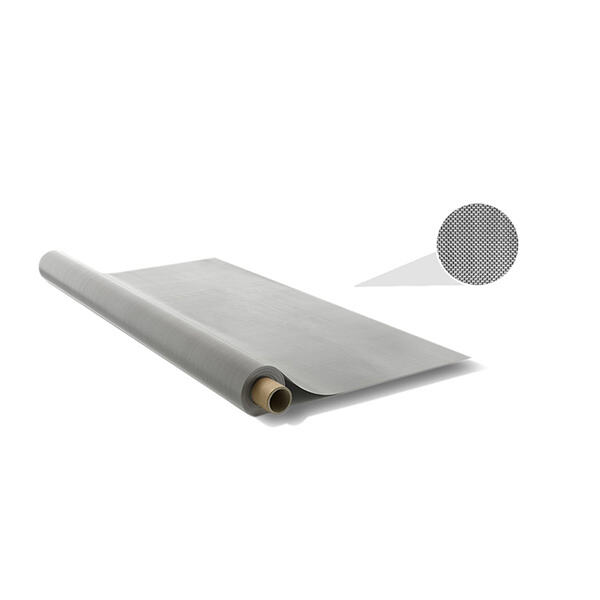

Ever seen little holes in a window or screen door? Probably, Yes and by now you must have guessed stainless steel mesh rolls! These rolls consist of high tensile strength metal wires woven into fabric with a mesh pattern, like a net. This article will discuss the applications of Xuancheng stainless steel mesh rolls in various industries. We will also be talking about why these rolls are so robust, making them ideal for all kinds of uses.

Xuancheng stainless steel mesh roll metal wires are a tempered one. These steels have very high tensile strength and are resistant to rust. This indicates that because these mesh rolls are so effect to not easily fall apart when pressure is applied, they will continue to perform function in areas of high moisture or humidity. On the other hand, you can use it for a lot of things, including marine applications like on boats and piers since these rolls are made to withstand saltwater or food factory usage where you have plenty of liquids and chemicals. The Leaf Disc Filter also offer some resistance to rust, which means they can keep going for a long time even under harsh conditions.

What really sets Xuancheng stainless steel mesh rolls apart is the fact that they are so versatile. This is applicable in various lines of work and sectors. For example, in the food industry mesh rolls can be used as a filter to mechanically remove any unwanted particles such as dirt from the food material making it clean and safe for consumption. They are used as screeners which sift rocks to separate precious materials in the mining industry, and also have other uses like bakery machines. Furthermore, these mesh rolls can also be true life-savers in construction sites where debris might fall, acting as a barrier between working personnel and objects that are going to hit the ground.

Other than that, Xuancheng stainless steel mesh rolls for the strength is not only durable costs to install and maintain. The rolls are cut according to the requirement for different sizes and shapes of sheets, catering to projects that vary in size and bit. Moreover, this adaptability is its utility for multiple applications. Since the Filter Element are constructed from stainless steel, you will not experience rusting such as you perhaps would certainly with various other products so there be fewer times changing them. Due to their durability, you end up saving money in the long run by avoiding replacements and repairs, making them an intelligent investment.

The stainless steel mesh roll has other outstanding characteristics that include the variety of sizes and shapes available for sale. This means you can use them on any project you might be working on. These rolls can be used to make fences, or you could use them to cover holes in buildings and homes to prevent pest infestation. Alternatively, they could be used as filters in water treatment plants or in devices for sorting out various materials. Mesh rolls that can be customized make it such that you can have them fit and fulfil your needs and works just as right.

For filtering and screening, Stainless steel mesh rolls are a very good option. They are some of the longest lasting containers because they take less care and maintenance. So in the long run, it's a cost saver since you save even more because of its durability that won't have to spend on replacements or repairs too often. In general, these mesh rolls are quite strong and can withstand higher pressures than many other types of materials. For this reason the Sintered Filter Mesh are extremely useful in environments, which would make other materials deficient.

Customized services can include the choice of the filter material along with the pore size and shape and other elements. They also can provide custom-designed filters based on customer requirements and specifications for the extruder. Customized services allow for the optimization of parameters for filtering like structure and material, filtration precision and many more. This can improve the filter's filtration efficiency and life. The production is performed according to the actual needs of the customers, while avoiding unnecessary waste in order to help customers reduce costs. According to the specific needs and scenarios for customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have similar properties, like stainless steel, galvanized iron or galvanized iron. Create a filter design that is appropriate for the installation and operating conditions of your customer.

Yangzhou Xuancheng Filter Screen Co., Ltd. is a reputable manufacturer of extruder filter, which has been dedicated for many years to the creation and development of extrusion-based plastic filters and has profound technical accumulation as well as industry knowledge. The filters are used extensively in plastic modified granulation recycling granulation, extrusion of films, sheets and other products, as well as the filtering of chemical fiber spinning and other industries. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt, wire mesh mist eliminator, etc. With a wide assortment to meet the demands of various clients. The company has offered services to more than 500 famous plastic, petrochemical and metallurgical production companies across the globe, and has a broad market coverage and strong impact on brand image. The company has a strong technological force, high degree of specialization, complete production equipment and an extensive testing process. The company has been accredited with ISO9001:2015 to ensure the stability and reliability of its product.

The company has a professional after-sales team, utilizing the phone, customer service online or social media, as well as other contact methods, can efficiently provide customers with technical support, consultation on products along with cargo tracking, troubleshooting and other comprehensive services. The company will contact customers on a regular basis after they have purchased to learn about their current usage of filters and their future plans. The after-sales department can handle customer complaints and feedback promptly by capturing the data. Furthermore, feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The expert team analyzes the cause of the issue and offers solutions that will decrease the chance of it repeating. Only when both work together can we offer customers an exceptional after-sales customer experience, which in turn strengthens customer loyalty and promotes the long-term growth of the company.

The extruder is made of high-quality metal and features a small pores for the filter, which can effectively remove impurities from the melt of polymer as well as improve the quality and purity of the final product. The structure of the filter has been designed to ensure that the material flow remains stable in filtration as it passes through it, thus reducing the possibility of clogging and enhancing production continuity. Metal filters are invulnerable to corrosion, wear and high temperatures. According to the different needs of the customer and the specifications of the extruder specific filter solutions are available to ensure an ideal match with existing equipment and provide the most effective filtering effect. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and also increases the efficiency.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy