate impurities and improve the purity and quality of the polymer. The structure of the filter is designed to ensure that the material flow remains stable in filtration throughout its passage, reducing clogging and improving production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. Filter products that are custom-designed can be found to meet the requirements of different customers, and to match the equipment. A high-performance filtration system reduces the amount of delays caused by clogging of impurities and boosts the productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd., one of the producers of extruder screening has been devoted to the development and production of plastic extrusion filters for a number of years. They have amassed the most extensive technical knowledge and have gained experience in this business. They are extensively used in the industries of plastic granulations modified by granulations recycling granulations, extrusions made of sheets and films, and many others along with the filtration of chemical fibers. There is a broad range of products that include filters, edging meshes, spot-welded meshes stainless steel mesh belts reinforced wire mesh, conveyor belts, mist eliminators and so on. offering a variety to meet the varied needs of the customers. It has provided services to more than 500 prominent plastic, petrochemical and metallurgical manufacturing companies around the globe, with a vast market coverage and great branding influence. The company has a high technical power, a high degree of specialization, complete production equipment and a complete test method. The company has been certified ISO9001:2015 to ensure stability and reliability product.

Customized services include the selection of the filter material, pore size and shape, as well as other aspects. They can also provide customized filters according to customer requirements and specifications for the extruder. The customized services allow the optimization of parameters for filtering such as structure material, filtration accuracy and more. This can improve the efficiency of filter filtration and longevity. The production is performed according to the specific requirements of the customer, and avoids excessive waste, in order to save customers money. According to the specific needs and applications of customers, taking into consideration the specific demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Choose the materials that have corresponding properties, such as galvanized iron, stainless steel, etc. Create a filter design that is appropriate for the installation and operating conditions of your client.

The company has a professional after-sales team, utilizing the phone, customer service online or social media, as well as other contact methods, can efficiently provide customers with technical support, consultation on products along with cargo tracking, troubleshooting and other comprehensive services. The company will contact customers on a regular basis after they have purchased to learn about their current usage of filters and their future plans. The after-sales department can handle customer complaints and feedback promptly by capturing the data. Furthermore, feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The expert team analyzes the cause of the issue and offers solutions that will decrease the chance of it repeating. Only when both work together can we offer customers an exceptional after-sales customer experience, which in turn strengthens customer loyalty and promotes the long-term growth of the company.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy