Do you know what a filter is? A filter is an advanced technique that uses for removing undesired things from the liquid or gas. Does this, results in purer and more importantly safer to use substance. Anything that contains a filter is very crucial and we can find filters everywhere around. From potable water in our households and engine oils (in automotive industry) to gas scrubbers in factories, everything relies on filters unlike it is always not said – even hospitals depend on them for maintenance of sterile cleanliness. It may seem theoretically easy but when you have to do it manually, all the work can be very tedious and time-consuming!

However, the best solution to make that easier is Automatic Belt Filters. These are the filters which designed to run on its own. That way, no one needs to pay for your help so that they can hire others of the ilk at a discount. Filtering is much easier and quicker with this great technology. This not only saves time but also prevents human errors that occur in a manual filter.

They have the design that allows it to clean itself automatically using exclusive technology as well. According this they are able to observe in addition control the practice of filtration themself without asking someone else regarding help. It is indeed a smart process since it sees that the filtering goes through as fast and accurately as possible each-time. It can modify factors such as the rate and force at which the filtering occurs to optimize outcomes.

Automatic belt filters like that of Xuancheng are quite impressive due to their speedy functionality. One of these filters can handle and filter many gallons an hour. And this is the reason that they are able to clean liquid spills with ease, accurately and without any errors. It is widely used in industries where high speed of the filtering process as well Mono-layer filtration accuracy essential(parameters and units differ on case by case basis).

Different filters are available out of them Magmi data Filter is a preferred and has many benefits compared to manual filtering. They require significantly fewer interventions that, in turn, result to less possibility of human error. They also work extremely fast, resulting in quicker and more accurate parsing. Moreover, these filters are capable of filtering more liquid in a lesser time than what we can do using our hands.

Industrial filtration is the separation process in which one can separate unwanted particles and substances from a liquid or gas used in several industrial applications. This includes those in food and beverages, chemicals, among others. It can be a hard thing to do though, and requires an awful lot of experimentation. Thankfully, a device like Automatic Belt Filters can make this whole process far more simpler and convenient.

Automated Belt Filters: The Automated Belt Filter is the ideal option for multiple industries and offers variety of great features. They are easy to operate and work well without any issue. They are less frequent mistakes, because they require fewer handfeeding and workers can get increasing amount sloppy down doing a lot of physically exhausting work.

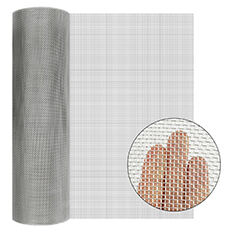

The filter of the extruder is constructed of high-quality steel and features tiny pores for filtering. This allows it to remove impurities and improve the quality and purity of the polymer. The design of the filter is designed to ensure that the flow of material ensures that it has a steady filtration efficiency throughout its passage this filter, reducing clogging and increasing production efficiency. The metal filter is highly resistant to resistance to wear, corrosion as well as high temperatures. As per the specific requirements of the customer and the specifications of the extruder specific filter solutions can be made to ensure a perfect match with existing equipment, and to provide the highest results in filtration. A high-performance filtration system reduces the time lost to delays caused by clogging of impurities and increases productivity.

Yangzhou Xuancheng Filter Screen Co., Ltd., a manufacturer of extruder screens, has been dedicated to the design and manufacture of plastic extrusion filter for a long time. They have built up an extensive amount of technical know-how and have gained experience in this business. They are extensively used in the manufacture of granulations that are modified with plastic, recycling granulations, extrusions made of films and sheets and many more along with filters for spinning chemical fibers. There is a variety of products available, such as filters, edging meshes, spot-welded meshes stainless steel mesh belts, reinforcing wire mesh, conveyor belts, mist eliminators etc. with a full range that can meet the various requirements of our customers. The company has supplied more than 500 of the most prestigious plastic, petrochemical, and metallurgical firms around the world. The company's name is widely acknowledged and is able to cover a variety of markets. The company has strong technical force, an extremely high degree of particularization, complete production equipment and an extensive testing process. The company has been accredited to ISO9001:2015 to ensure the stability and reliability of its product.

The company is equipped with a skilled after-sales team, utilizing the telephone, online customer support, social media and other methods of contact, they can quickly provide customers with technical support, consultation on products and tracking cargo along with troubleshooting services. The company will communicate with customers on a regular basis after they have purchased to find out their use of the filters currently and future expectations. The after-sales team can handle customer complaints and comments quickly by gathering the details. In addition, the feedback is also passed back to product design and production departments in order to improve the quality of the quality of products and services. The team of experts thoroughly investigates the cause of the issue, and then provides basic solutions to minimize the chance of repeating the same issue. Both complement each other and it is only then that we can offer our customers a high-quality after-sales experience. This in turn will strengthen customer loyalty and aid in helping the business increase its growth.

Customized services can include the choice of the filter material along with the pore size and shape and other elements. They also can provide custom-designed filters based on customer requirements and specifications for the extruder. Customized services allow for the optimization of parameters for filtering like structure and material, filtration precision and many more. This can improve the filter's filtration efficiency and life. The production is performed according to the actual needs of the customers, while avoiding unnecessary waste in order to help customers reduce costs. According to the specific needs and scenarios for customers, and taking into account the unique demands such as corrosion resistance, high temperature resistance, wear resistance for example. Choose the materials that have similar properties, like stainless steel, galvanized iron or galvanized iron. Create a filter design that is appropriate for the installation and operating conditions of your customer.

Copyright © Yangzhou Xuancheng Filter Screen Co., Ltd. All Rights Reserved - Privacy Policy