The air can cleaning in liquid or gas contain must use the one of the main part as an electrostatic filter element. This is made of tiny pieces of substances that are packed and shaped into a filter with small holes. The sheath should be of common/heat insulation quality like clay, metal or even plastic. This is also why the steel woven wire meshs are a more common and more official one that is used for filters in factories as these will tend to function better than anything else could help ensure that they last longer than anything other regular filter.

Sintered filter elements are full of characteristics that have made them popular in numerous plants This allows factories to produce parts faster and with less resources, AND they clean better! We always feel great helping our clients at Xuancheng with some fresh production methods and ways to solve their problems. Here are a few of the excellent benefits that you will be accessing through our Xuancheng sintered filter elements:

Specialty solutions: Some of the jobs may call for special cleaning. And as your request we also can do the size producing and processing in Xuancheng stainless filter screens. This therefore allows us to design filters that are very specific and thus they become ideal for challenging cleaning operations which do not get clean with standard filter.

Factory now need to think wise and buy sintered filter elements which are the best for them in the long run. With the fantastic technology and customer-centric feature-set live at Xuancheng, customers can now be assured that they have access to world-class iGaming products which will grow their businesses. The above reasons mentioned are massive, but there are more than enough to invest the filter elements.

Sintered filter elements from Xuancheng allow factories to become increasingly efficient by getting more done and eliminating many of the stopped or idle time that normally occurs. We know every plant is unique, and we can customize to any detail that you would like. Applications where our sintered filter elements improve performance

Easy Cleanup: Compared to common filters, the sintered filter is easier to clean by just rinsing off because of its stainless steel material. That makes it simply a cost-effective and efficient cleaning method in the long term. In short, it reduces the time and duration of maintenance required to get factories up again.

Compatible with all materials: spiral filter elements are efficient and are suitable to be used on different chemicals, and more. One of the reasons air hoists have such a broad application base is their versatility in design which allows these important components to handle many different kinds of industrial applications ranging in size and operation.

Yangzhou Xuancheng Filter Screen Co., Ltd., a manufacturer of extruder screens, has been dedicated to the design and manufacture of plastic extrusion filter for a long time. They have built up an extensive amount of technical know-how and have gained experience in this business. They are extensively used in the manufacture of granulations that are modified with plastic, recycling granulations, extrusions made of films and sheets and many more along with filters for spinning chemical fibers. There is a variety of products available, such as filters, edging meshes, spot-welded meshes stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators etc. with a full range that can meet the various requirements of our customers. The company has supplied more than 500 of the most prestigious plastic, petrochemical, and metallurgical firms around the world. The company's name is widely acknowledged and is able to cover a variety of markets. The company has strong technical force, an extremely high degree of particularization, complete production equipment and an extensive testing process. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

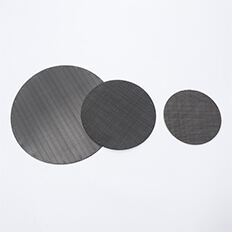

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

The customized service includes the choice of the size of the filter's pore along with the shape, material and other factors as well as the ability to create custom filter products based on the diverse requirements of customers as well as the specific requirements of the extruder. Customized services enable the optimization of parameters for filtering like structure materials, filtration precision, and others. This can improve the filter's filtration efficiency and longevity. The manufacturing process is based on the requirements of the client and waste is minimized to save money. Based on the particular requirements and applications of customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have corresponding properties, such as stainless steel, galvanized iron or galvanized iron. Make sure the filter you design is appropriate for the installation and usage requirements of your customer.

The company has a knowledgeable after-sales team, utilizing phone, online customer service, social media and other methods of contact, they can offer customers quick technical assistance, product advice as well as cargo tracking as well as troubleshooting services. After the items are purchased, regular communication with the buyer is carried out to understand the usage of their filters as well as the future requirements and expectations. By collecting customer feedback and issues encountered in the service after sales department, it is able to respond promptly and provide prompt treatment or respond. Additionally the information is relayed back to the design or production team to aid in the constant improvement of products and services. The expert team analyzes the root cause of the issue, and then provides essential solutions to prevent the chance of repeating the same problem. When the two are in harmony, can we provide customers with an excellent after-sales service experience, which in turn enhances customer loyalty and aids in the development of the enterprise.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy