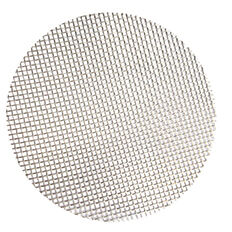

A 80-mesh filter is a mesh which catches any small 80-mesh or smaller particles. What this means is that it can filter things that are tough to see, even with the human eye. Why is this important? When it comes to many other jobs and industries, even the smallest particles in the final product can cause huge problems. These particles in turn can influence the integrity and quality of the products being manufactured.

Companies that Go With an 80 Mesh Filter can Choose Better the Quality of their Final Products Such as in the food industry, small particles may result with foods that are unsafe to consume and can also affect its flavor. And if this unclean food is consumed by people, they will get sick as no one wish their loved ones to get in trouble due to bad stomach or loose motion. Everyone wants their food to be safe and delicious so they remain satisfied and healthy.

Smaller particles can cause machines to fail in factories and disable them. This can result in costly repairs and may cost companies a considerable quantity of cash. A lot of this can be eliminated by using an 80 mesh filter throughout the production process, which will help companies save money as well as extend the life of their machines.

Cleaning Will Keep Your 80 Mesh Filter Working Properly After sometime the filter may get accumulated with dirt and particles, which will slow down its work at filtering out unwanted chemicals. As you have seen, all these compete or reduce the efficacy of your device, so to avoid any of this happening, you need to filter and look after it.

The best area to utilize 80 mesh filters is for the manufacture of drugs. In this industry a little particles can be incredibly hazardous and even lead to death. Medicine manufacturers can confirm that their products are safe to use, for people, through using an 80 mesh filter. This is crucial as patients depend on these drugs for their improvement.

The application of 80 mesh filters are widely used in the work and life, especially in the food processing industry, pharmaceutical industry and water treatment. These filters are also used in other products such as fuel filters, air filters and HVAC (heating, ventilation, and air conditioning) filters that make our environment safer and healthier.

The companies would be unable to produce a safe and effective product for their customers if there were no filters in the 80 mesh range at their disposal. The filters (upstream and downstream) are an important part of the manufacturing production process, that is why there are many enterprises like Xuancheng (other brands with similar products with different designs) committed to providing customers best-in-class filters.

The extruder is made of high-quality metal and features a small pores for the filter, which can effectively remove impurities from the melt of polymer as well as improve the quality and purity of the final product. The structure of the filter has been designed to ensure that the material flow remains stable in filtration as it passes through it, thus reducing the possibility of clogging and enhancing production continuity. Metal filters are invulnerable to corrosion, wear and high temperatures. According to the different needs of the customer and the specifications of the extruder specific filter solutions are available to ensure an ideal match with existing equipment and provide the most effective filtering effect. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and also increases the efficiency.

The customized service includes the choice of filter pore size materials, shapes, and other factors as well as the ability to create custom filters that meet the specific requirements of each customer and the specifications of the extruder. By utilizing customized services, the structure and material, the filtration accuracy and other aspects of the filter can be optimized so as to enhance its filtration efficiency and service life. The process is designed according to the specific requirements of the customers, while avoiding unnecessary waste in order to save customers money. Based on the particular requirements and requirements of the customers, considering the special demands such as corrosion resistance as well as high temperature resistance wear resistance, etc. Select materials with the same properties, for example stainless steel, galvanized iron and more. Create a filter design that is appropriate for the installation and usage conditions of your client.

Yangzhou Xuancheng Filter Screen Co., Ltd., an extruder screen manufacturer is devoted to the design and manufacture of plastic extrusion filter for a long time. They have amassed vast amounts of technical expertise and know-how in the field. They are extensively used in the fields of plastic modified granulations recycling granulations, extrusions made of films and sheets and many more in addition to filters for spinning chemical fibers. They comprise filters, edging mesh, spot-welded meshes, automatic switching stainless steel mesh belt, reinforcement mesh, conveyor belt, wire mesh mist eliminator, and so on. They offer a comprehensive collection to meet the needs of a variety of customers. The company has served over 500 well-known plastic, petrochemical and metallurgical companies around the world. The brand is well known and it is able to cover a variety of markets. The company has strong technical strength and possesses specialized production equipment, as well with a comprehensive testing process. The company has been accredited to ISO9001:2015 to ensure a stable and reliable product.

The company is equipped with a skilled after-sales service department, which is accessible via phone, online customer service or social media, as well as other communication methods, can quickly provide customers with technical support, consultation on products as well as cargo tracking along with troubleshooting services. After the goods are sold, regular and in-depth communication with the client is made to know the use they are currently making of their filters, as well as the needs of the future and their expectations. In gathering feedback from customers as well as issues encountered in the service after sales department, it can respond rapidly and give timely treatment or respond. Moreover, the feedback is also fed back to production and design departments to enhance the quality of products and services. The expert team examines the root of the problem and provides basic solutions to minimize the chance of repeating the same problem. The two complement one another and only then can we provide our customers with the highest quality customer service. This, in turn, can increase customer satisfaction and allow the business to expand.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy