Do you ever wonder how things end up at being a clean solution? Filters on the other hand, are entrance criteria that help to manage this flood of ideas down so you can keep your filing cabinet clean and organized. The is one such excellent kind. These are ideal for the filtration of liquids, gases and (technically) solids!!! These are stainless steel filter mesh 5 microns made by a company called Xuancheng, and they can come in quite handy for a variety of different uses and applications. We will explore stainless steel filter discs in this blog post, focusing on the many ways they could be helpful and essential for cleansing processes.

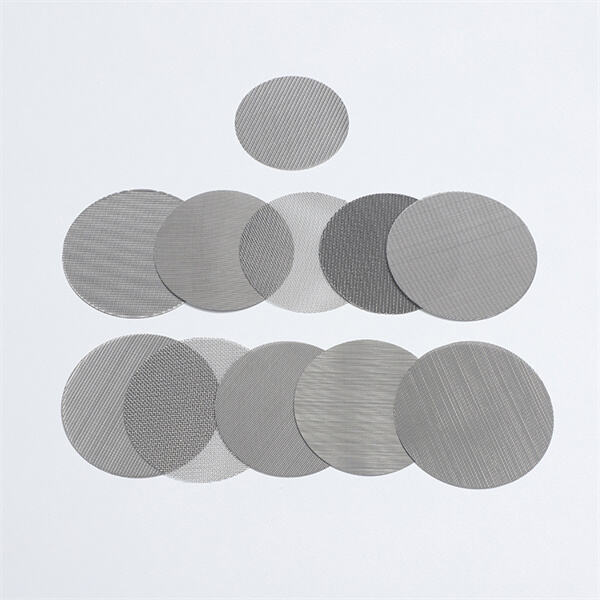

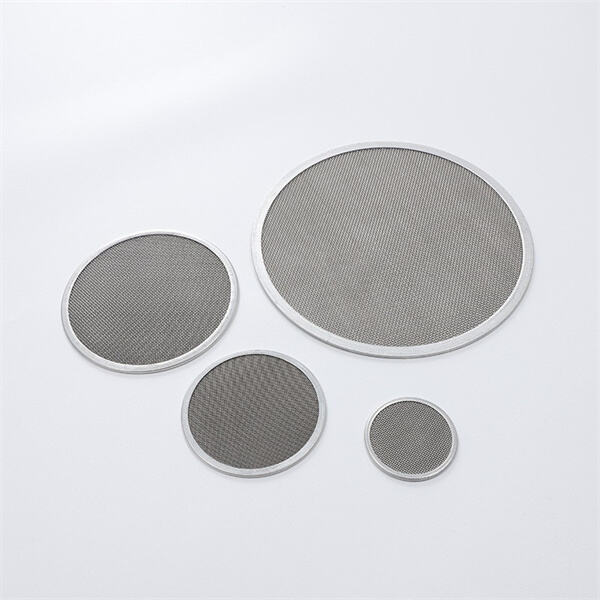

Stainless steel filter discs are constructed from a highly robust material stainless steel. That makes them long lasting and resistant to rust, which is an essential when it comes to filters. They are flat disks with numerous small holes…almost like a household strainer. The shape and size of these discs can vary based on the type of work they are designed to perform. The versatile nature of their function allows them to filter a wide range of materials be they liquids, gases, or other types of solid substances.

Stainless steel filter discs are popular in filtering for the reason that they can only retain those impurities as bacteria, oil and dust or other micro granules. Tiny perforations in the disks (3) capture excess particles — but not great samples. And this is what makes the filtering process work so effectively, producing great products. With the help of these filter discs industry can make sure that they are removing hazard materials and by-products but retaining life supporting substances.

Stainless steel filter discs have the major benefit of costing less over time due to their long lifespan. While other filters may have to be replaced more frequently, the stainless steel discs of this choice do not need to be modified as often. This equates to lower waste and ultimately costs fewer in the long term. They are also easy to wash and you can re-use them after cleaning. Reusability of the discs are very helpful as they give you an effective and low-cost way to spread information.

Stainless steel filter discs are ideal for applications in which high temperatures are requires due to their ability to cope with the extreme conditions. Everywhere there are hot liquids or gases that require filtering, either with problems in handling a filter material. In the production process, other types of filters can break down in this heat. However, stainless steel filter discs are composed of high temperature resistant strength, which means these types of filters can function without any difficulties or visual impairments even at very difficult operating conditions.

Now, let's see how easy it is to use as well as maintain stainless steel filter discs. All you do is put them in your filtration system, and watch them go to work. Once you finish filtering and use, can easily pull out and wash them. You can rinse them with water or it a special cleaning solution to make the spotless. So it is highly advisable to wash them often to work like always perfect and efficient whenever you use them.

A skilled team of after-sales service is available to provide full technical and customer service. This can be done via the company's customer service, online customer service and social media. The company will communicate with customers frequently after a sale to get their feedback on their current usage of filters and future expectations. By collecting customer feedback and issues that arise in the service after sales department, it can respond rapidly and give timely treatment or respond. At the same time the feedback is passed back to the design department or production department to promote the constant improvement of products and services. The expert team analyzes the root of the problem and provides solutions to make it less likely to occur repeating. When the two are in harmony, can we provide customers with an exceptional after-sales customer experience. This improves customer satisfaction and helps the growth of the enterprise.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

Yangzhou Xuancheng Filter Screen Co., Ltd., the manufacturer of extruder screens is devoted to the creation and manufacturing of plastic extrusion filters for several years. They have built up vast amounts of technical expertise and expertise in this field. The products are widely used in plastic modified granulation, recycling extrusion of films, sheets and other industries and also for the filtering of chemical fiber spinning as well as other fields. There are many kinds of products that include filters, edging meshes, spot-welded meshes, stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators, etc. and a range of products that can meet the various requirements of clients. The company has served over 500 well-known plastic, petrochemical and metallurgical enterprises in the world. Its name is well popular and has a broad range of markets. The company has a strong technical force and has the most advanced production equipment, as as complete testing methods. It has been awarded the ISO9001:2015 quality management system certification for stable and reliable product quality.

The extruder filter is made of high-quality metal and features a very fine size of the filter pore, which effectively removes impurities from the polymer melt and enhance the purity and quality of the polymer. The filter's structure is designed to maintain a high efficiency in filtration while the material moves through it, reducing the possibility of clogging. This improves production continuity. The filter made of metal has a superior resistance to corrosion, wear as well as high temperatures. As per the specific requirements of clients and the exact specifications of the extruder specific filter solutions are available to ensure a perfect match with existing equipment and provide the most effective filtration effect. Filtration efficiency that is efficient reduces the amount of time that is lost due to the clogging of impure materials and improves productivity.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy