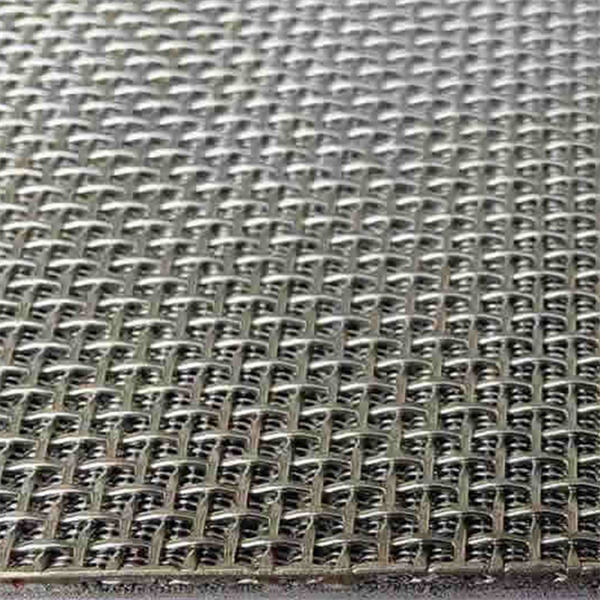

Do you know the 5 layer sintered wire mesh? It may seem hard, but is a really cool technology that helps variety of industries. Sintered wire mesh is constructed from multiple layers of wire mesh that are bonded together through a specialized heat and pressure process. Then it is processed into a solid, durable, and versatile material.

Filtration is the physical separation of solids from liquids or gases. It is widely used in many common settings, such as cleaning water or filtering air. The sintered wire mesh is transforming the filtration process into a new era with its high-efficiency performance, which was impossible to achieve with the traditional filtration equipment. Unlike conventional filters, sintered wire mesh has small openings of uniform size, making it effective in capturing even the most minor portions of dirt and debris. That means it works so well that it's perfect for vital jobs — purifying water, separating oil and gas, and even handling food.

Xuancheng is a manufacturer of sintered wire mesh products. They will show you how this special material will serve very user friendly which is helpful for your business. The following are some of the positives of using sintered wire mesh:

Chemical Resistant – Sintered wire mesh also is designed to withstand strong chemicals and acids. It enables you to use it in various cases without being spoiled or worn out. This feature is very useful so in chemical processing as well as related industries dealing with a lot of harsh substances.

Easy to Clean – Arguably one of the best characteristics of sintered wire mesh is that it is easy to clean and reuse. That means you don’t have to change it very often, so it helps save some money and resources in the long run.

Customizable – One more exciting aspect of sintered wire mesh is that it can be tailored according to specific requirements. Depending on your needs, you can alter the number of layers and the force of the holes to filter out. This kind of customizability means that it is widely applicable across various sectors.

Sintered wire mesh is manufactured by a special process where layers of wire mesh are subjected to heat and pressure. It sets forth a dense and sturdy material in the filtering process. The amount of layers and size of the holes can be adjusted to achieve the finest filtering available for your application. Stainless steel, bronze, and titanium are examples of materials that can be used to make sintered wire mesh. And each of these materials has different strengths and properties that determine how well they can resist heat and chemicals.

The company has a professional after-sales team, utilizing the telephone, online customer support along with social media and other contact methods, can efficiently provide customers with technical support, product consultation as well as cargo tracking and troubleshooting, among other services. The company will contact customers regularly after the sale to find out their current usage of filters and to anticipate their needs for the future. By collecting customer feedback and problems encountered in the service after sales department, it is able to respond quickly and offer a prompt respond. Furthermore, feedback is also passed back to product design and production departments to enhance products and services. The team of experts thoroughly investigates the cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. Both complement each other and only then can we offer our customers a high-quality customer service. This improves customer loyalty and assist the company to expand.

Yangzhou Xuancheng Filter Screen Co., Ltd. is an experienced manufacturer of extruder filters that has been devoted for a long time to the production and development of plastic extrusion filters, and has extensive technical expertise and industrial experience. The filters are used extensively in plastic modified granulation, recycling granulation, extrusion of films, sheets and other industries in addition to the filtering of chemical fiber spinning as well as other fields. The products comprise filter mesh, edging mesh, spot-welded mesh, automatic switching stainless steel mesh belt reinforcing mesh, conveyor mesh belt wire mesh mist eliminator and more. They offer a comprehensive assortment to meet the demands of a variety of customers. The company has provided services to more than 500 famous plastic, petrochemical, and metallurgical firms around the world. Its name is well recognized and covers a wide range of markets. The company has a high technical force, high degree of specificization, complete production equipment and a complete test method. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

The filter in the extruder is constructed of top-quality metal, and it has tiny pores for filtering. This permits it to eliminate impurities and improve the purity and quality of the polymer. The structure of the filter is designed to ensure that the material flow remains stable in filtration throughout its passage, reducing clogging and improving production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. Filter products that are custom-designed can be found to meet the requirements of different customers, and to match the equipment. A high-performance filtration system reduces the amount of delays caused by clogging of impurities and boosts the productivity.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy